MIG-TIG composite material adding device

A water-cooling device and industrial robot technology, applied in the field of additive manufacturing, can solve the problems of different accuracy and efficiency of additive methods, uneven surface, low arc precision, etc., to control interlayer temperature, improve additive quality, and increase The effect of material accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

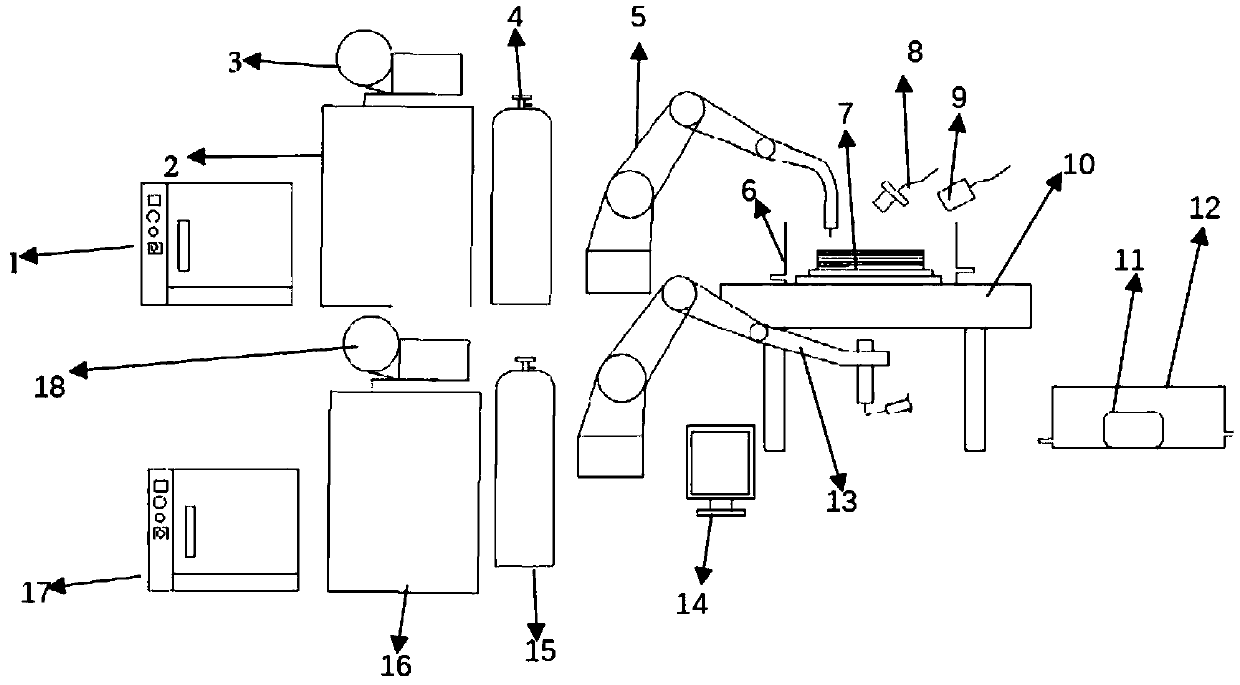

[0025] like figure 1 As shown, the MIG-TIG composite additive device consists of industrial robot 1, robot control cabinet 1, welding power supply 1, wire feeder 1, MIG welding torch, protective gas cylinder 1, industrial robot 2, robot control cabinet 2, welding power supply 2, Wire feeder 2, TIG welding gun, protective gas cylinder 2, CCD camera, workbench, infrared thermometer, substrate water cooling device, computer;

[0026] Industrial robot 1, robot control cabinet 1, welding power supply 1, wire feeder 1, MIG welding gun, protective gas cylinder 1 to form a MIG additive robot; industrial robot 2, robot control cabinet 2, welding power supply 2, wire feeder 2, TIG A TIG additive robot composed of a welding torch and a protective gas cylinder; the MIG welding torch and the TIG welding torch are fixed on the industrial robot 1 and the industrial robot 2 through flexible clamps.

[0027] Industrial robot 1 and industrial robot 2 are ABB articulated arm robots with the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com