Spherical large particle size recycled aggregate preparation device and method

A technology for recycled aggregates and preparation devices, which can be applied in sustainable waste treatment, solid waste management, climate sustainability, etc. Effects of improved performance, improved recycling efficiency, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

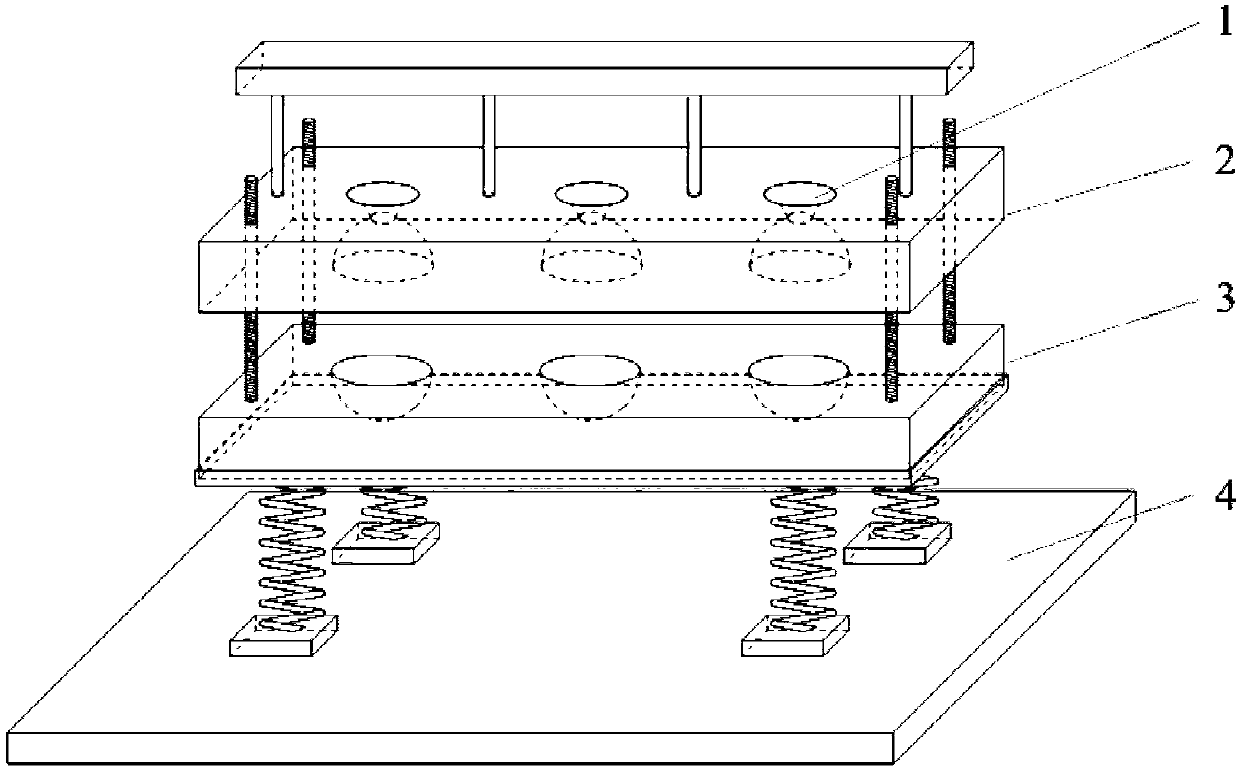

[0036] A spherical large particle size recycled aggregate preparation device, its structure schematic diagram is as follows figure 1 As shown, including a spherical aggregate processing device and a vibrating table 4, wherein:

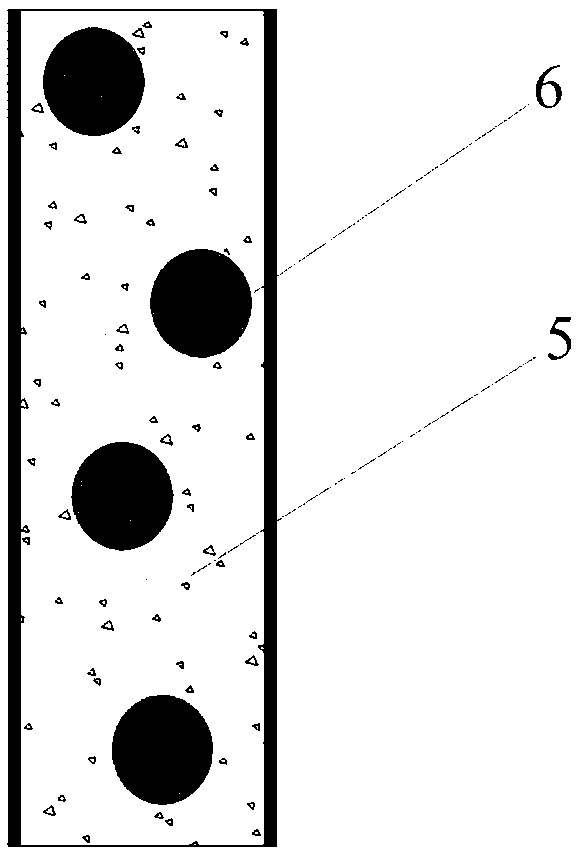

[0037] The spherical aggregate processing device includes an upper mold 2 and a lower mold 3, and the upper mold 2 and the lower mold 3 are respectively provided with hemispherical grooves. When the upper and lower molds are attached, the respective hemispherical grooves The grooves correspond one by one to form a spherical space;

[0038] A material inlet 1 is provided above the hemispherical groove of the upper mold;

[0039] The upper mold 2 and the lower mold 3 are connected by ordinary bolts or high-strength bolts.

[0040] A horizontal plate is arranged above the upper mold 2 for lifting the upper mold 2 .

[0041] The vibration table 4 is connected with the spherical aggregate processing device through a spring.

[0042] The size of the hemi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com