Method for preparing granular meat sausages

A meat granulation and enema technology, which is applied in the field of meat granulation enema preparation, can solve the problems that it is difficult to meet the special requirements of enema products, the shape and contents of minced meat fillings are single, and the development of the meat product industry is affected. , Guarantee the marinating effect and improve the chewing effect of the enema

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

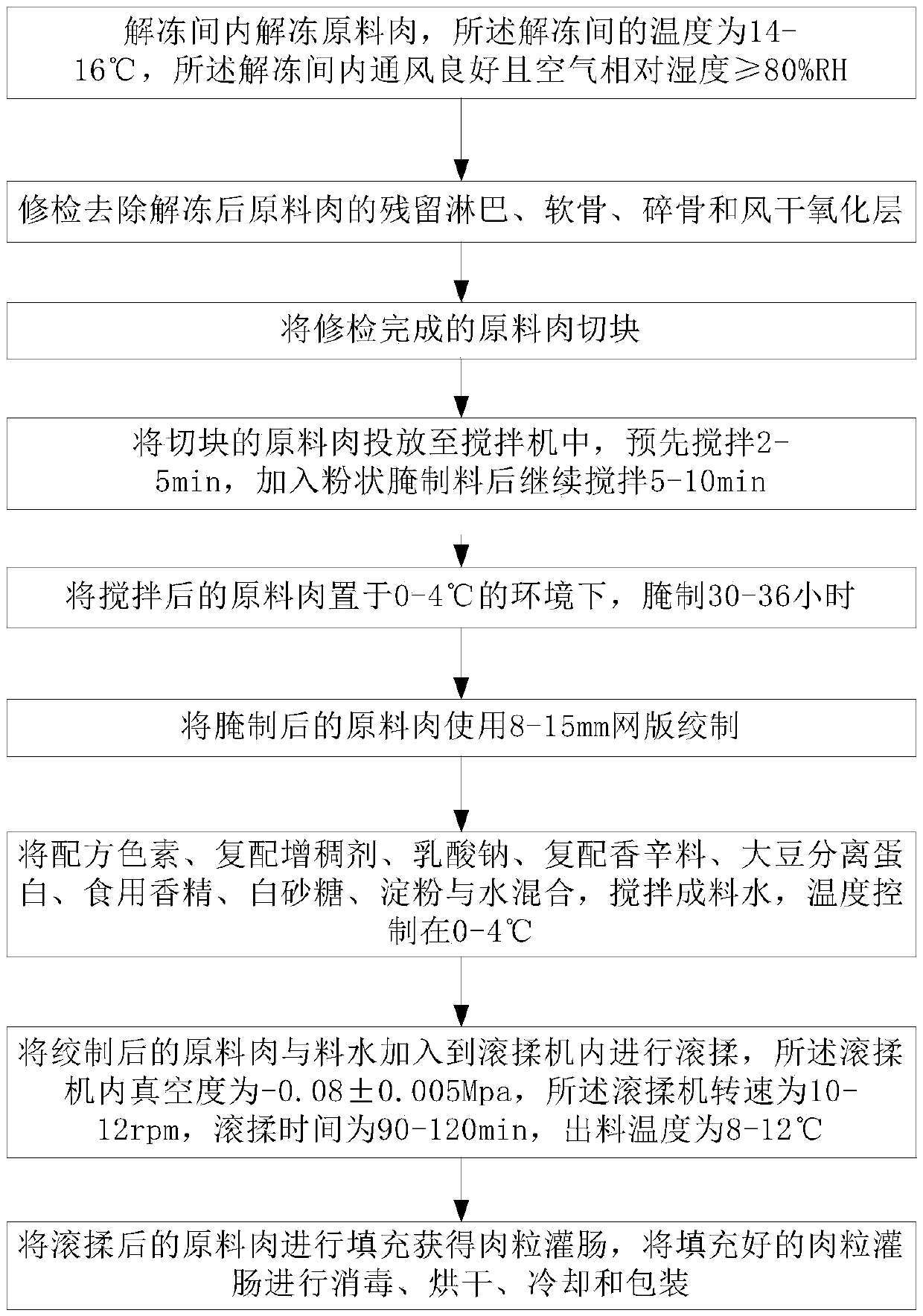

[0051] The preparation method of the meat grain enema provided in this embodiment, the method comprises:

[0052] Thaw the raw meat in the thawing room, the temperature of the thawing room is 14°C, the ventilation in the thawing room is good and the relative air humidity is 85%RH;

[0053] Repair and remove the residual lymph, cartilage, broken bone and air-dried oxide layer of raw meat after thawing;

[0054] Cut the overhauled raw meat into cubes of 3cm*3cm*3cm;

[0055] Put the diced raw meat into the blender, stir for 2 minutes in advance, add the powdered marinade and continue stirring for 8 minutes;

[0056] Place the stirred raw meat in an environment of 2°C and marinate for 32 hours;

[0057] The marinated raw meat is twisted with an 8mm screen;

[0058] Mix formula pigment, compound thickener, sodium lactate, compound spices, soybean protein isolate, food flavor, white sugar, starch and water, stir to form feed water, and control the temperature at 0°C;

[0059] T...

Embodiment 2

[0063] The preparation method of the meat grain enema provided in this embodiment, the method comprises:

[0064] Thaw the raw meat in the thawing room, the temperature of the thawing room is 15°C, the ventilation in the thawing room is good and the relative air humidity is 80%RH;

[0065] Repair and remove the residual lymph, cartilage, broken bone and air-dried oxide layer of raw meat after thawing;

[0066] Cut the overhauled raw meat into cubes of 4cm*4cm*4cm;

[0067] Put the diced raw meat into the blender, pre-stir for 5 minutes, add the powdered marinade and continue to stir for 10 min. The powdered marinade includes edible salt, phosphate and sodium D-isoascorbate;

[0068] Place the stirred raw meat at 4°C and marinate for 30 hours;

[0069] Use a 10mm screen to grind the marinated raw meat;

[0070] Mix formula pigment, compound thickener, sodium lactate, compound spices, soybean protein isolate, food flavor, white sugar, starch and water, stir to form feed water...

Embodiment 3

[0075] The preparation method of the meat grain enema provided in this embodiment, the method comprises:

[0076] Thaw the raw meat in the thawing room, the temperature of the thawing room is 16°C, the ventilation in the thawing room is good and the relative air humidity is 80%RH;

[0077] Repair and remove the residual lymph, cartilage, broken bone and air-dried oxide layer of raw meat after thawing;

[0078] Cut the finished raw meat into cubes of 5cm*5cm*5cm;

[0079] Put the diced raw meat into the blender, pre-stir for 3 minutes, add the powdered marinade and continue to stir for 5 minutes. The powdered marinade includes edible salt, phosphate and sodium D-isoascorbate;

[0080] Place the stirred raw meat in an environment of 1°C and marinate for 36 hours;

[0081] Grind the marinated raw meat with 12 screens;

[0082] Mix the formula pigment, compound thickener, sodium lactate, compound spices, soybean protein isolate, food flavor, white sugar, starch and water, stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com