Combined machining system and method of ultrasonic vibration assisted grinding and magnetic polishing

A technology of ultrasonic vibration and magnetic polishing, which is applied in the field of advanced manufacturing, can solve the problems of multi-component composite processing with a very small number of processing technologies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described in detail below through specific embodiments and accompanying drawings.

[0023] Now take the transformation of the vertical-axis rectangular table precision surface grinder into a composite processing system of ultrasonic vibration-assisted grinding and magnetic polishing to realize efficient and precise processing of silicon carbide ceramics as an example. It includes the following steps:

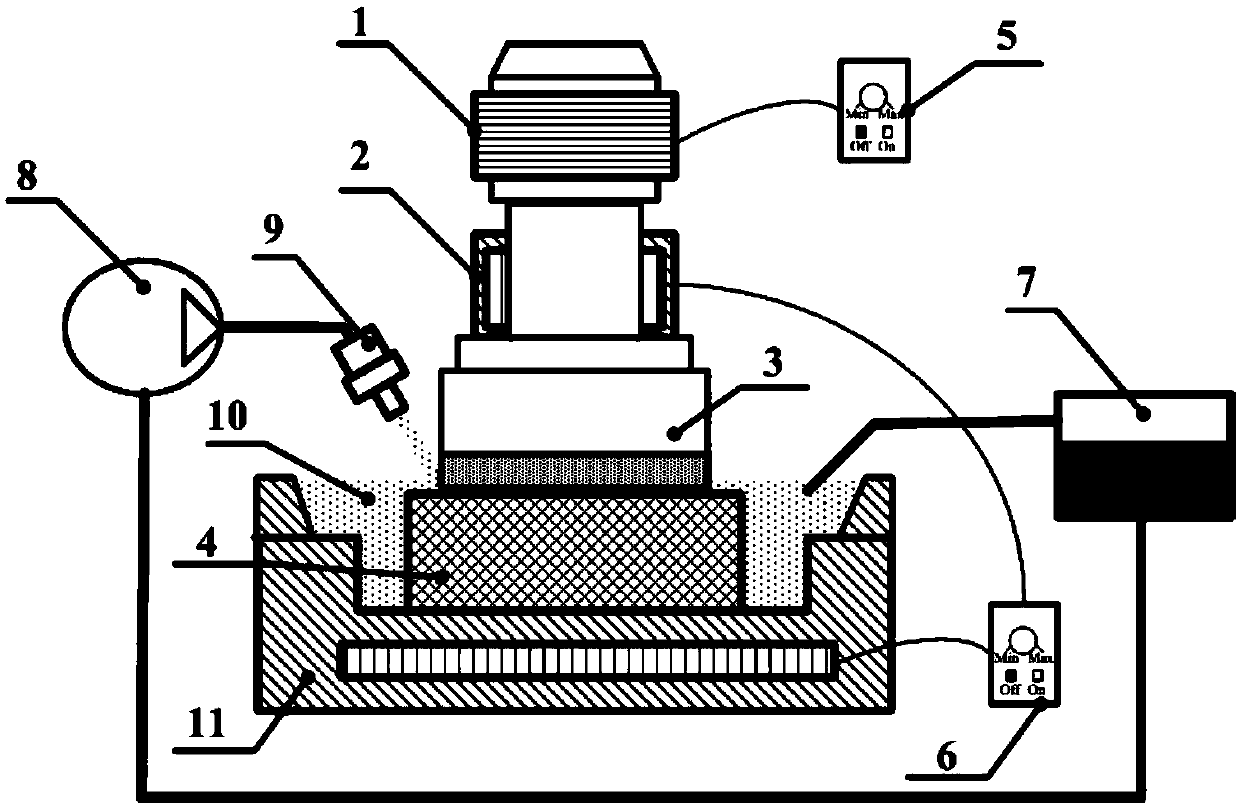

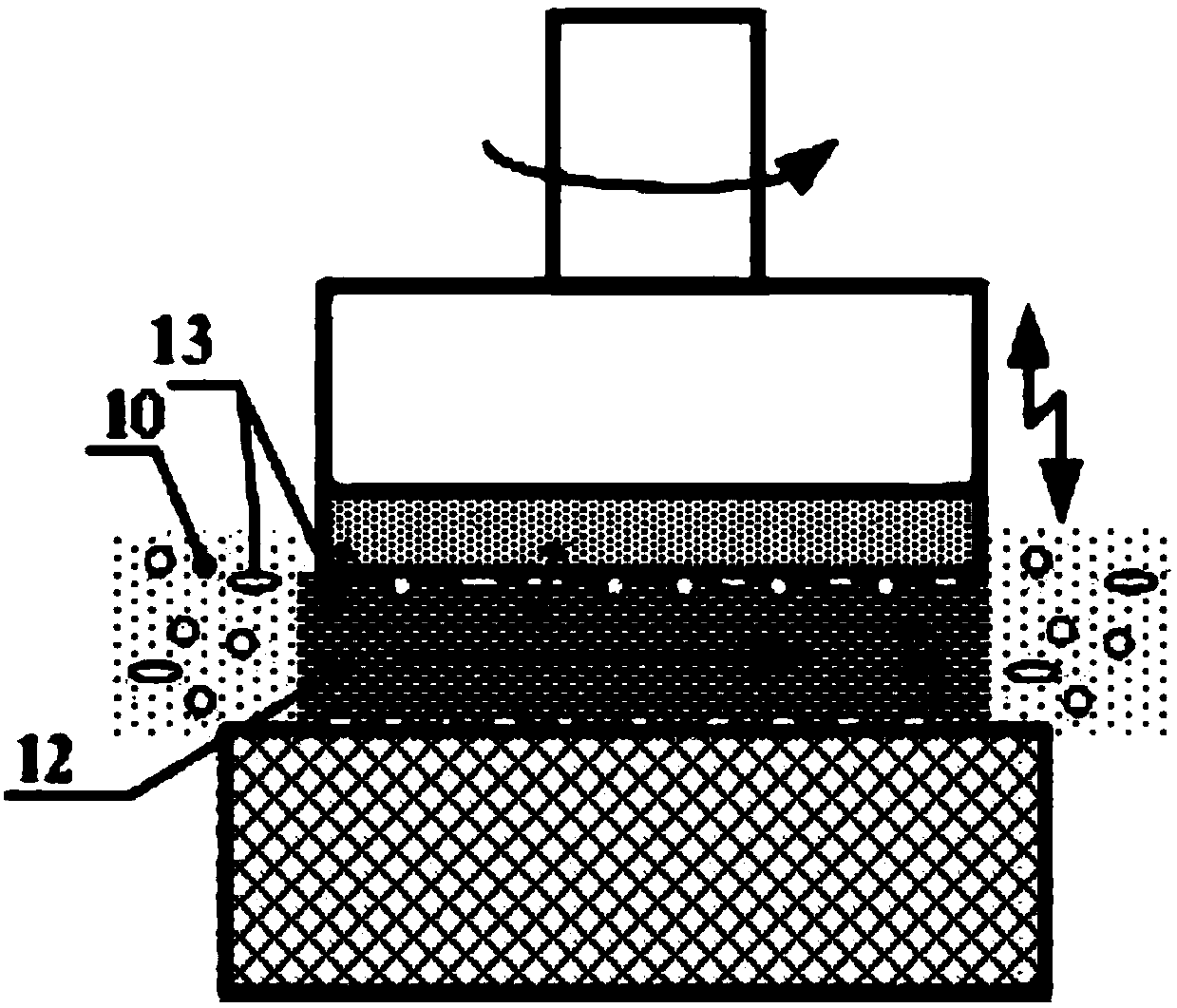

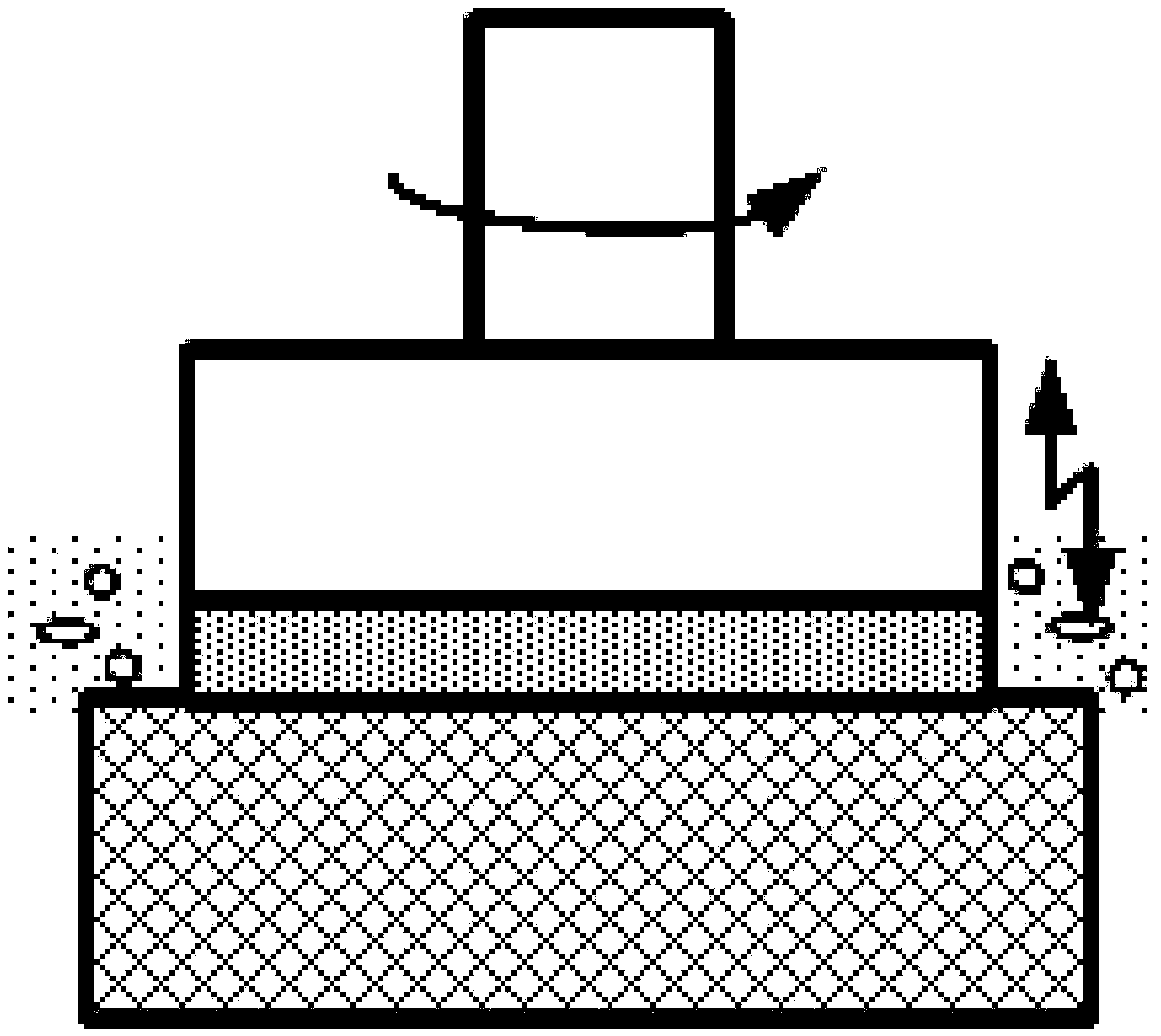

[0024] Step 1: Based on the vertical axis rectangular platform precision surface grinder, establish the ultrasonic vibration assisted grinding-magnetic polishing composite processing system, as shown in the attached figure 1 shown. The ultrasonic vibration generating device 1 and the electromagnetic field generating device 2 are installed on the main shaft where the diamond grinding wheel 3 is fixed, the first controller 5 can adjust the ultrasonic vibration frequency, and the second controller 6 can adjust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com