Preparation method and rapid infiltration system for biochar immobilized microbial filler

A technology of microorganisms and biochar, which is applied in the direction of using microorganisms, granular microbial carrier treatment, immobilization on or in inorganic carriers, etc., can solve the problem that the total nitrogen index of domestic sewage cannot be reached, and the artificial rapid infiltration system takes up Large land area and other problems, to achieve the effect of ensuring the infiltration speed and ammonia nitrogen removal capacity, rich variety and quantity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

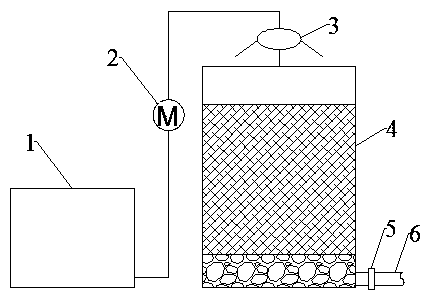

Image

Examples

Embodiment 1

[0034] A preparation method of biochar immobilized microbial filler mainly comprises the following steps:

[0035] Step E1: The biomass raw material is rice straw, after removing large particles of impurities, air-dried and pulverized into 3 cm by a pulverizer, and placed for use; the oxygen-limited pyrolysis method is used to prepare biochar in a muffle furnace, and an appropriate amount of biomass is weighed in a crucible, Compact, cover and place in a temperature-programmed muffle furnace, crack at a temperature of 300-700°C for 6 hours, take it out after cooling, grind and pass through a 10-mesh sieve for use;

[0036] Step E2: Take the filler that has been running stably for many years from the artificial rapid infiltration system (CRI system), and store it in a refrigerator at 4°C until use; take about 2g of the preserved filler, inoculate it in sterile water under aseptic operation, and incubate at 35°C, 140r / Under the condition of shaking for 3 hours, let it stand sti...

Embodiment 2

[0044] A preparation method of biochar immobilized microbial filler mainly comprises the following steps:

[0045] Step E1: The biomass raw material is rice straw, after removing large particles of impurities, air-dried and pulverized into 5 cm by a pulverizer, and placed for use; the oxygen-limited pyrolysis method is used to prepare biochar in a muffle furnace, and an appropriate amount of biomass is weighed in a crucible, Compact, cover and place in a temperature-programmed muffle furnace, crack at a temperature of 300-700°C for 6 hours, take it out after cooling, grind and pass through a 10-mesh sieve for use;

[0046] Step E2: Take the filler that has been running stably for many years from the artificial rapid infiltration system (CRI system), and store it in a refrigerator at 4°C until use; take about 2g of the preserved filler, inoculate it in sterile water under aseptic operation, and incubate at 35°C, 140r / Under the condition of shaking for 3 hours, let it stand sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com