A kind of glue improver for kraft paper and white kraft paper and preparation method thereof

A technology of improver and kraft paper, applied in the field of papermaking, can solve problems such as uneven distribution of ink and affecting the appearance of printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

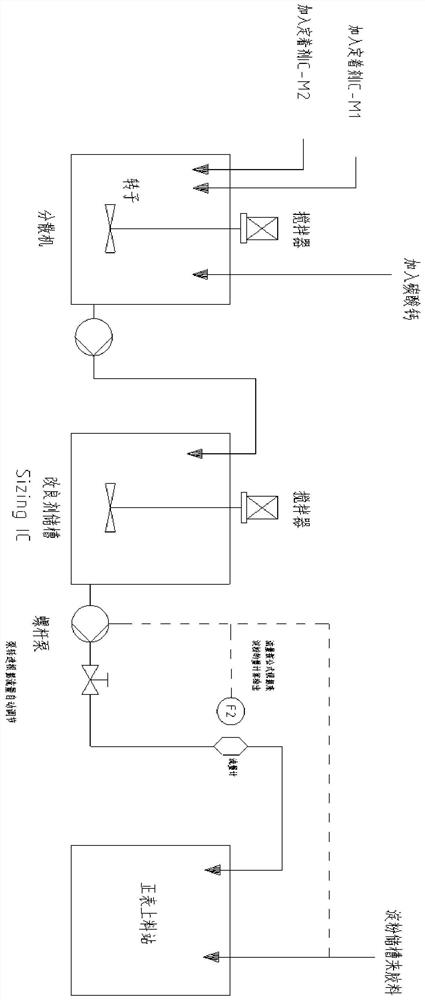

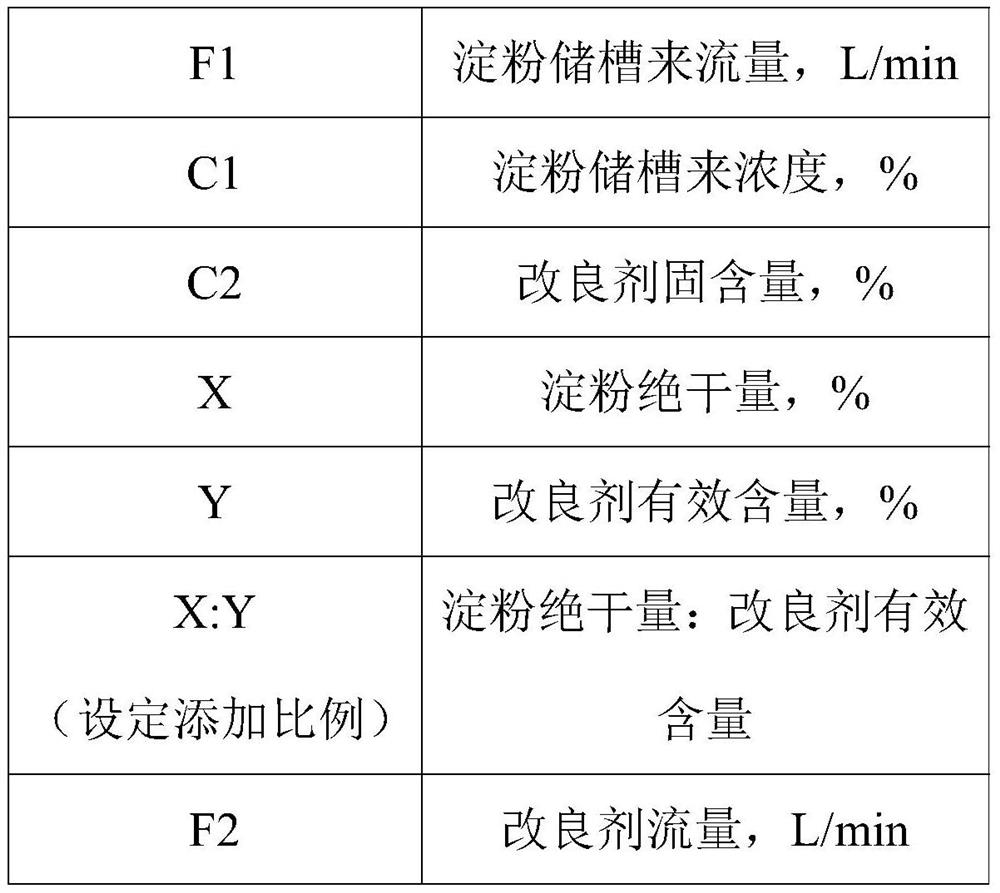

Method used

Image

Examples

Embodiment 1

[0052] The present embodiment provides a kind of preparation method of the surface glue glue improver that is used for kraft paper and white kraft paper, described method is:

[0053] The 350 parts by weight of water is mixed with 150 parts by weight of light powdered calcium carbonate, stirred at 800 rpm for 50 minutes to form an emulsion; the emulsion is mixed with 50 parts by weight of dispersant at 300 rpm for 20 minutes, and then mixed with 50 parts by weight of One part of the fixing agent was stirred and mixed for 20 min at a rotating speed of 300 rpm to obtain the modifier.

[0054] The solid content of the prepared improver was 35%.

Embodiment 2

[0056] The present embodiment provides a kind of preparation method of the surface glue glue improver that is used for kraft paper and white kraft paper, described method is:

[0057] The water of 320 parts by weight is mixed with 160 parts by weight of light powdered calcium carbonate, and stirred at 900 rpm for 45 minutes to form an emulsion; the emulsion is mixed with 52 parts by weight of dispersant at 350 rpm for 12 minutes, and then mixed with 52 parts by weight of One part of the fixing agent was stirred and mixed for 12 minutes at a rotating speed of 350 rpm to obtain the modifier.

[0058] The solid content of the prepared improver is 40%.

Embodiment 3

[0060] The present embodiment provides a kind of preparation method of the surface glue glue improver that is used for kraft paper and white kraft paper, described method is:

[0061] The 300 parts by weight of water is mixed with 170 parts by weight of light calcium carbonate powder, stirred at 1000 rpm for 40 minutes to form an emulsion; the emulsion is mixed with 55 parts of dispersant at 400 rpm for 15 minutes, and then mixed with 55 parts by weight of One part of the fixing agent was stirred and mixed for 15 min at a rotating speed of 400 rpm to obtain the modifier.

[0062] The solid content of the prepared improver was 45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com