Preparation method of a corrugated structure cermet-based zeolite adsorption material

A cermet-based, adsorption material technology, applied in non-metallic elements, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of low mechanical strength, low desorption efficiency, structural collapse, etc., to overcome performance improvement, desorption The effect of short attachment time and light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

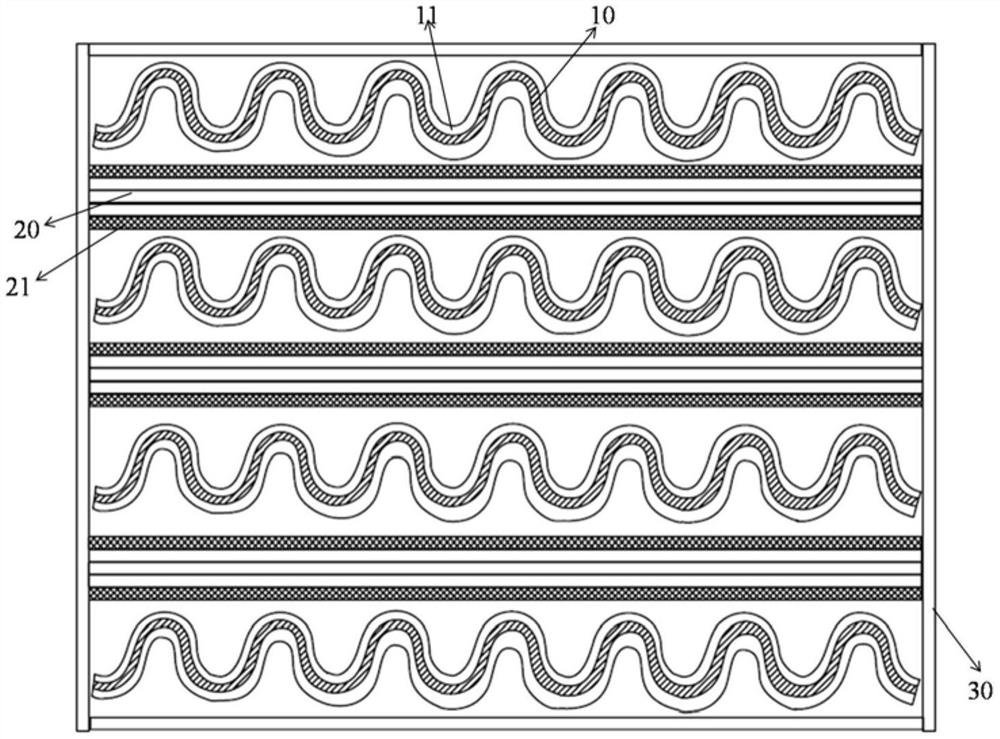

[0024] A method for preparing a cermet-based zeolite adsorption material with a corrugated structure, comprising the following steps:

[0025] A1. Degreasing and silane passivation treatment are carried out on the surface of 2 groups of corrugated FeCrAl alloy sheets with a thickness of 10 μm, and 1 group of glass fiber paper is arranged between adjacent FeCrAl alloy sheets to form a sandwich structure, wherein , each set of glass fiber paper includes 1 layer of glass fiber paper;

[0026] A2. Dip-coat the sandwich structure in step A1 in the zeolite slurry as a whole, and blow off the excess slurry, so that the upper and lower surfaces of the FeCrAl alloy sheet are coated with the first zeolite slurry layer with a thickness of 100 μm, and the upper and lower sides of the glass fiber paper The surface is covered with a second zeolite slurry layer with a thickness of 100 μm, then dried at 120-240°C, and finally baked at 240-300°C for 2-6 hours;

[0027] A3. After the baking is...

Embodiment 2

[0029] A method for preparing a cermet-based zeolite adsorption material with a corrugated structure, comprising the following steps:

[0030] B1. Heat-treat the surface of 4 groups of corrugated FeCrAl alloy sheets with a thickness of 100 μm at 800°C for 2 hours, and place 3 groups of glass fiber paper between adjacent FeCrAl alloy sheets to form a sandwich structure, wherein each The set of glass fiber paper includes 3 layers of glass fiber paper;

[0031] B2. Dip-coat the sandwich structure in step B1 in the zeolite slurry as a whole, and blow off the excess slurry, so that the upper and lower surfaces of the FeCrAl alloy sheet are coated with the first zeolite slurry layer with a thickness of 500 μm, and the upper and lower sides of the glass fiber paper The surface is covered with a second zeolite slurry layer with a thickness of 500 μm, and then dried at 120-240°C, and finally baked at 240-300°C for 2-6 hours;

[0032] B3. After the baking is completed, the sandwich str...

Embodiment 3

[0038] A method for preparing a cermet-based zeolite adsorption material with a corrugated structure, comprising the following steps:

[0039] C1. Perform degreasing and silane passivation treatment on the surface of two groups of corrugated aluminum alloy sheets with a thickness of 10 μm, and place one group of glass fiber paper between adjacent aluminum alloy sheets to form a sandwich structure, wherein each The set of glass fiber paper includes 1 layer of glass fiber paper;

[0040] C2. Dip-coat the sandwich structure in step C1 in the zeolite slurry as a whole, and blow off the excess slurry, so that the upper and lower surfaces of the aluminum alloy sheet are coated with the first zeolite slurry layer with a thickness of 1000 μm, and the upper and lower surfaces of the glass fiber paper Coated with a second zeolite slurry layer with a thickness of 1000 μm, then dried at 120-240°C, and finally baked at 240-300°C for 2-6 hours;

[0041] C3. After the baking is completed, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com