A low-voltage high-current servo driver

A technology of servo drive and high current, which is applied in the control of electromechanical brakes, motor generator control, control of electromechanical transmission devices, etc. It can solve the problems of complicated and cumbersome debugging process and inconvenience for users, and achieve the effect of simplifying the debugging process and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described below in conjunction with accompanying drawing.

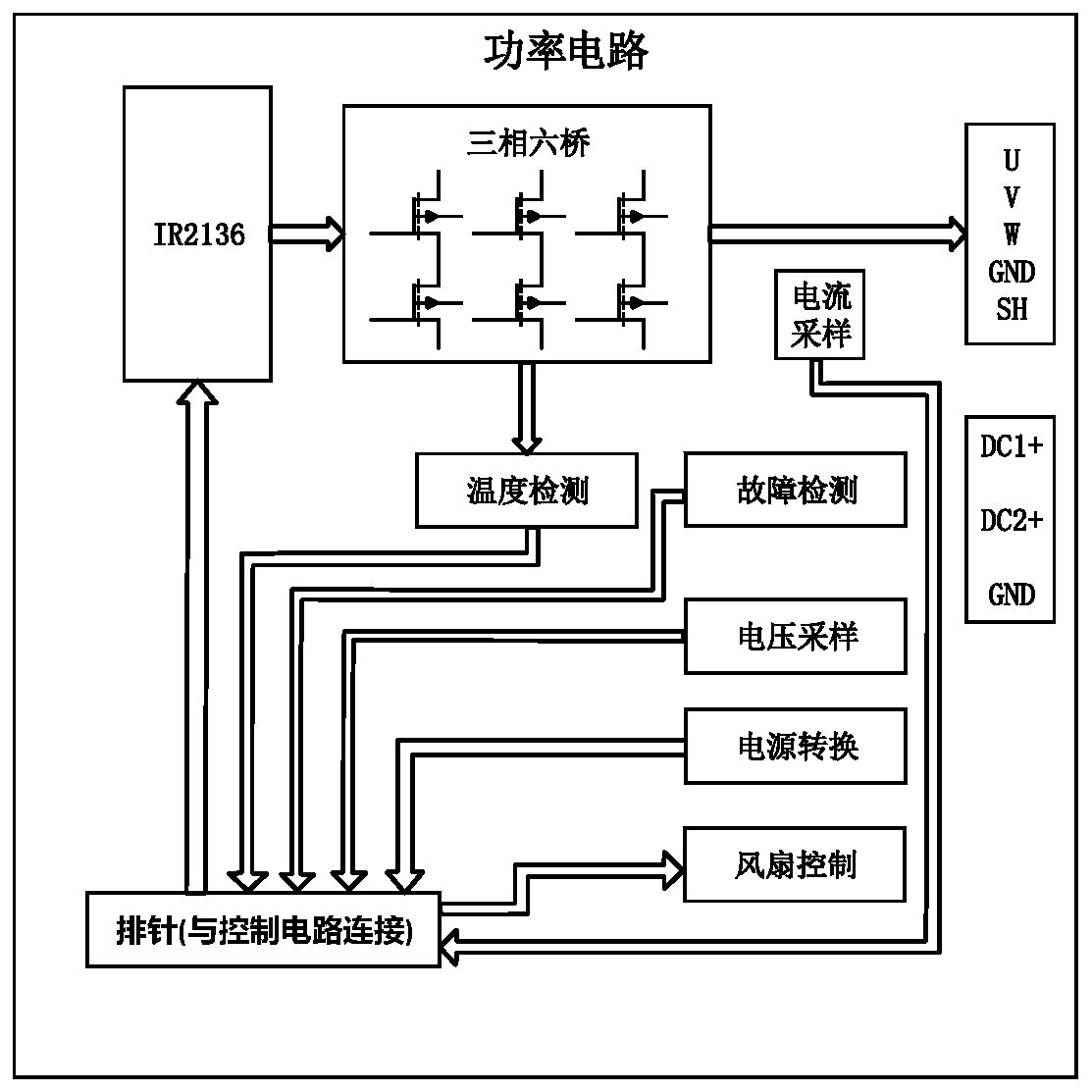

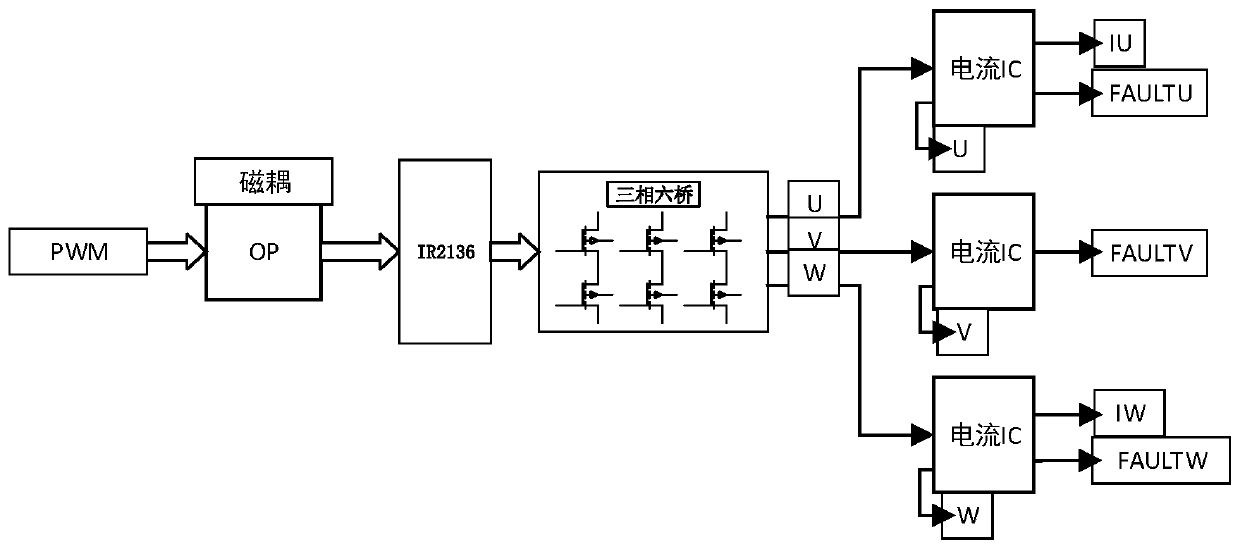

[0079] The low-voltage, high-current servo driver provided by the present invention adopts the FOC control algorithm, and the rated output phase current amplitude reaches 50A. The low-voltage, high-current servo driver includes a control circuit, a power circuit, and control software.

