Ecological culture technology for seawater industrial workshop

An ecological breeding and workshop technology, applied in fish farming, seaweed cultivation, climate change adaptation, etc., can solve the problems of low utilization rate of water resources and feed nutrients, self-pollution, etc., so as to reduce the cost of breeding, improve the utilization rate, improve The effect of breeding benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

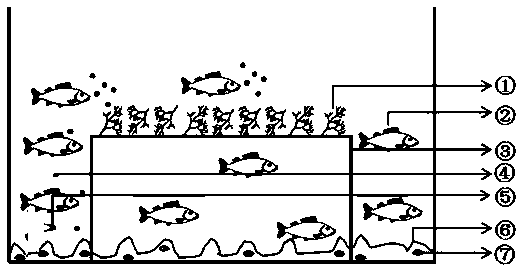

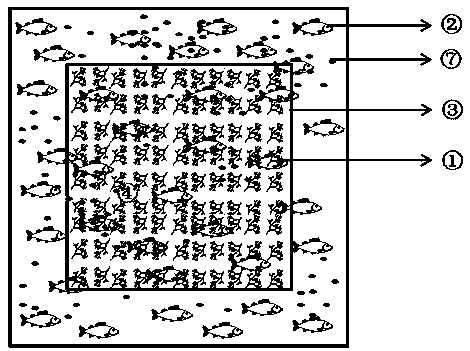

[0032] In this embodiment, a seawater factory workshop ecological breeding technology is selected, a typical factory workshop cement breeding pond 6m×6m×1m is selected for transformation, the pond depth is 0.8m, and a 4m×4m×0.4m PVC is built in the culture pond Shelves, the weights of various organisms are: moiré gentian grouper (average weight of individual 300g) 300kg, macroalgae selected Gracilaria platyphylla 25kg, benthic shellfish selected four-cornered clam 15kg, benthic diatom selected core Algae stock solution (10 6 Pieces / ml) 1500ml.

[0033] The key points of the ecological breeding technology in this embodiment:

[0034] 1) Workshop transformation: The roof of the large shed in the breeding workshop is transformed into a sunshine board, and the light transmission of the sunshine board needs to be adjusted according to the season, so that the strongest light intensity on the breeding water surface is between 2500~3000lx; the breeding pond is built 4m×4m×0.4 The mPVC she...

Embodiment 2

[0040] In this example, the ecological farming technology of the seawater factory workshop is to choose a typical factory workshop farming cement pond 6m×6m×1m, the pond water depth is 0.8m, and the transformation is carried out, and a 4m×4m×0.4m PVC shelf is built in the culture pond. The weight of each kind of creatures put into the rack is: 300kg of Moiré gentian grouper with an average weight of 400g, about 750 pieces, 25kg of macroalgae selected from Rhodophyta, 15kg of benthic shellfish from Philippine clam, and benthic silica Algae selection costal alga stock solution (10 6 Pieces / ml) 1500ml.

[0041] The key points of the ecological breeding technology in this embodiment:

[0042] 1) Workshop transformation: The roof of the large shed in the breeding workshop is transformed into a sunshine board, and the light transmission of the sunshine board needs to be adjusted according to the season, so that the strongest light intensity on the breeding water surface is between 2500~3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com