Active extraction method for ion type rare earth ore in-situ leaching

An ion-type rare earth ore and in-situ technology, applied in the direction of improving process efficiency, etc., can solve problems such as low recovery rate, long construction period, limited penetration hole depth and control range, etc., achieve high recovery rate, improve efficiency, reduce Effects of entry into strata and groundwater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

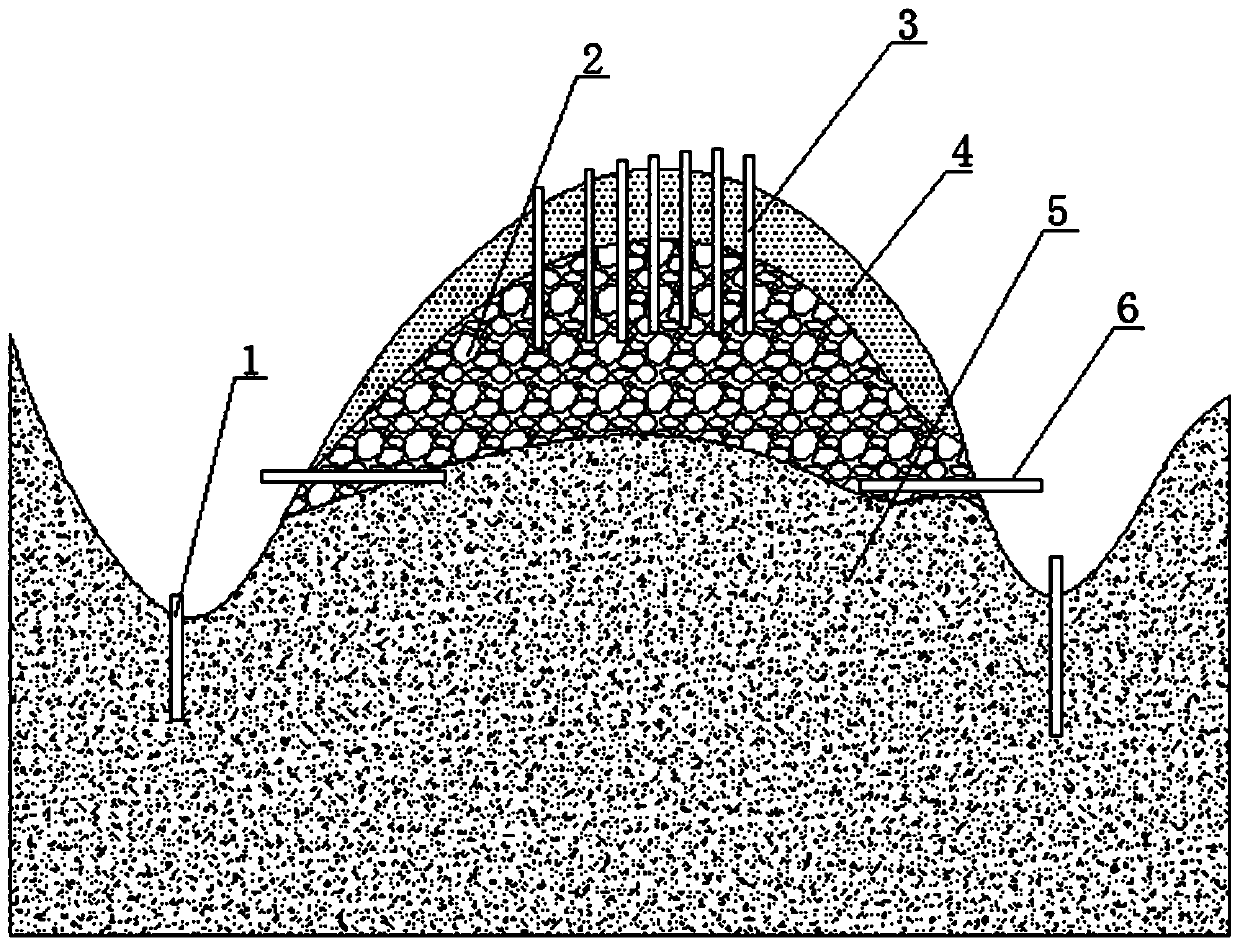

[0026] Such as figure 1 As shown, an active extraction method for in-situ leaching of ion-type rare earth ores is characterized in that: comprising the following steps:

[0027] S1. Establish a numerical model;

[0028] Arrange dense exploration holes in the mining area to explore the thickness of surface soil, thickness of ore layer, depth of bedrock, permeability coefficient, distribution of water seepage cracks and basic parameters of sand and soil particle size in the ore layer. Based on the above parameters, a numerical model is established and simulated in the numerical model Different injection hole spacing, extraction liquid injection rate and other parameters and combinations, comprehensively analyze the law of seepage field; according to the mining area topography,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com