Preparing method for paint rheolytic moisture holding regulator

A technology of adjusting agent and coating, applied in paper coating, coating, fiber raw material treatment, etc., can solve the problems that the performance of water retention modifier is not so ideal, it is not conducive to the coating stability of coatings, and the improvement of water retention performance of coatings is limited. Wide range of water retention value adjustment, reduced adhesive migration, improved printing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

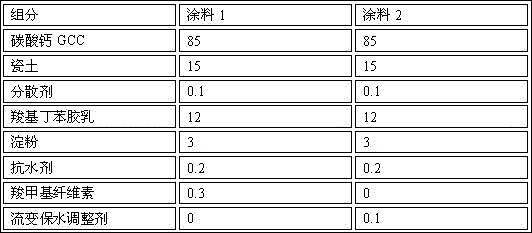

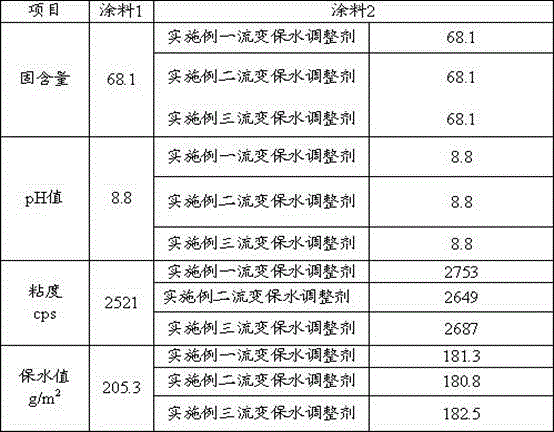

[0078] The salient features of the present invention will be described below from the specific preparation method of the paint rheology water retention modifier and the specific application of the paint rheology water retention modifier prepared by the preparation method of the present invention in coating.

[0079] 1. Preparation method of paint rheology water retention modifier

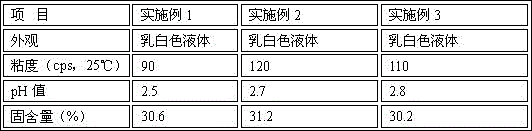

Embodiment 1

[0081] 100 parts of hydrophilic monomer + hydrophobic monomer

[0082] Surfactant 8 parts

[0083] Initiator 0.01 part

[0084] 0.01 parts of crosslinking agent

[0085] Emulsifier 0.1 parts

[0086] 250 parts of water

[0087] in:

[0088] Based on the weight of the monomer mixture as 100%, the hydrophilic monomer accounts for 30%, and the hydrophobic monomer accounts for 70%.

[0089] Hydrophilic monomer: acrylic acid: methacrylic acid: itaconic acid is 5:4:1;

[0090] Hydrophobic monomer: one or more of butyl acrylate, hydroxyethyl methacrylate, methyl methacrylate, 2-methyl methacrylate and 2-ethyl methacrylate;

[0091] Surfactant: modified functional monomer containing hydrophobic groups, behenyl alcohol polyoxyethylene ether methacrylate;

[0092] Initiator: ammonium persulfate

[0093] Cross-linking agent: diallyl phthalate

[0094] Emulsifier: sodium methacrylate hydroxypropyl sulfonate

[0095] Specifically include the following steps:

[0096] a. Add wate...

Embodiment 2

[0102] 100 parts of hydrophilic monomer + hydrophobic monomer

[0103] Surfactant 12 parts

[0104] Initiator 0.02 parts

[0105] 0.02 parts of crosslinking agent

[0106] 0.2 parts of emulsifier

[0107] 250 parts of water

[0108] in:

[0109] Based on the weight of the monomer mixture as 100%, the hydrophilic monomer accounts for 50%, and the hydrophobic monomer accounts for 50%.

[0110] Hydrophilic monomer: acrylic acid: methacrylic acid: itaconic acid is 5:4:1;

[0111] Hydrophobic monomer: one or more of butyl acrylate, hydroxyethyl methacrylate, methyl methacrylate, 2-methyl methacrylate and 2-ethyl methacrylate;

[0112] Surfactant: modified functional monomer containing hydrophobic groups, behenyl alcohol polyoxyethylene ether methacrylate;

[0113] Initiator: ammonium persulfate

[0114] Cross-linking agent: diallyl phthalate

[0115] Emulsifier: sodium methacrylate hydroxypropyl sulfonate

[0116] Specifically include the following steps:

[0117] a. Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com