Ultra-high speed injection molding machine with cooling nozzle

A cooling nozzle and ultra-high-speed technology, applied in the field of injection molding machinery, can solve the problems of reducing the temperature of the injection molding melt, overheating and scorching of materials, and excessively fast injection speed, so as to achieve the effects of ensuring quality, preventing scorching, and being easy to maintain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

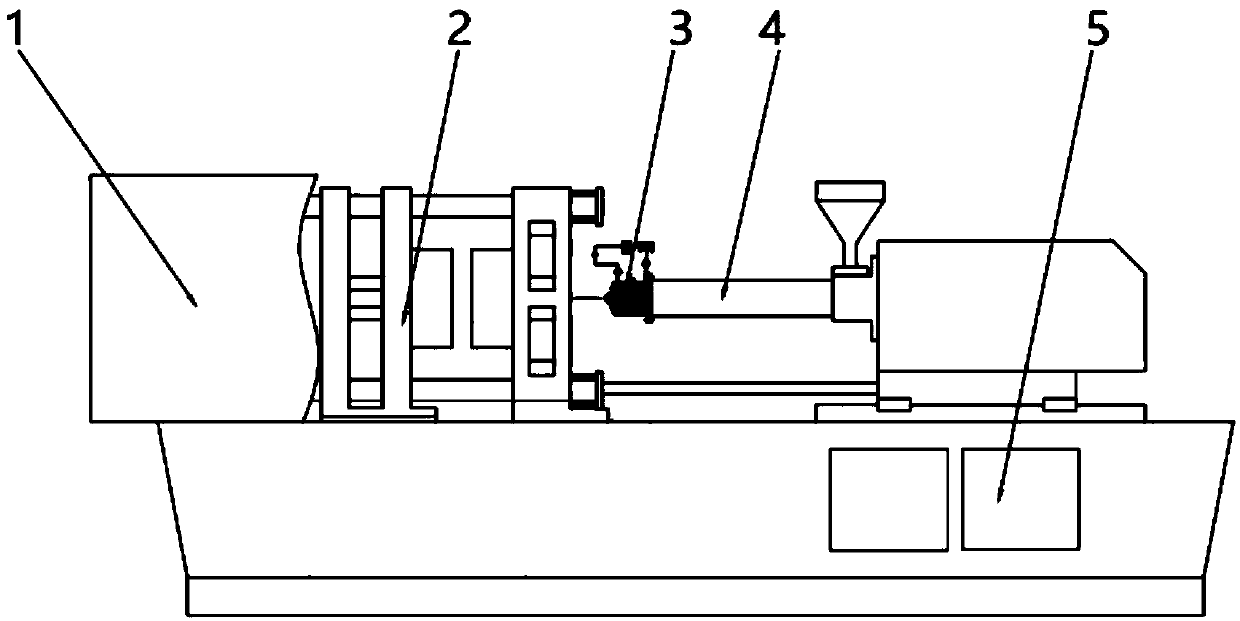

[0016] The present invention is an ultra-high-speed injection molding machine with a cooling nozzle, such as figure 1 As shown, it is mainly composed of hydraulic part 1, mold clamping part 2, injection nozzle 3, injection part 4 and electrical part 5, etc. The injection nozzle 3 mainly includes an internal cooling part, an external circulation part and a temperature compensation part. The connection mode of the injection nozzle 3 is the same as that of the conventional nozzle, that is, the position of the nozzle end and the barrel at the front end of the injection screw is connected by threads.

