A kind of manufacturing equipment and manufacturing method of ultrafine aluminum hydroxide

A technology for ultra-fine aluminum hydroxide and manufacturing equipment, which is applied in the fields of alumina/hydroxide preparation, chemical instruments and methods, aluminum compounds, etc. Large and other problems, to achieve the effect of reducing equipment investment, uniform particle size distribution, and high mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

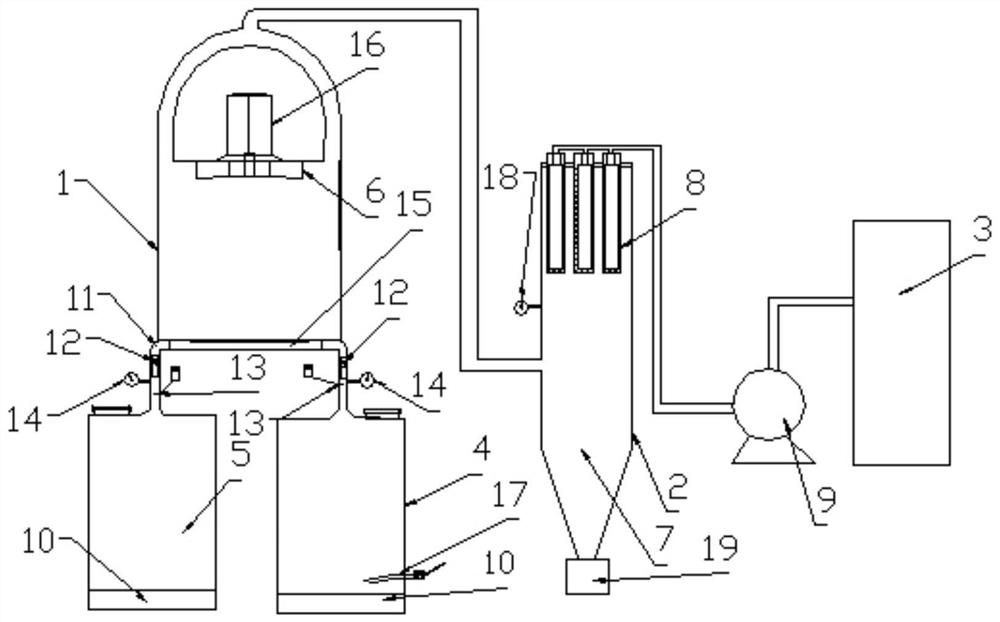

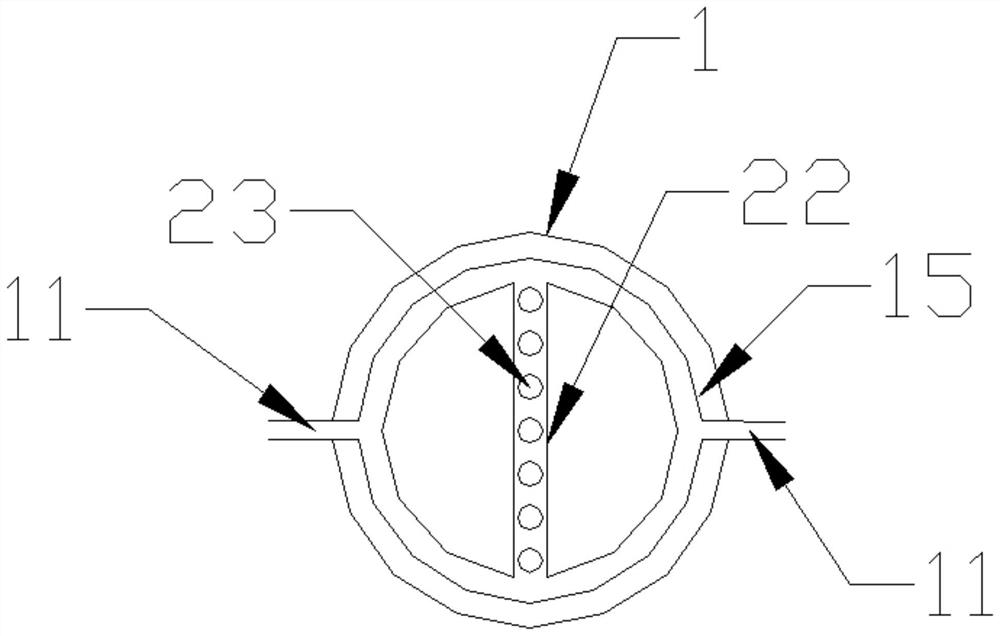

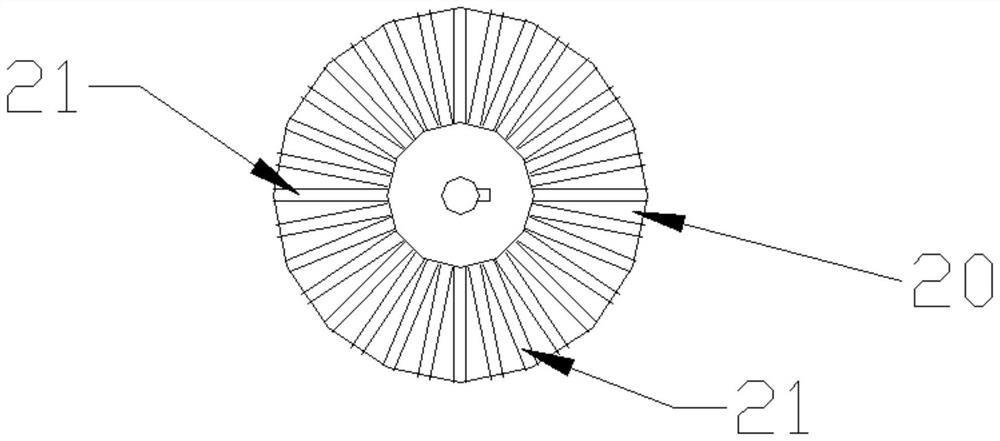

[0046] A kind of ultra-fine aluminum hydroxide manufacturing equipment, it comprises reactor 1, collection device 2 and absorption device 3, and described reactor 1 is communicated with aluminum salt tank 4 and water storage tank 5, and reactor 1 is provided with turbine 6 , the top side of the reactor 1 communicates with the collection device 2, the collection device 2 includes a cyclone dust collector 7, and the top of the cyclone dust collector 7 is provided with a dust collection bag 8, and the interior of the dust collection bag 8 communicates with the induced draft fan 9 through a pipeline, The induced draft fan 9 communicates with the absorption device 3, and the aluminum salt tank 4 and the water storage tank 5 are equipped with a heating device 10, and the aluminum salt tank 4 and the water storage tank 5 are connected with the reactor 1 through a titanium tube 11, and the titanium tube 11 is provided with a volume flow meter 12, a temperature sensor 13 and a pressure ...

Embodiment 2

[0061] A kind of ultra-fine aluminum hydroxide manufacturing equipment, it comprises reactor 1, collection device 2 and absorption device 3, and described reactor 1 is communicated with aluminum salt tank 4 and water storage tank 5, and reactor 1 is provided with turbine 6 , the top side of the reactor 1 communicates with the collection device 2, the collection device 2 includes a cyclone dust collector 7, and the top of the cyclone dust collector 7 is provided with a dust collection bag 8, and the interior of the dust collection bag 8 communicates with the induced draft fan 9 through a pipeline, The induced draft fan 9 communicates with the absorption device 3, and the aluminum salt tank 4 and the water storage tank 5 are equipped with a heating device 10, and the aluminum salt tank 4 and the water storage tank 5 are connected with the reactor 1 through a titanium tube 11, and the titanium tube 11 is provided with a volume flow meter 12, a temperature sensor 13 and a pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com