Method for manufacturing semiconductor component for electric nozzle

A manufacturing method and semiconductor technology, applied to electrical components, circuits, jet propulsion devices, etc., can solve the problems of large energy loss and difficult processing, and achieve low energy loss, low processing difficulty, and prevent breakdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

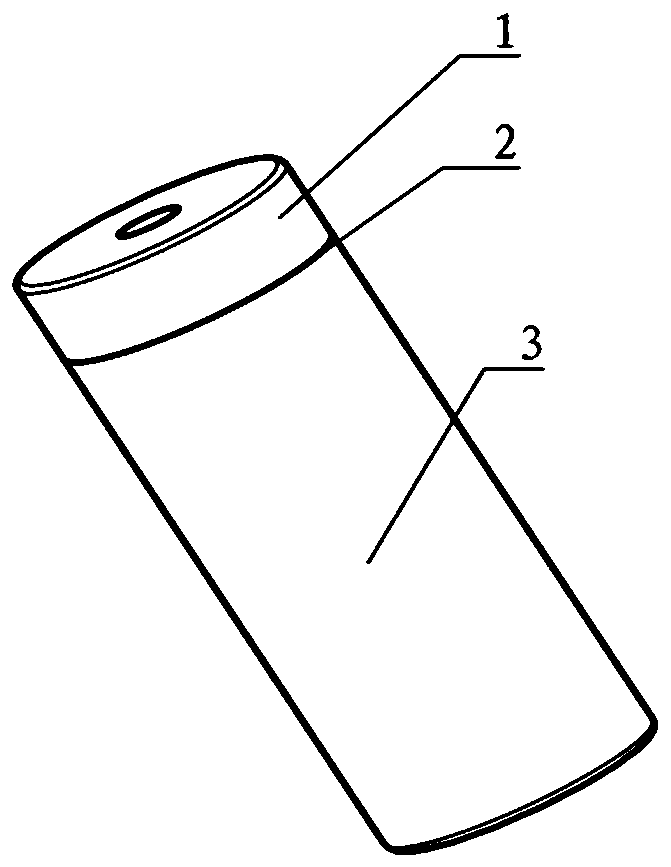

[0016] Such as figure 1 As shown, a method for manufacturing a semiconductor component for an electric nozzle described in this embodiment is characterized in that it includes the following steps: carbonizing the silicon carbide semiconductor 1, the sintered composite material 2, and the high-alumina porcelain 3 at room temperature Silicon semiconductor 1 is on top, sintered composite material 2 is in the middle, and high-alumina porcelain 3 is on the bottom. Preliminary molding is carried out to form a component to be sintered; the component to be sintered is sintered at 1800°C for two hours by hot isostatic pressing to make a semiconductor component .

[0017] In this embodiment, by integrally sintering the semiconductor and the insulator into a semiconductor component, avoiding the need to process and connect the silicon carbide semiconductor 1 and the insulator of the electric nozzle when installing in the electric nozzle, which reduces the difficulty of processing; by com...

Embodiment 2

[0019] On the basis of above-mentioned embodiment, propose embodiment 2, as figure 1 As shown, it is characterized in that: in the semiconductor component, the thickness of the silicon carbide semiconductor 1 is not greater than 5mm.

[0020] By controlling the ratio of silicon carbide semiconductor 1, sintered composite material 2, and high-alumina porcelain 3, the thickness of silicon nitride semiconductor is not greater than 5mm, and the overall height of the semiconductor component is filled by adjusting the thickness of high-alumina porcelain 3. It meets the needs of electric nozzles for semiconductor components, and has good corrosion resistance. At the same time, it can reduce the possible internal leakage current and further reduce the energy loss of electric nozzles.

[0021] In this embodiment, the use ratio of the sintered composite material 2 is relatively flexible. It is only necessary to make the sintered composite material 2 between the silicon carbide semicondu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com