A kind of annealing method of stainless steel strip

A stainless steel strip and annealing technology, which is applied in the field of stainless steel, can solve the problems of insufficient brightness, high production difficulty, and unsatisfactory mechanical properties of stainless steel strips, and achieve the effects of bright and high-grade appearance, good flatness, and shortened high-temperature annealing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

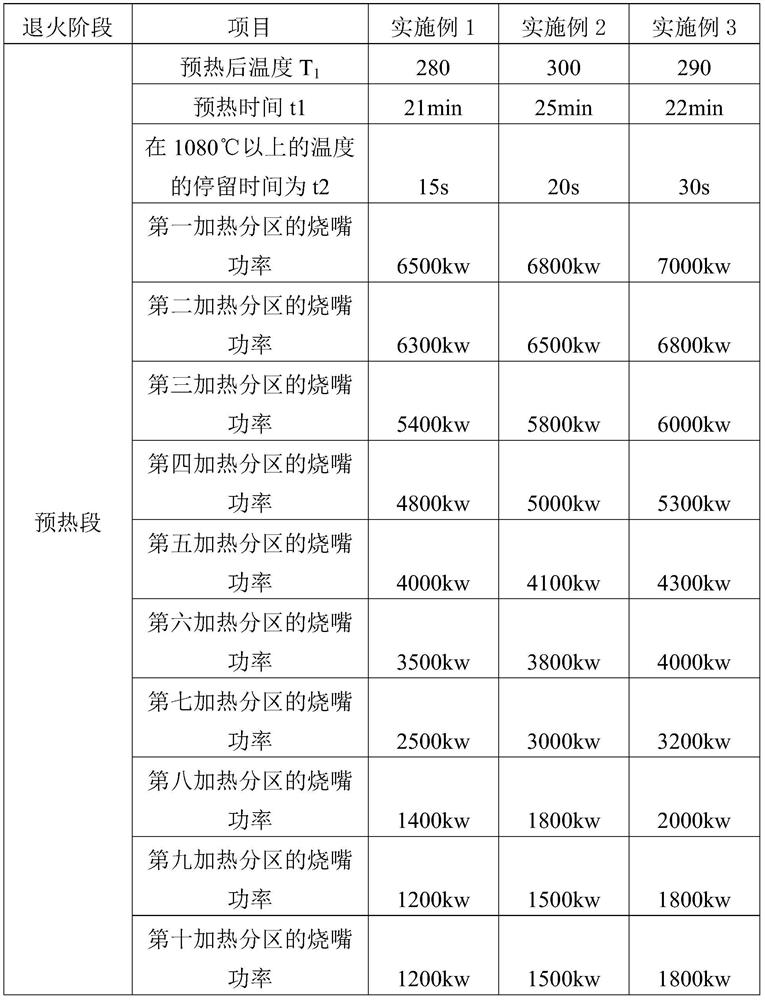

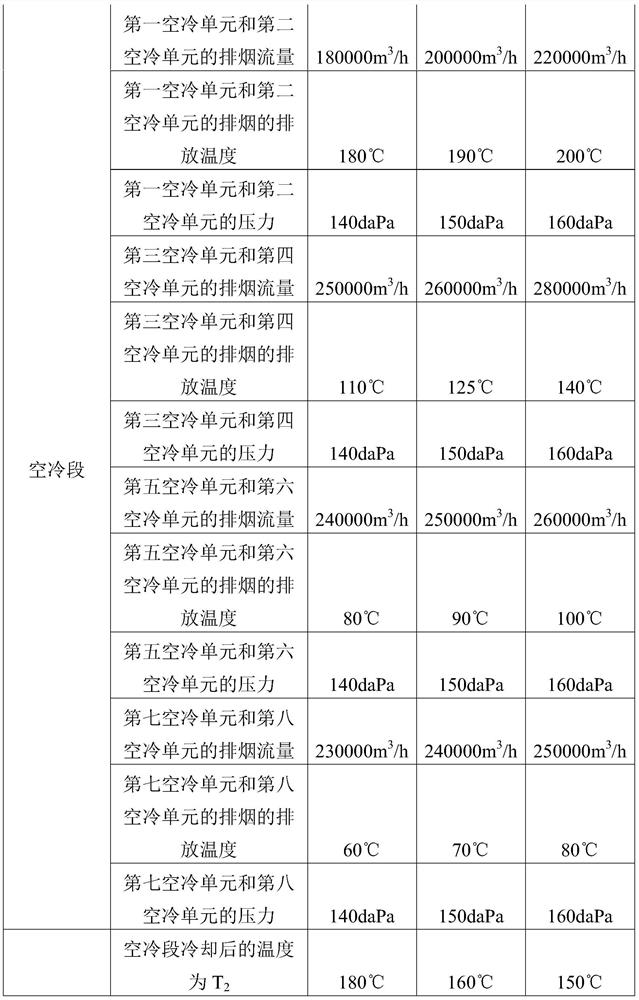

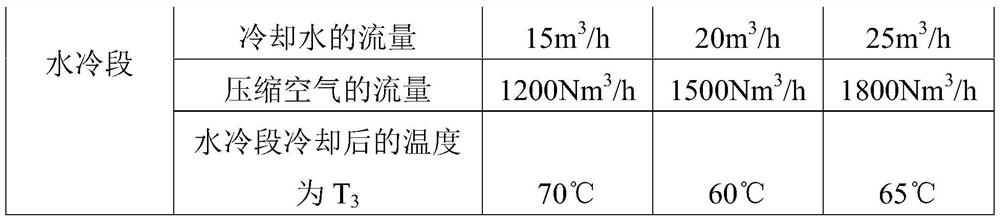

[0068] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below.

[0069] A kind of annealing method of stainless steel strip provided by the invention comprises:

[0070] (1) Transfer the cold-rolled stainless steel strip to the heating section of the annealing furnace, and directly heat the stainless steel strip through the flame ejected from the burner, so that the stainless steel strip is heated from 30°C to 1160°C, and the stainless steel strip At a temperature above 1080°C for at least 15 seconds.

[0071] The stainless steel strip is subjected to cold rolling treatment before annealing, and the cold rolling treatment includes:

[0072] Pass the stainless steel strip blank through the first cold rolling mill for the first pass of cold rolling, wherein the tension at the entrance of the first cold rolling mill is 240-260KN, and the tension at the exit of the first col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com