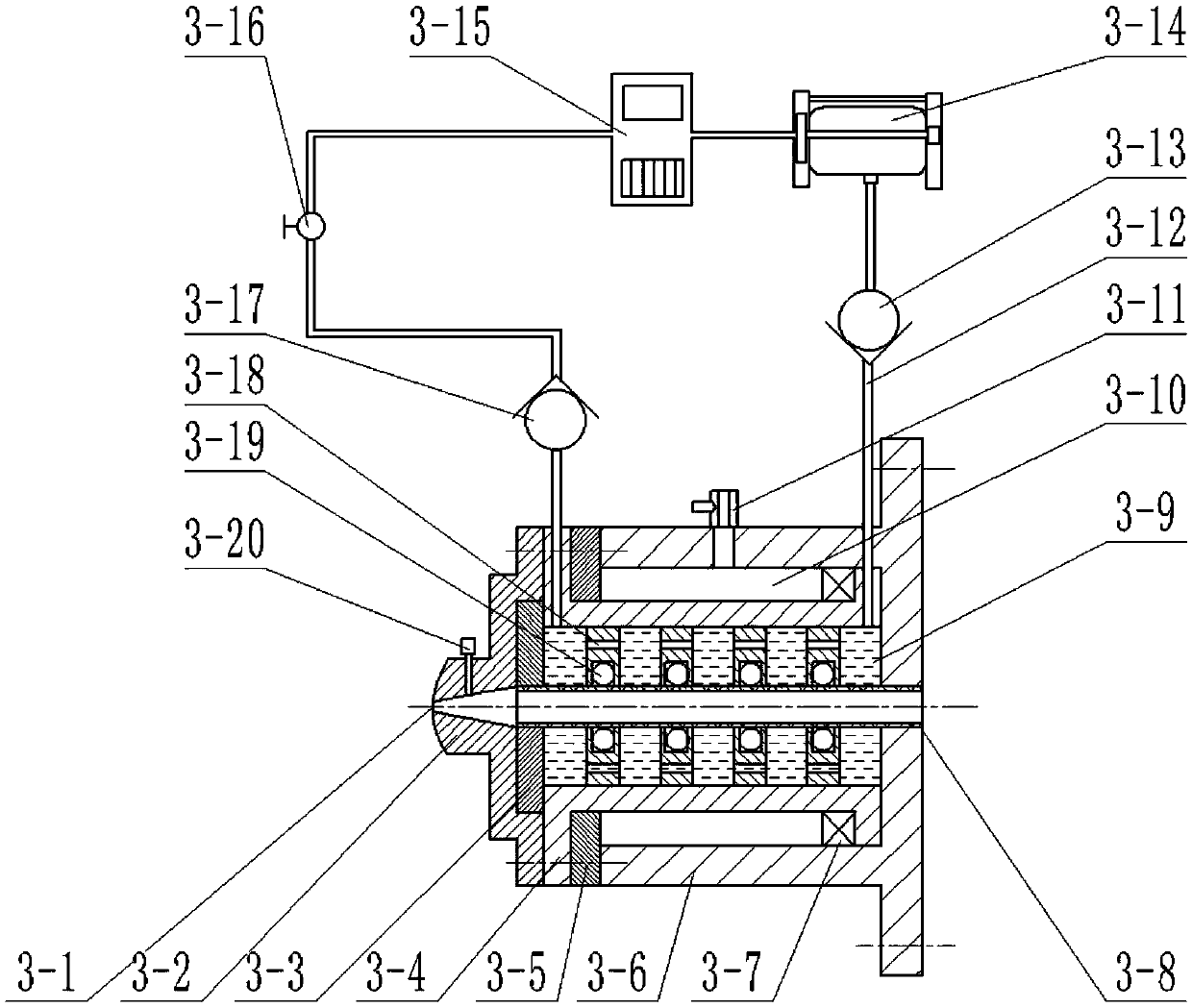

[0017] The present invention is an ultra-high-speed injection molding machine with a cooling nozzle, and the internal cooling part of the injection nozzle 3 is as follows: figure 2 As shown, it mainly consists of nozzle head 3-1, nozzle housing 3-2, front sealing ring 3-3, heat insulating inner cylinder 3-4, rear sealing ring 3-5, heat insulating outer cylinder 3-6, It consists of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com