PA66 composite material with excellent low-temperature toughness, low water absorption and high rigidity and preparation method thereof

A technology of PA66 and low-temperature toughness, which is applied in the field of nylon modification, can solve the problems of material softening, material toughness reduction, low water absorption, etc., and achieve the effect of expanding application fields, improving low-temperature toughness, and reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

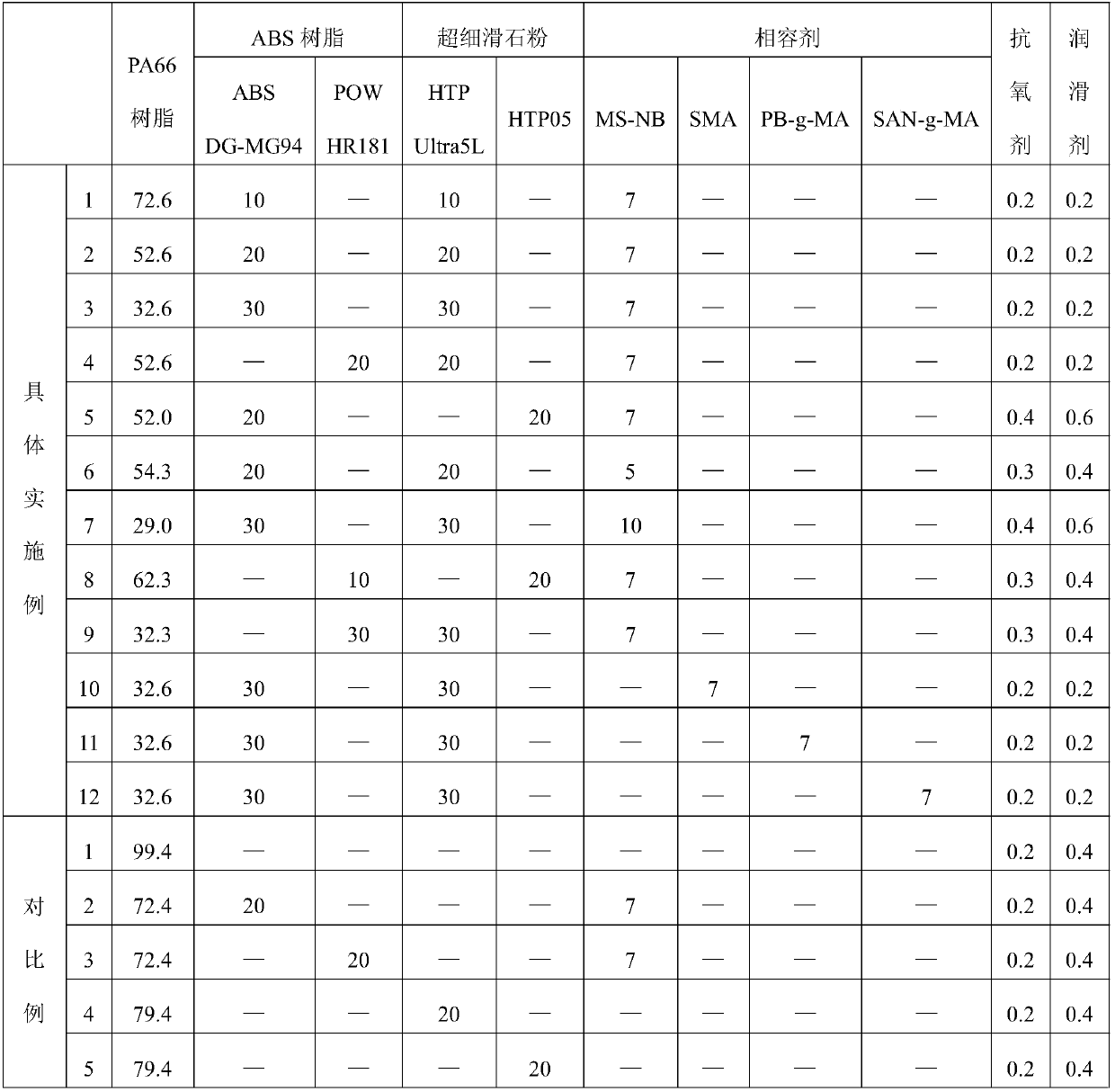

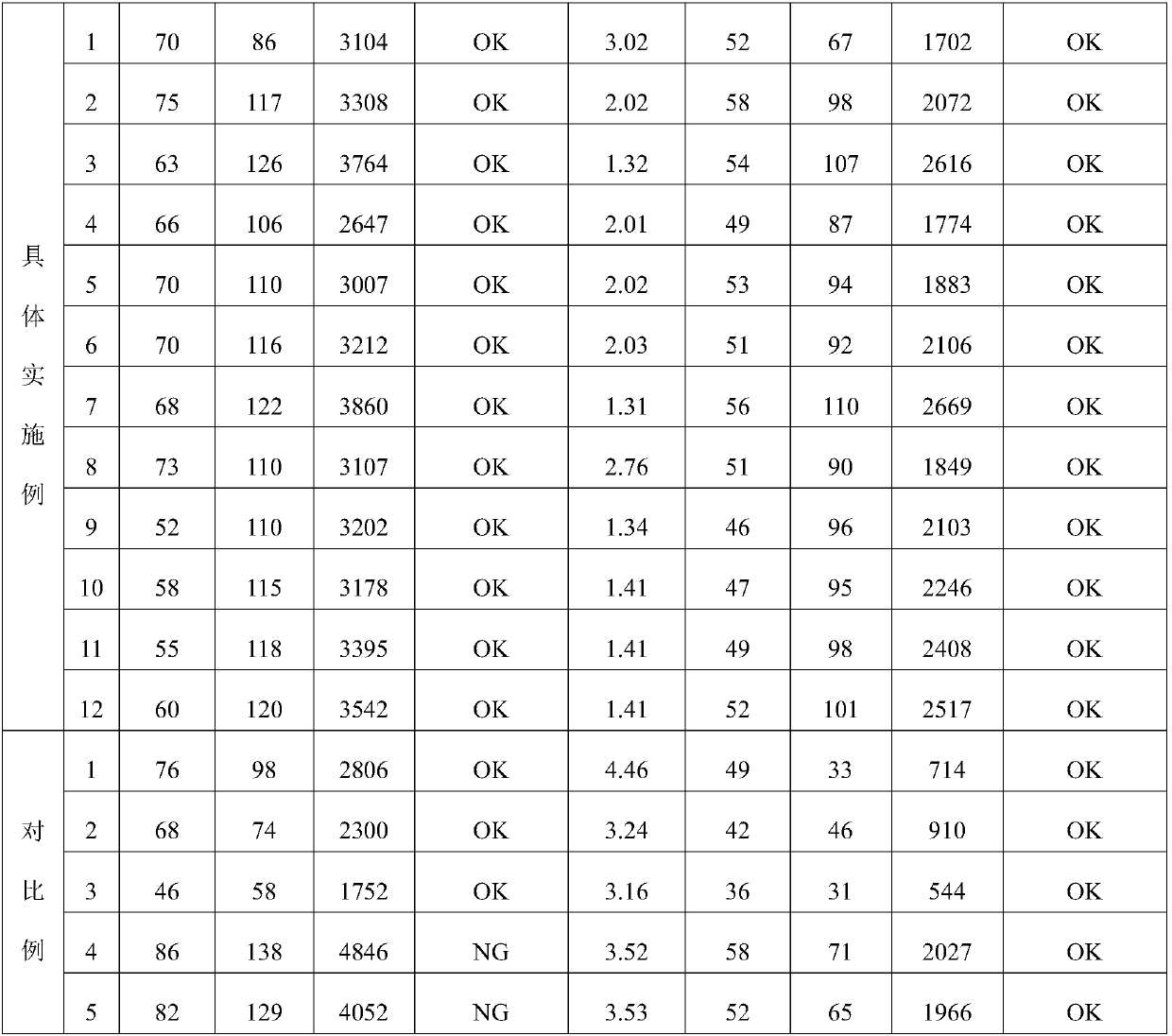

[0019] In order to be able to understand the technical means of the present invention more clearly and implement it according to the contents of the description, the specific embodiments of the present invention will be further described in detail below in conjunction with specific examples. The following examples are used to illustrate the present invention, but not to limit it scope of the invention.

[0020] The raw materials used in following specific examples and comparative examples are as follows:

[0021] PA66 resin: PA66EP-158, Zhejiang Huafeng Group.

[0022] ABS resin: ABS DG-MG94, Tianjin Dagu Chemical Co., Ltd.;

[0023] POW HR181, Kumho Petrochemical, Korea.

[0024] Lamellar structure filler: superfine talcum powder: HTP Ultra5L, 30,000 mesh, Italian Emi Fabi;

[0025] Superfine talcum powder: HTP05, 11000 mesh, Italy Yimi Fabi.

[0026] Compatibilizer: MS-NB, NEC;

[0027] SMA, commercially available;

[0028] PB-g-MA, commercially available;

[0029] SA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com