A Rotary Top Safety Isolation Device

A rotary top and safety isolation technology, applied in the direction of tailstock/top, maintenance and safety accessories, manufacturing tools, etc., can solve problems such as combustion or explosion hazards, serious fire accidents, collision between tools and steel rotary tops, etc., to achieve structural Simple, fast assembly and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below through specific embodiments and accompanying drawings.

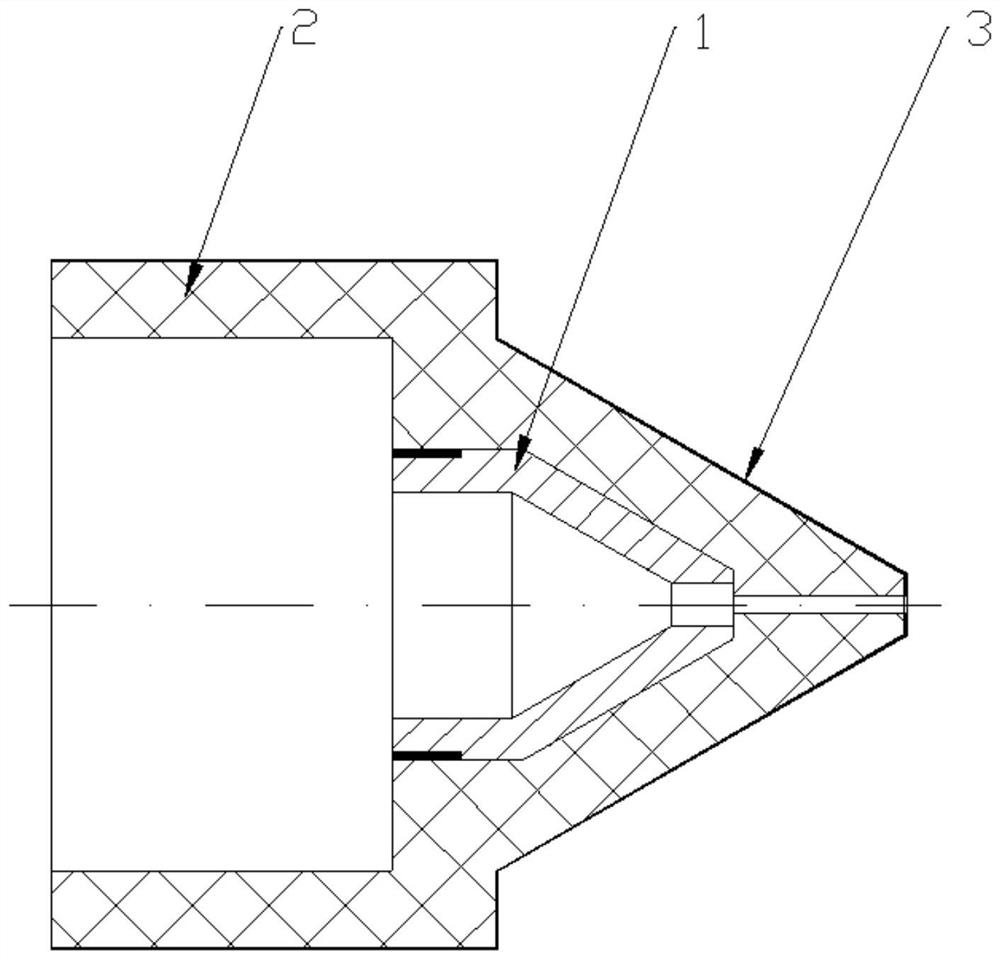

[0016] Such as figure 1 , in the rotary top safety isolation device for solid propellant charge turning, the guide cone 1 is made of beryllium bronze with high strength and good wear resistance, and the tolerance zone of the cylindrical hole on the inner surface is designed to be H7, which ensures that The rotating head is closely matched, and has the functions of installation, fixing and guiding. The tapered hole on the inner surface is designed to have a busbar angle of 60°. The inner surface of the guide cone 1 is polished to a roughness of 1.6-3.2 to ensure close connection with the conical rotary head of the rotary top and to realize the positioning of the tapered hole. A small hole Φ5.0mm is processed at the right end of the tapered hole to avoid interference between the rotary head and the tapered hole. The left end of the outer surface of the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com