A regenerated silicon carbide al 2 o 3 -sic-c iron ditch castable and preparation method thereof

A technology of iron trench castables and silicon carbide, which is applied in the field of refractory materials, can solve the problems of high usage of SiC, waste of SiC resources, and large amount of waste, so as to improve anti-oxidation performance, save the use of raw materials, and achieve good anti-oxidation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

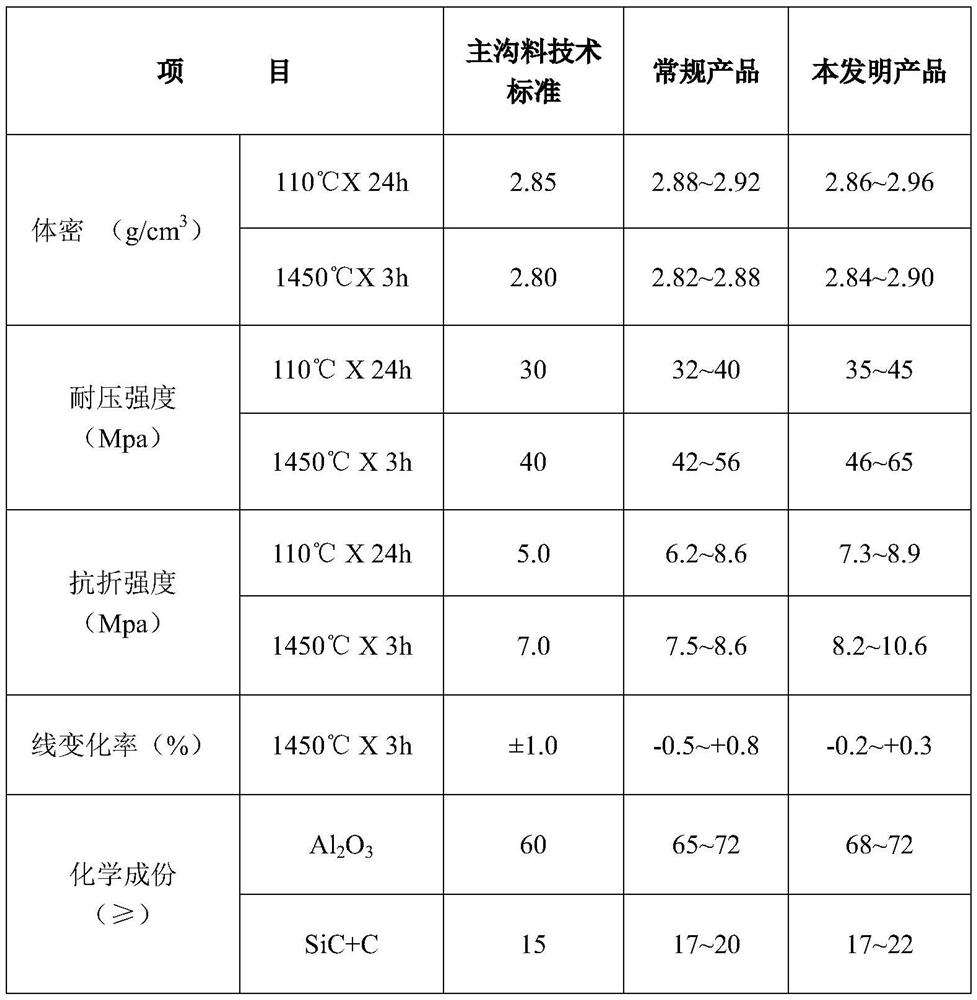

Image

Examples

Embodiment 1

[0030] A kind of regenerated silicon carbide Al 2 o 3 -SiC-C iron channel castable, which is prepared from the following raw materials by weight percentage: brown corundum is 62%, regenerated silicon carbide is 20%, active Al 2 o 3 Micropowder is 6%, silicon micropowder is 3%, carbon black is 2%, antioxidant is 2.5%, pure calcium aluminate cement is 3%, asphalt is 1.5%;

[0031] Add explosion-proof fibers accounting for 0.05% of the total amount of the above raw materials, water reducing agents accounting for 0.06% of the total amount of the above raw materials, and dispersants accounting for 0.08% of the total amount of the above raw materials;

[0032] Among the above raw materials:

[0033] The regenerated silicon carbide includes the following raw materials with different particle size distributions: 15% for 3-1mm, 35% for 1-0mm, and 50% for -200 mesh; the SiC content in the regenerated silicon carbide is 78%- 85%, Al 2 o 3 The content is 8-12%, Fe 2 o 3 ≤0.5%;

...

Embodiment 2

[0043] A kind of regenerated silicon carbide Al 2 o 3 -SiC-C iron channel castable, which is prepared from the following raw materials by weight percentage: brown corundum is 60%, regenerated silicon carbide is 20%, active Al 2 o 3 Micropowder is 5%, silicon micropowder is 3%, carbon black is 3%, antioxidant is 2.5%, pure calcium aluminate cement is 4%, asphalt is 2.5%;

[0044] Add explosion-proof fiber accounting for 0.08% of the total amount of raw materials, water reducing agent accounting for 0.08% of the total amount of raw materials and dispersant accounting for 0.08% of the total amount of raw materials.

[0045] Among the above raw materials:

[0046] The regenerated silicon carbide includes the following raw materials with different particle size distributions: 15% for 3-1mm, 35% for 1-0mm, and 50% for -200 mesh; the SiC content in the regenerated silicon carbide is 78%- 85%, Al 2 o 3 The content is 8-12%, Fe 2 o 3 ≤0.5%;

[0047] The content of C in the car...

Embodiment 3

[0056] A kind of regenerated silicon carbide Al 2 o 3 - SiC-C iron channel castable, which is prepared from the following raw materials by weight percentage: brown corundum is 60%, regenerated silicon carbide is 24%, active Al 2 o 3 Micropowder is 4%, silicon micropowder is 2%, carbon black is 3%, antioxidant is 2%, pure calcium aluminate cement is 3%, asphalt is 2%;

[0057] Add explosion-proof fiber accounting for 0.08% of the total amount of raw materials, water reducer accounting for 0.08% of the total amount of raw materials and dispersant accounting for 0.10% of the total amount of raw materials.

[0058] Among the above raw materials:

[0059] The regenerated silicon carbide includes the following raw materials with different particle size distributions: 20% for 3-1mm, 40% for 1-0mm, and 40% for -200 mesh; the SiC content in the regenerated silicon carbide is 78%- 85%, Al 2 o 3 The content is 8-12%, Fe 2 o 3 ≤0.5%;

[0060] The content of C in the carbon black ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com