A Stator Excited Linear Rotary Motor Structure

A technology of rotating motors and stators, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., and can solve the problems of linear rotation two-degree-of-freedom motor control theory and technology, increased system volume and weight, special stator and mover structures, etc. problem, to achieve the effect of convenient installation of linear and rotary position detectors, good fault tolerance performance, and high air gap magnetic density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below through specific embodiments.

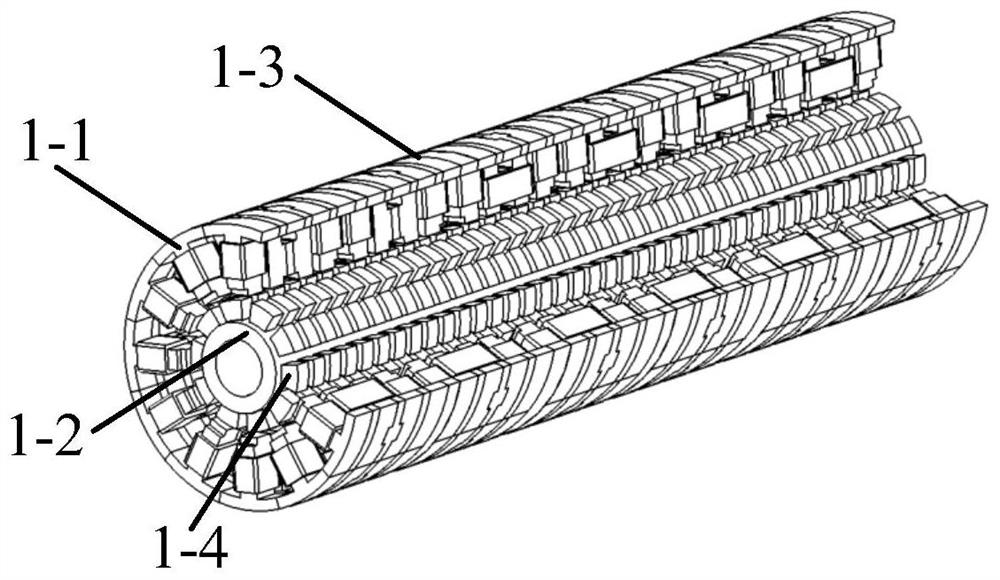

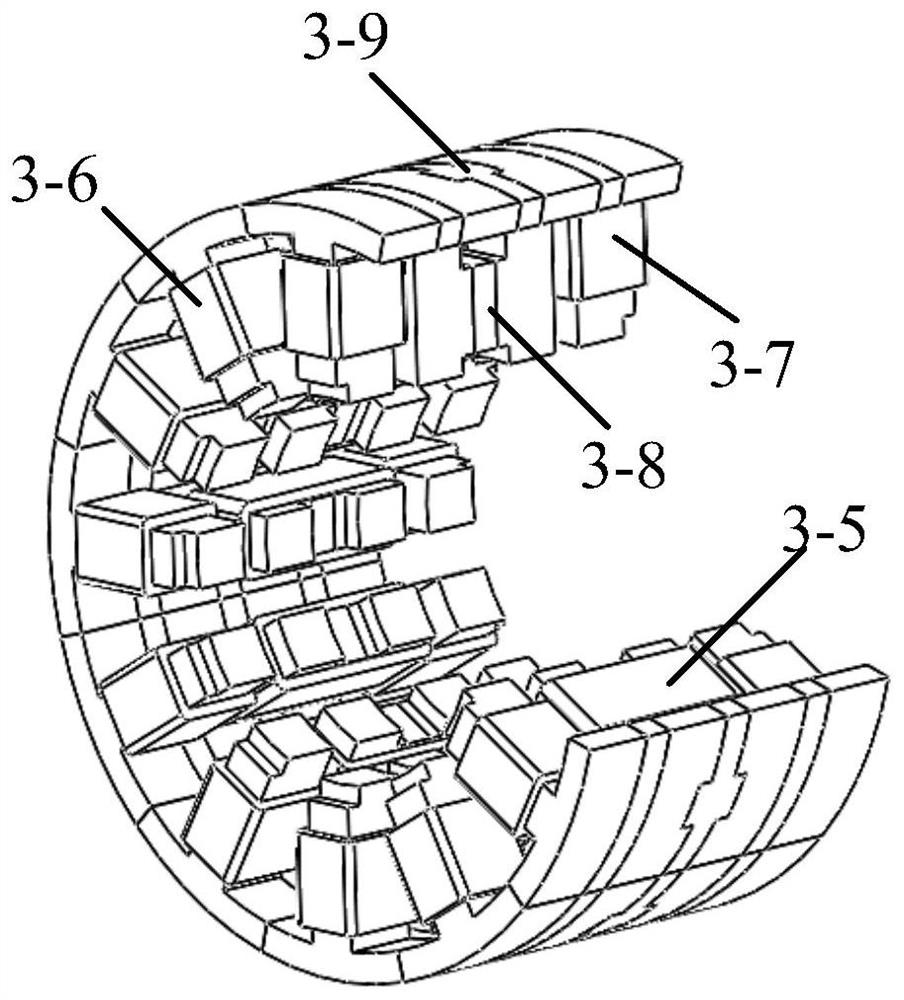

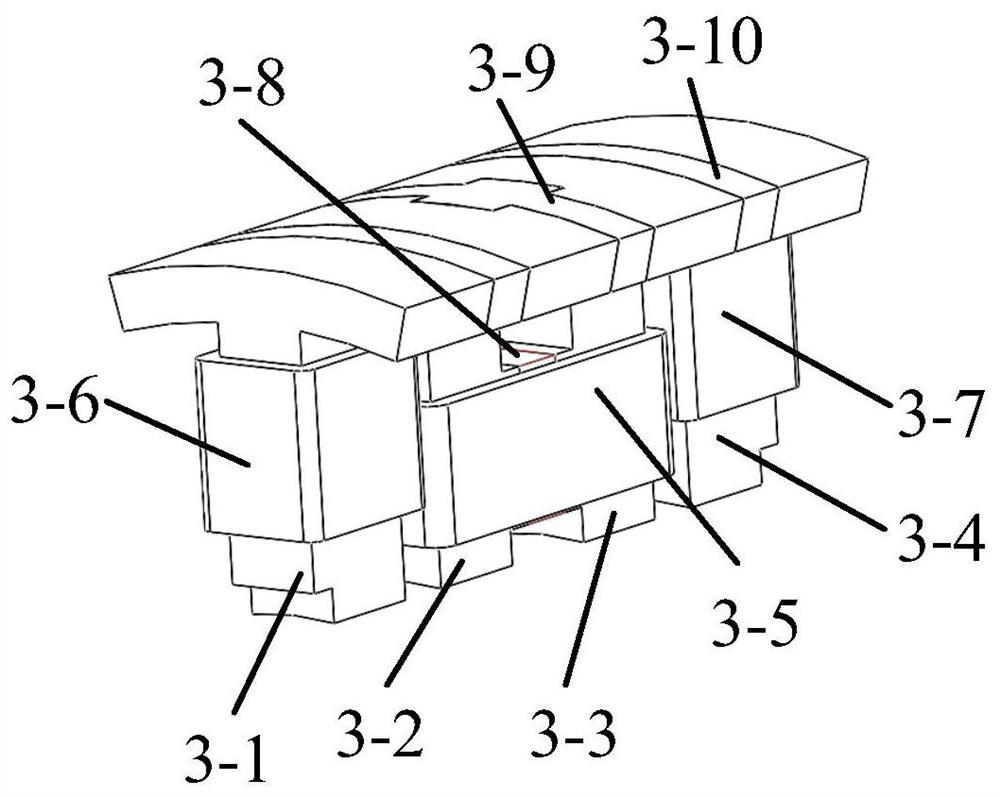

[0030] The technical solution adopted in the present invention is to use the "minimum reluctance principle" and "magnetic flux switching" principle to construct a two-degree-of-freedom drive for linear rotation, and arrange permanent magnets and windings on the stator, and the motor has radial and axial double salient poles structure. A stator excitation type linear rotary motor structure of the present invention has the following features: the stator is composed of m stator modules axially combined, and magnetic isolation rings are arranged between the stator modules; the mover is composed of n mover modules Combined in the axial direction; rings are arranged between two mover modules.

[0031] The stator module is composed of i stator units along the circumferential direction; the circumferential angle occupied by the stator units is 360° / i; the stator unit consists of a T-shaped t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com