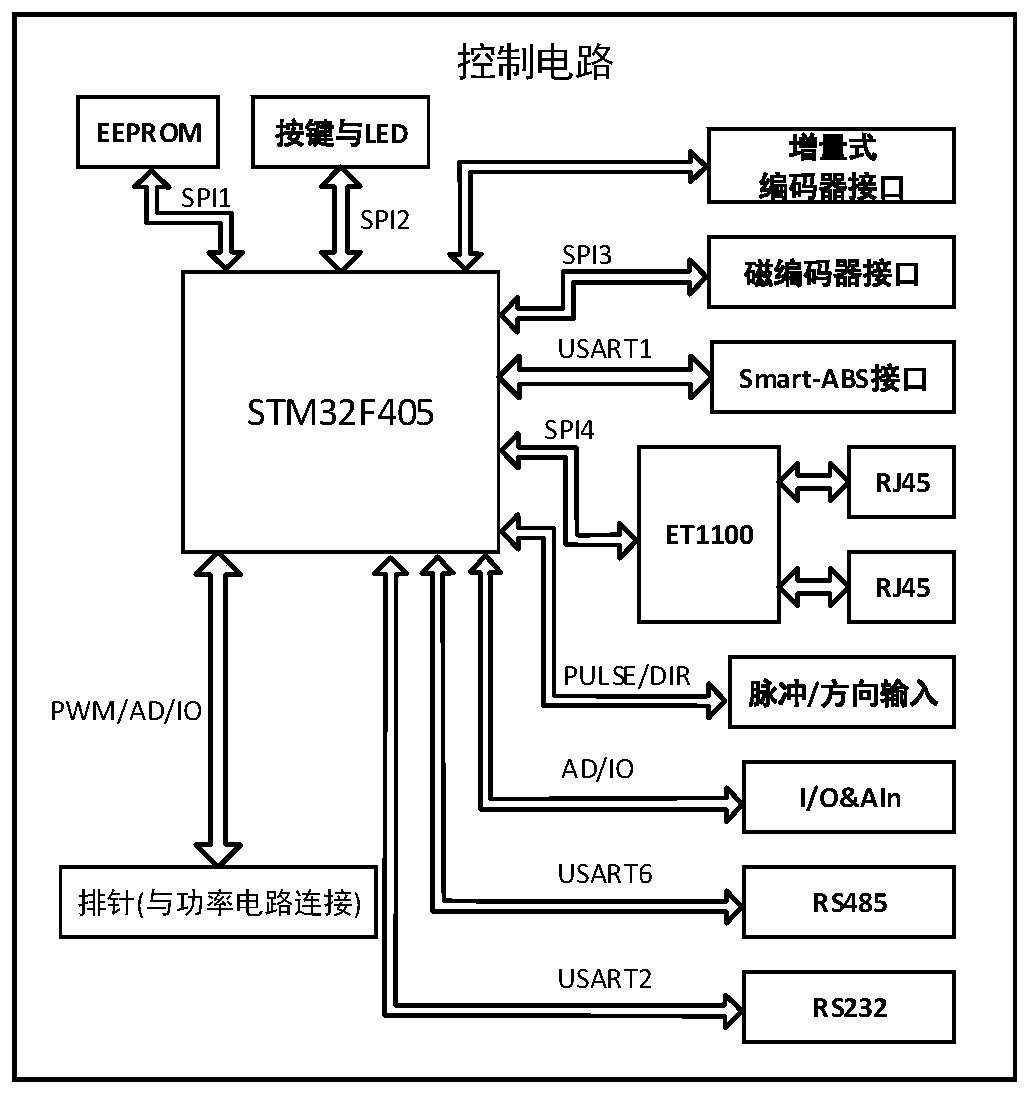

[0080] 1. Control circuit

[0081] The control circuit includes the main control CPU, parameter storage module, EtherCAT bus communication module, four-way SPI communication module, multiple communication interfaces, pulse / direction input interface, two-way isolated digital input and two-way isolated digital output (corresponding to attached figure 1 Medium I / O&AIn);

[0082] The main control CPU adopts STM32F405; the main control CPU provides two current sampling data input channels for the motor, and simultaneously collects the U-phase and W-phase current of the motor as the feedback of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com