Desulfurization, denitrification, dust removal and waste heat recovery integrated comprehensive technology for waste gas in furnace

A technology of waste gas desulfurization and waste heat recovery, applied in the chemical industry, climate sustainability, chemical instruments and methods, etc., can solve complex problems, achieve ultra-low emissions, strong economy and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

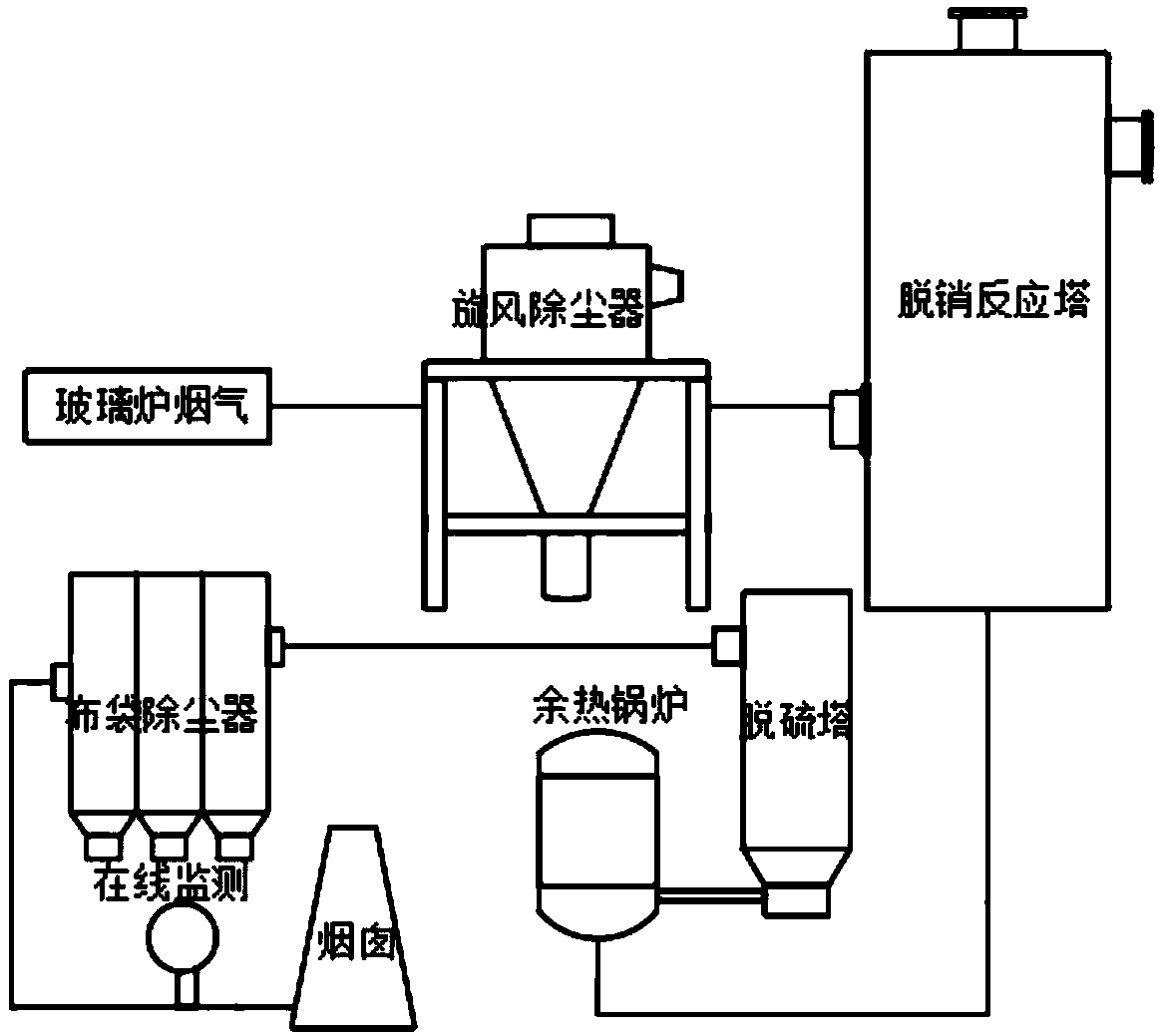

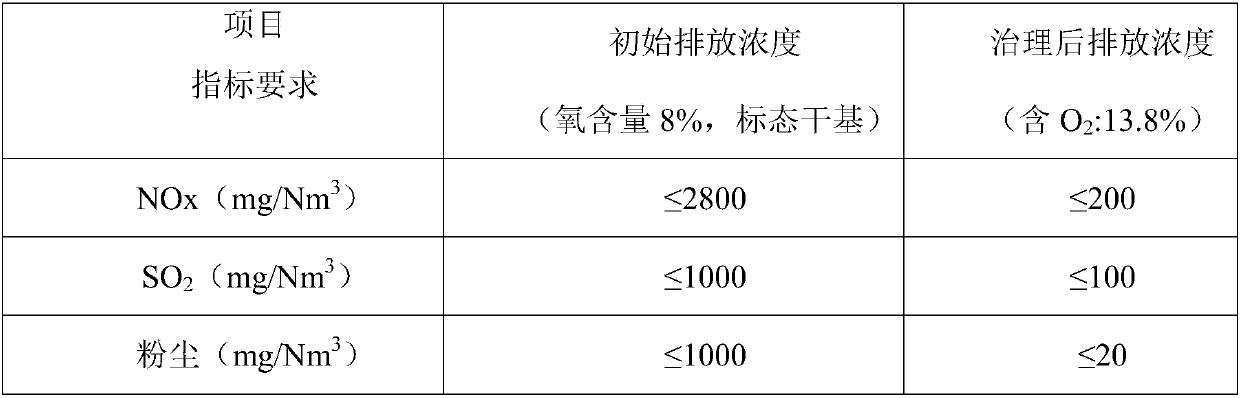

[0020] Kiln exhaust gas desulfurization, denitrification, dust removal and waste heat recovery integrated comprehensive technology, the process flow is as follows;

[0021] Step 1: Pre-dust removal and desulfurization: the exhaust gas from the kiln flue enters the dust collector and puts quicklime CaO into the dust collector; a large amount of smoke and dust will be generated during the operation of the glass kiln, and the sodium ions in the glass kiln are likely to react with the components of the catalyst at high temperature and cause poisoning Phenomenon, if the dust removal treatment is not carried out, or the dust removal effect is not good, it will cause smoke and dust to accumulate on the surface of the catalyst, reducing the denitrification efficiency. Agent NH 3 , will directly interact with SO in the flue gas 2 , SO 3 The reaction produces NH 4 HSO 4 , with wet viscosity, attached to the surface of the catalyst, blocking the honeycomb pores, the main reaction:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com