Microbial mineralized fiber micro reinforcement concrete material facing 3D printing and preparation method thereof

A technology of micro-reinforced concrete and 3D printing, applied in the direction of additive processing, etc., can solve the problem of limited lifting range, achieve the effect of improving performance, improving strength and ductility, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

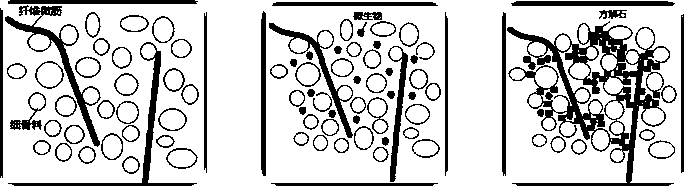

[0032] A 3D printing-oriented microbial mineralized fiber micro-reinforced concrete material (see figure 1), which is mainly composed of the following raw materials in parts by weight: 100 parts of Portland cement, 30 parts of fly ash, 150 parts of quartz sand with a particle size of 0.15 mm to 4.75 mm, 2 parts of polypropylene fiber with a length of 9 mm, early strength 2.5 parts of sodium sulfate, 4.0 parts of sodium aluminate quick-setting agent, 30 parts of water, 30 parts of microbial bacteria liquid. The microbial bacterial liquid is composed of bacillus pasteurian liquid and nutrient solution containing urea and calcium chloride, wherein the concentration of bacillus pasteurian bacterial liquid is OD600 value of 1.2, urea 60 g / L, calcium chloride 111 g / L.

[0033] The preparation method of the above-mentioned microbial mineralized fiber micro-reinforced concrete material oriented to 3D printing is specifically: put Portland cement, fly ash, sand, microbial bacterial li...

Embodiment 2

[0035] A microbial mineralized fiber micro-reinforced concrete material for 3D printing, which is mainly composed of the following raw materials in parts by weight: 100 parts of Portland cement, 20 parts of fly ash, and 100 parts of river sand with a particle size of 0.15 mm to 4.75 mm 1 part of carbon fiber with a length of 12 mm, 4 parts of early strength agent sodium sulfate, 5.0 parts of quick-setting agent sodium aluminate aluminate, 20 parts of water, and 40 parts of microbial bacterial liquid. The microbial bacterial liquid is composed of bacillus pasteurian bacterial liquid and nutrient solution containing urea and calcium chloride, wherein the concentration of bacillus pasteurian bacterial liquid is OD600 value of 0.8, urea 45g / L, calcium chloride 130 g / L.

[0036] Refer to Example 1 for the preparation method of the above 3D printing-oriented microbial mineralized fiber micro-reinforced concrete material.

Embodiment 3

[0038] A 3D printing-oriented microbial mineralized fiber micro-reinforced concrete material, which is mainly composed of the following raw materials in parts by weight: 100 parts of Portland cement, 40 parts of fly ash, 250 parts of quartz sand with a particle size of 0.15 mm to 4.75 mm 4 parts of glass fiber with a length of 6 mm, 1.5 parts of early strength agent sodium sulfate, 3.0 parts of quick-setting agent sodium aluminate aluminate, 40 parts of water, and 20 parts of microbial bacterial liquid. Described microbial bacterial liquid is made up of bacillus pasteurian bacterial liquid, and the nutrient solution containing urea and calcium chloride, wherein, the concentration of bacillus pasteurian bacterial liquid is that OD600 value is at 1.0, urea 75g / L, calcium chloride 90g / L.

[0039] Refer to Example 1 for the preparation method of the above 3D printing-oriented microbial mineralized fiber micro-reinforced concrete material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com