Low engine oil level automatic alarming method

An automatic alarm and oil level technology, applied in the direction of lubricating indicating devices, lubricating parts, etc., can solve the problems of inability to monitor, engine damage, poor positioning accuracy, etc., and achieve accurate liquid level control, accurate liquid level detection, and fast response speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

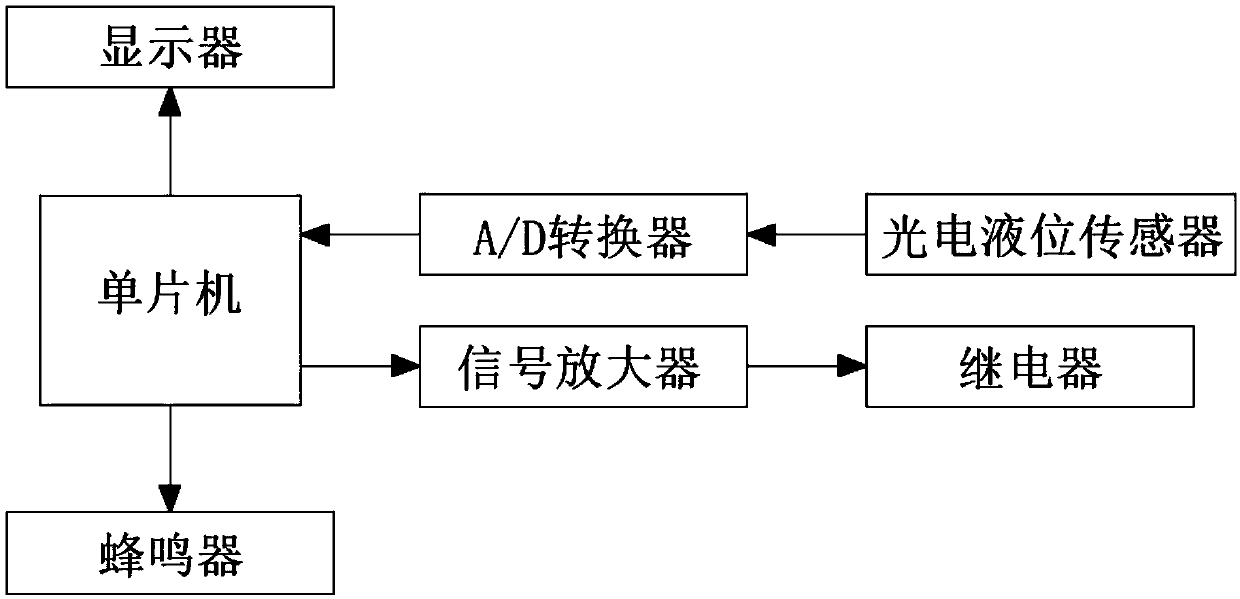

[0019] The present invention provides as figure 1 A low oil level automatic alarm method, including photoelectric liquid level sensor (model: m315253), A / D converter (model: AD7821), single-chip microcomputer (model: STC89C52), display, buzzer, signal Amplifier (model: TDA-02) and relay (model: JD104).

[0020] In this embodiment, the photoelectric liquid level sensor is used to realize the oil level measurement and control of the contact point machine by using the principle of reflection and refraction of light at the interface of two different media. The photoelectric liquid level sensor has nothing to do with other characteristics of the medium, including temperature, pressure, density, and electrical parameters. , so the liquid level detection is accurate, the repeatability is high, the response speed is fast, and the liquid level control is very precise. All the internal components of the photoelectric liquid level sensor have been resin-encapsulated, and there are no mec...

Embodiment 2

[0022] see figure 1 , the hardware part of the method includes a single-chip microcomputer main control module, a display, a buzzer, a power supply circuit, a signal acquisition circuit and a control circuit. This implementation is by setting the hardware part, which is a prerequisite for the realization of the low oil level automatic alarm.

Embodiment 3

[0024] see figure 1 , a photoelectric liquid level sensor, an A / D converter and a single-chip microcomputer form a signal acquisition circuit, and a single-chip microcomputer, a display, a buzzer, a signal amplifier and a relay form a control circuit. The engine oil level signal is sent to the single-chip microcomputer, and by setting the control circuit, the single-chip microcomputer sends commands to the display, buzzer and relay to realize control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com