Production process of pouring foam concrete into hollow brick

A production process and technology for hollow bricks, which are applied in the field of self-insulation block preparation, can solve the problems of inconsistency between thermal insulation performance and brick body strength, poor bonding between foam concrete and brick body, and foam concrete is easy to collapse. Low density and the effect of improving friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

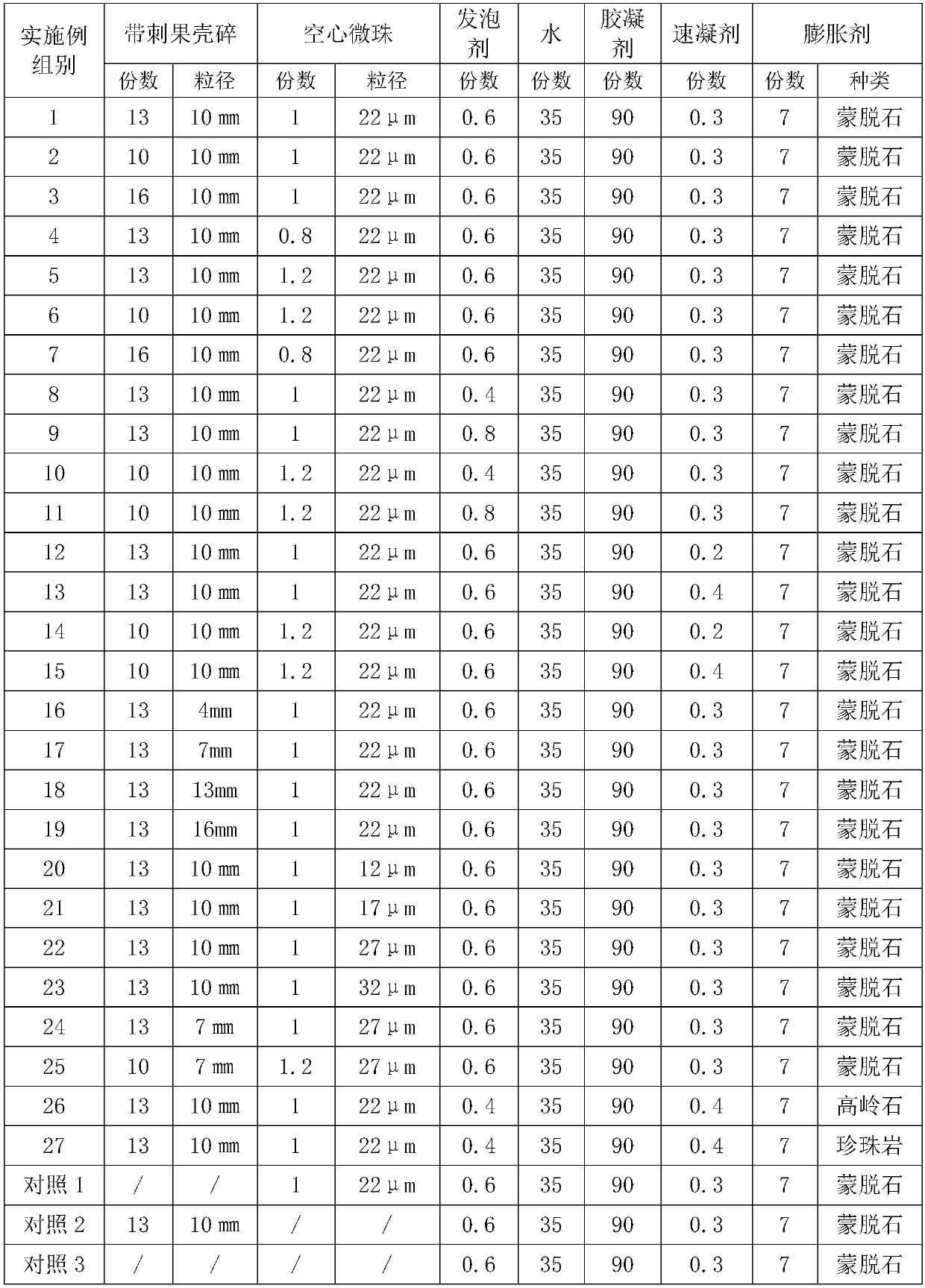

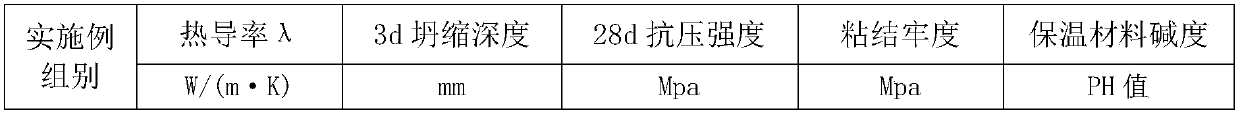

[0062] 1. Use the steps of the above-mentioned production process of pouring thermal insulation materials into hollow bricks to produce 30 groups of hollow brick samples filled with thermal insulation materials of different formulas. Each group of samples must have at least six bricks. Among them, the 28th, 29th, and 30th groups are blank control group.

[0063] The test raw materials of each embodiment are all commercially available: the hollow brick is a sintered brick with shale as the main raw material, the raw material of the broken prickly fruit shell is chestnut shell, the raw material of the hollow microsphere is hollow glass microsphere, and the foaming agent is dodecane Sodium phenyl sulfonate, the gelling agent is cement, and the quick-setting agent is alumina clinker-carbonate-based quick-setting agent.

[0064] The concrete formula of each embodiment insulation material is as shown in table 1.

[0065] The concrete formula of each embodiment insulation material o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com