Green preparation method of magnesium glycinate

A technology of magnesium glycinate and glycine, which is applied in the preparation of organic compounds, chemical instruments and methods, and cyanide reaction preparation, etc., can solve the problems of unstable process, waste of raw materials, low utilization rate of raw materials, etc. The effect of saving production cost and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A green preparation method of magnesium glycinate, comprising the following steps:

[0028] A. Add glycine and water to the reaction kettle, heat up to dissolve glycine, wherein water is preferably deionized water, and the mass volume ratio of glycine to water is 0.3-0.6g:1mL, preferably 0.55g:1mL, more preferably 0.5g: 1mL;

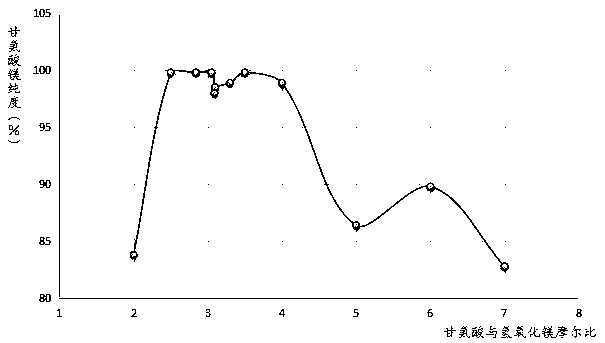

[0029] B. Add magnesium hydroxide when the temperature rises to 83-87°C, and remove the insoluble matter by suction filtration after reacting for 2-3 hours to obtain the filtrate; wherein the temperature is preferably raised to 85°C, and magnesium hydroxide is added in 2-3 times, and the reaction time is 2.5h; the molar ratio of glycine and magnesium hydroxide is 2.5-4:1, preferably 3.5:1, more preferably 3:1.

[0030] C. filtrate is down to room temperature, then suction filtration obtains magnesium glycinate wet product and circulation mother liquor;

[0031] D. Vacuum drying the wet product of magnesium glycinate at 105° C. for 2 hours to obt...

Embodiment 1

[0034] Take 500g (6.7mol) of raw material glycine and add 1000mL of deionized water, stir and heat up to 85°C. After the glycine is basically dissolved, add 130g (2.2mol) of magnesium hydroxide measured in two times, react for 2h, filter out insoluble matter, and wait for After the filtrate was cooled to room temperature, suction filtration obtained 320 g of magnesium glycinate wet product, and about 1200 mL of circulating mother liquor. After the wet product of magnesium glycinate is vacuum-dried at 105°C for 2 hours, the dry weight is 290g, wherein the magnesium content is 11.5%, and the magnesium glycinate content is 99.8%, which meets the molecular formula (C 2 h 5 NO 2 ) 2 Mg 2H 2 O content requirements. (In this example, the molar ratio of glycine to magnesium hydroxide is 3.05:1, and the mass volume ratio of glycine to water is 0.5:1g / mL)

Embodiment 2

[0036] Take 120mL of the mother liquor in Example 1, add 33.8g (0.45mol) of glycine, stir and heat up to 83°C, wait until the glycine is basically dissolved, add 13g (0.22mol) of magnesium hydroxide measured in two times, react for 2.5h, and filter out the insoluble After the filtrate is down to room temperature, suction filtration obtains 52g of magnesium glycinate wet product, about 100mL of circulating mother liquor, after 105 ℃ vacuum drying of magnesium glycinate wet product, dry weight is 45.2g, wherein magnesium content is 11.5%, and magnesium glycinate content is 99.8%, yield 98.7%, meet molecular formula (C 2 h 5 NO 2 ) 2 Mg 2H 2 O content requirements. (In this example, the molar ratio of glycine to magnesium hydroxide is 2.84:1, and the mass volume ratio of glycine to water is 0.55:1g / mL)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com