Lightweight printing paper and preparation method thereof

A printing paper and light technology, applied in the field of light printing paper and its preparation, can solve the problems of low smoothness, high roughness of light printing paper, large difference between two sides, etc. performance, reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

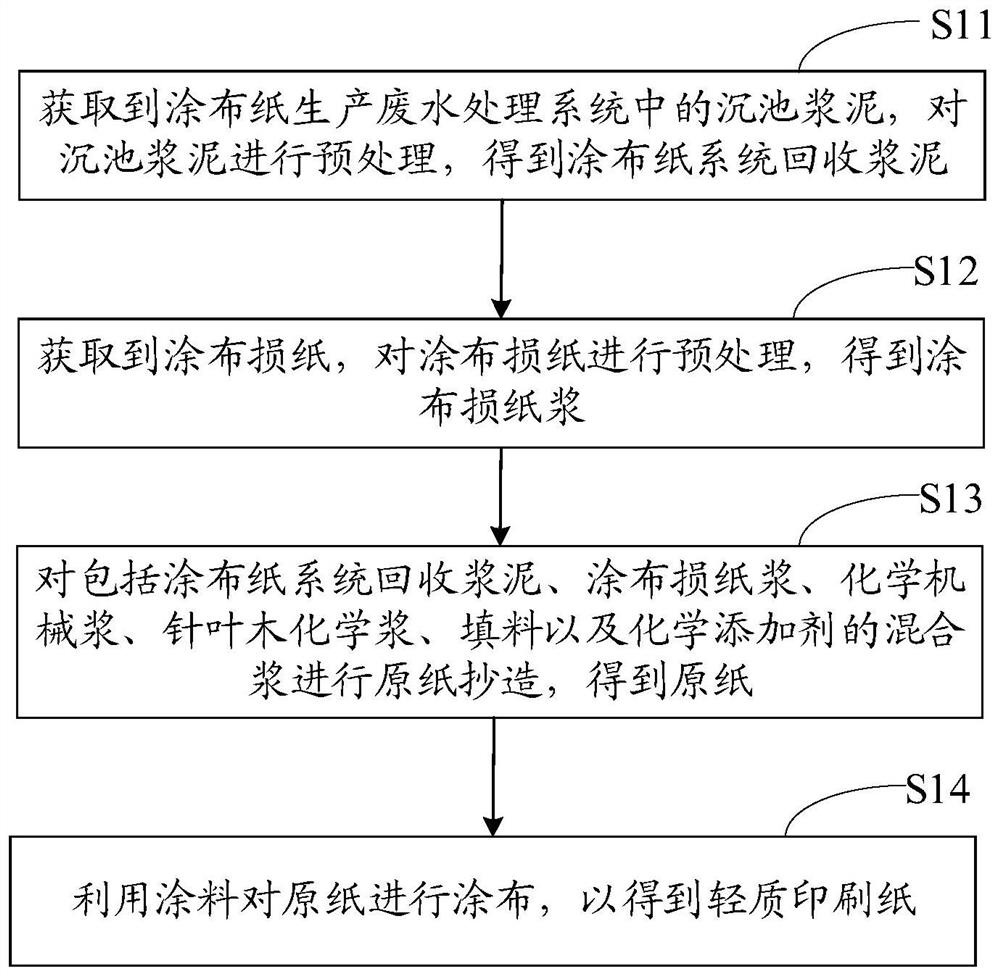

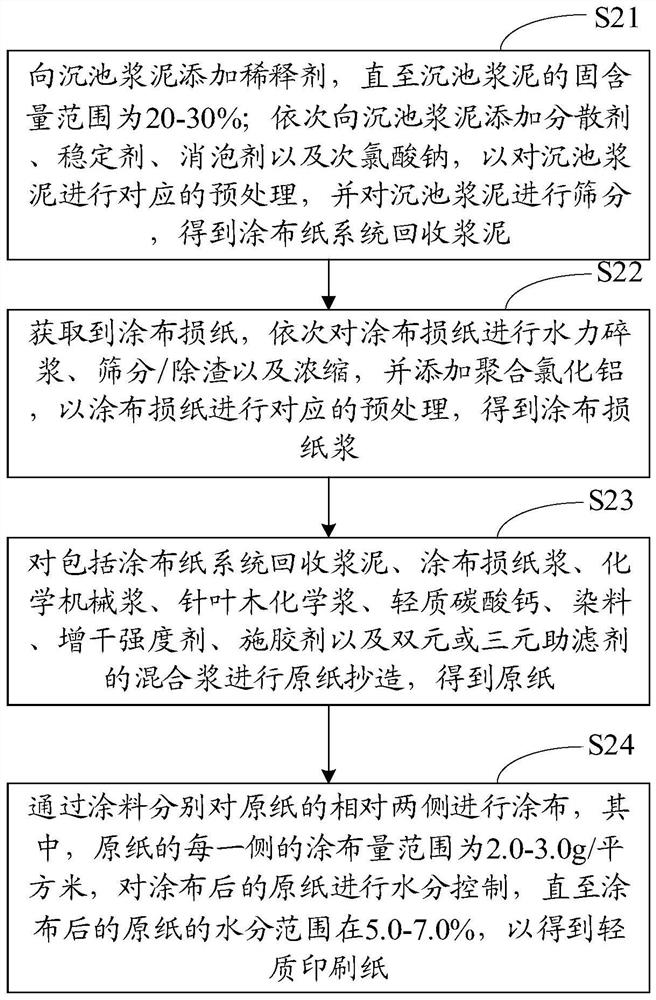

[0021] see figure 1 , figure 1 It is a schematic flow diagram of an embodiment of the preparation method of light printing paper of the present invention, and the preparation method of light printing paper of this embodiment comprises the following steps:

[0022] Step S11: Obtain the sedimentation tank sludge in the coated paper production wastewater treatment system, pretreat the sedimentation tank sludge, and obtain recycled sludge from the coated paper system.

[0023] In the wastewater treatment system of coated paper production, the sludge from the settling tank is collected and pretreated to obtain the recycled slurry from the coated paper system.

[0024] Wherein, due to the particle size of the sedimentation tank slurry in the coated paper production wastewater treatment system is small, this step is by reclaiming the sedimentation tank slurry in the coated paper production wastewater treatment system, and the obtained coated paper system reclaims the slurry. Act as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com