Automatic whole-row cover feeding device for plastic cover

A technology of plastic cover and cover feeding, applied in the field of pharmaceutical packaging, can solve the problems of low production efficiency, inconvenient production, and disordered cover, and achieve the effects of improving production efficiency, simple structure and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

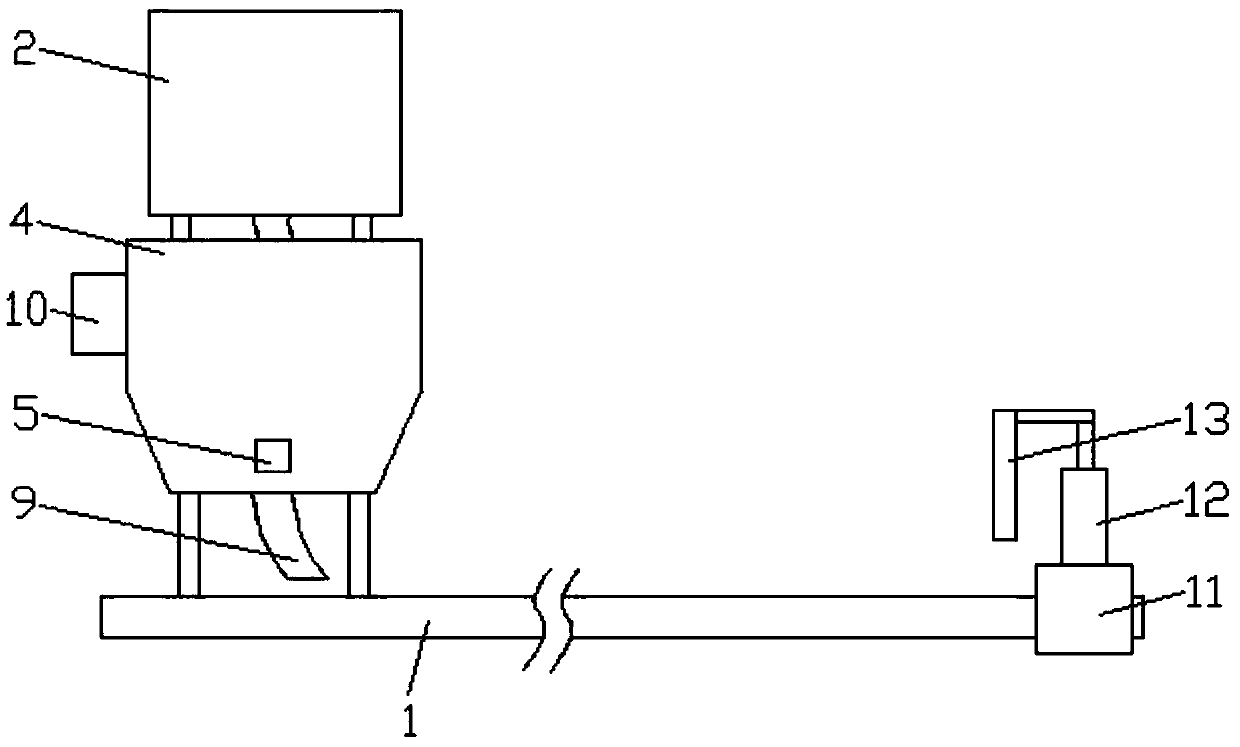

Embodiment 1

[0038] The present embodiment also includes a vacuum pump 10, the vacuum pump 10 is arranged on the outer wall of the whole cover box 4, the vacuum pump 10 communicates with the whole cover box 4, and the whole cover box 4 is evacuated by the vacuum pump 10, so that a negative pressure is formed in the whole cover box 4, The bottle caps in the bottle cap storage box 2 are sent to the full cap box 4 by using the pressure difference between the full cap box 4 and the cap storage box 2, which is easy to operate and does not need to manually feed the caps, saving time and effort.

Embodiment 2

[0040] The difference between this implementation and Embodiment 1 is that the vacuum pump 10 is not provided, the cap storage box 2 is arranged above the full cap box 4 through a bracket, and the bottle caps in the cap storage box 2 automatically slide down into the full cap box 4 by their own gravity. . In comparison, this embodiment is more convenient and less costly than Embodiment 1.

