Method for researching phase transition of a sample under high pressure

A sample and high-pressure technology, which is applied in the field of material research, can solve the problems that affect the heating efficiency of the device, optical resolution, poor achromatic lens effect, parameter optimization limitations, etc., and achieve the effect of small chromatic aberration, accurate determination, and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

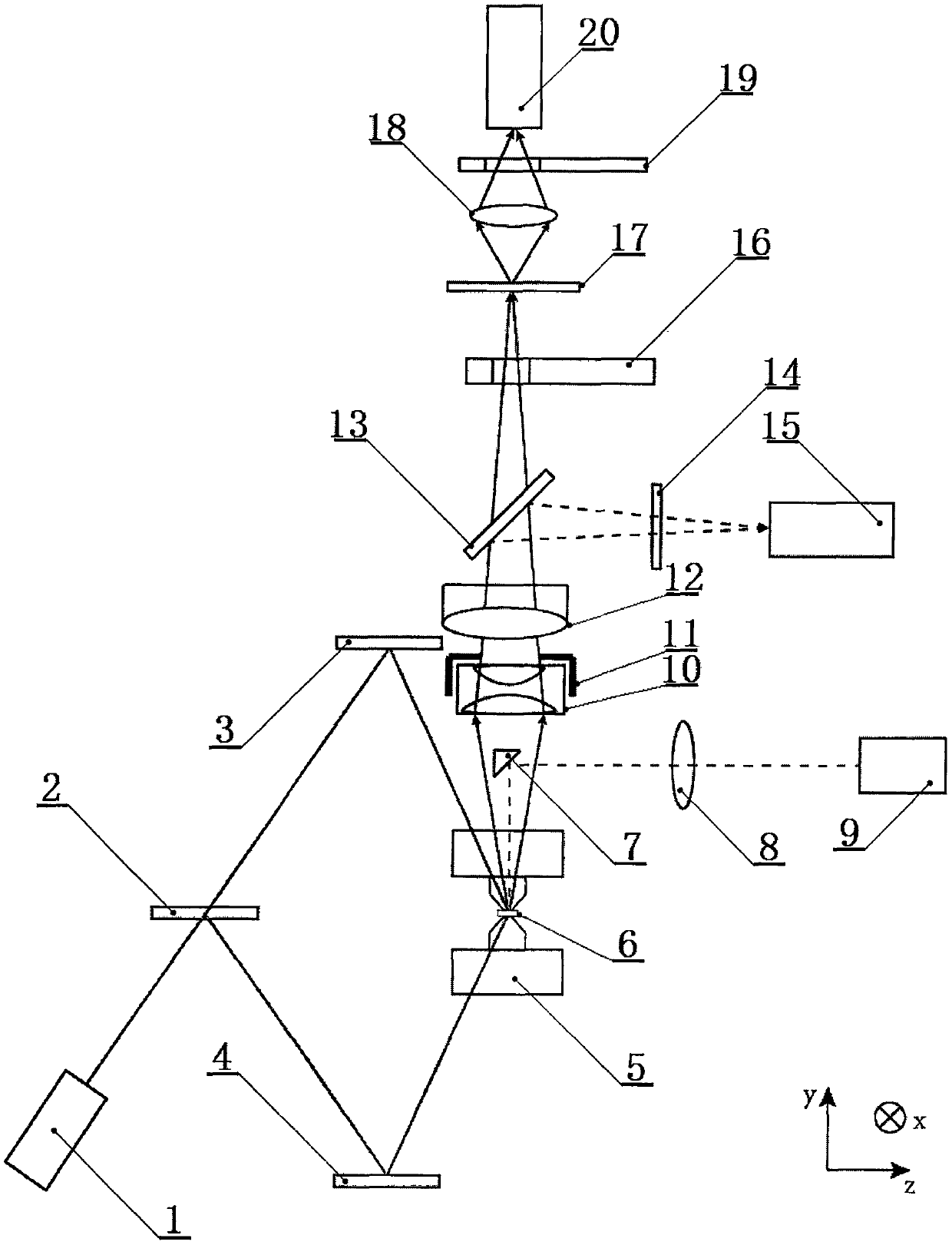

[0031] Such as figure 1 It is a schematic diagram of the present invention, including laser I (1), beam splitter I (2), mirror I (3), mirror II (4), sapphire anvil (5), sample (6), prism (7) , lens I (8), laser II (9), dephaser lens group (10), aperture (11), objective lens (12), beam splitter II (13), filter (14), video camera (15), Chopper (16), aperture diaphragm (17), lens II (18), optical filter group (19) and detector (20), the laser light that laser device I (1) emits is heating laser, laser device II (9) The emitted laser is an imaging laser, and the incident optical path of the heating laser, the incident optical path of the imaging laser, the thermal radiation path and the visible light path emitted by the sample, xyz is a three-dimensional Cartesian coordinate system; the sapphire anvil (5) includes the upper top Anvil and lower anvil, sample (6) is located between said upper anvil and lower anvil, sample (6) is a circle with a typical size of three millimeters in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com