A deep nitrogen and phosphorus removal process based on sbbr

A deep denitrification and process technology, applied in the field of environmental engineering, can solve problems such as high operating costs, unqualified effluent quality, and difficult operation management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

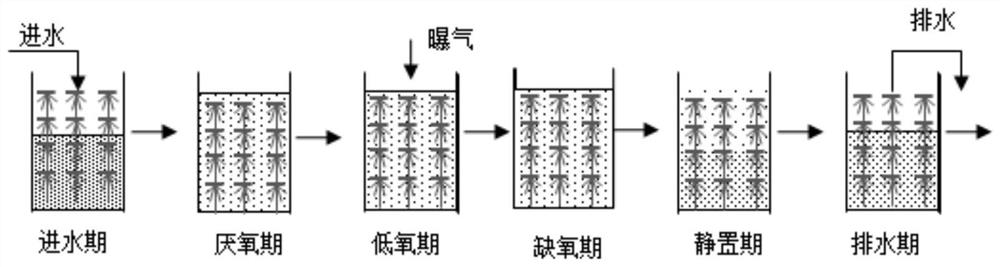

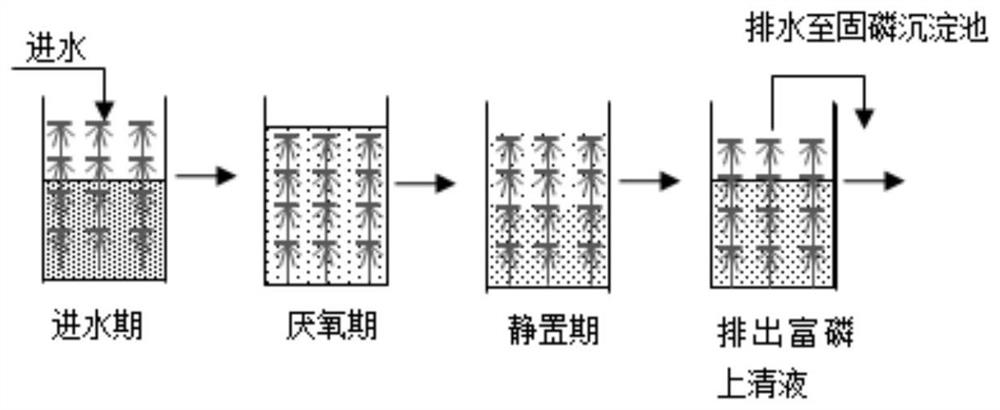

[0025] Combine below figure 1 , figure 2 The process flow of the present invention is further described in detail, which is an explanation of the present invention rather than a limitation.

[0026] Such as figure 1 , the deep denitrification and dephosphorization process based on SBBR of the present invention, the complete process of a cycle comprises the following steps:

[0027] Step 1: Pump the sewage to be treated into the SBBR reactor. The general domestic sewage water quality indicators are: chemical oxygen demand COD = 300 ~ 500mg / L, biochemical oxygen demand BOD 5 =180~300mg / L, total nitrogen TN=60~80mg / L, ammonia nitrogen=40~60mg / L, total phosphorus TP=5~10mg / L. According to the capacity of the equipment, stop after reaching the predetermined water filling volume;

[0028] Step 2: Turn on the agitator to mix the sewage in the SBBR reactor with the biofilm evenly and make the SBBR reactor operate in the mode of anaerobic → low oxygen → anoxic; the anaerobic mode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com