[0041] It should be noted that, the side wall of the cap storage box 2 is provided with a feeding port for manually replenishing bottle caps periodically, and an openable and closable cover is provided at the feeding port.

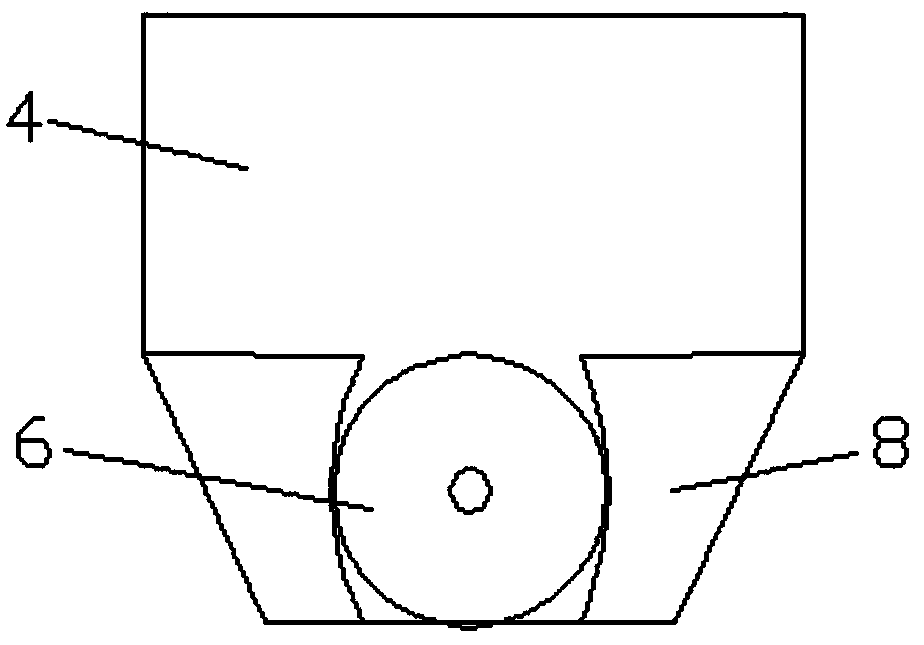

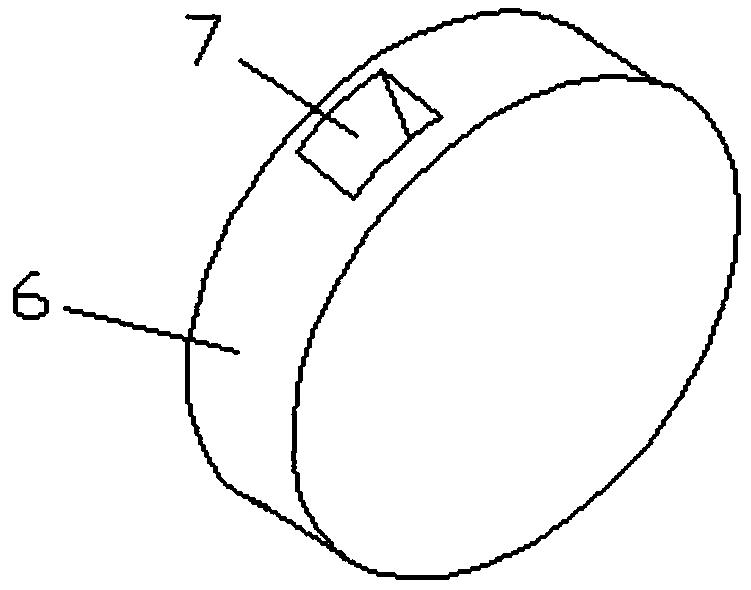

[0042]In addition, the advantage of the opening at the bottom of the whole lid box 4 is a strip opening, the length of the strip opening matches the diameter of the turntable 6, and the length of the strip opening is slightly greater than the diameter of the turntable 6 to ensure that the turntable 6 can rotate in the strip opening The width of the strip-shaped opening...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap