silicate silicone noise-reduction aid and preparation of noise-reducing low-odor PC/ABS alloy

A technology of silicate and noise-reducing additives, which is applied in the field of preparation of silicate-silicone noise-reducing additives. It can solve the problems of processability and aesthetic requirements of unfavorable product parts, achieve excellent mechanical properties, improve mechanical strength, The effect of reducing odor emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

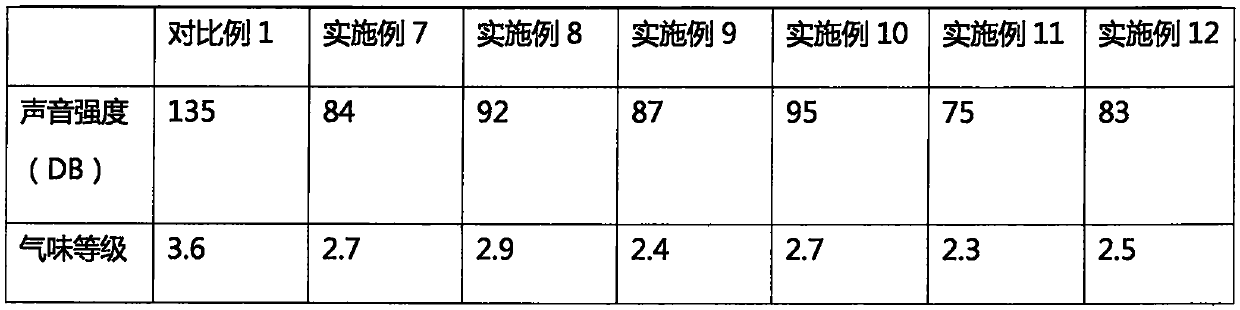

Examples

Embodiment 1

[0033] In this example, the silicate silicone noise reduction additive is prepared as follows:

[0034] First, 7 kg of montmorillonite (interlayer spacing 2.8 nm) and 0.5 kg of flake graphite were added to a ball mill, mixed and ball milled for 2 hours to obtain uniformly mixed materials. After the material is taken out, put it into a low-speed mixer with 1kg of coupling agent, and mix for 10-30 minutes. Put the mixed material and 1 kg of silicone liquid into an internal mixer at a temperature of 190°C, melt and banbury for 10 minutes, and granulate to obtain a silicate silicone noise reduction additive.

Embodiment 2

[0036] In this example, the silicate silicone noise reduction additive is prepared as follows:

[0037] First, 7 kg of montmorillonite (interlayer distance 2.8 nm) and 0.5 kg of vermiculite were added to a ball mill, mixed and ball milled for 2 hours to obtain uniformly mixed materials. After the material is taken out, put it into a low-speed mixer with 1kg of coupling agent, and mix for 10-30 minutes. Put the mixed material and 1 kg of silicone liquid into an internal mixer at a temperature of 190°C, melt and banbury for 10 minutes, and granulate to obtain a silicate silicone noise reduction additive.

Embodiment 3

[0039] In this example, the silicate silicone noise reduction additive is prepared as follows:

[0040] First, add 7kg halloysite and 0.5kg flake graphite into the ball mill, mix and ball mill for 1 hour to obtain a uniformly mixed material. After the material is taken out, put it into a low-speed mixer with 1kg of coupling agent, and mix for 10-30 minutes. Put the mixed material and 1 kg of silicone liquid into an internal mixer at a temperature of 190°C, melt and banbury for 15 minutes, and granulate to obtain a silicate silicone noise reduction additive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com