A kind of superfine bainitic bridge cable steel and preparation method thereof

A bainite type, bridge cable technology, applied in the field of bridge cable wire and its production, can solve the problems of long preparation time, several days or even tens of days

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] According to the chemical composition given in Table 1, it was melted and casted in a vacuum induction heating furnace.

[0031] Table 1 is the mass percent of each composition

[0032] Table 1

[0033]

[0034] The hot rolling process is to heat the steel billet to 1250°C for 3 hours, perform high-speed rolling, control the total reduction rate between 85% and 90%, and roll it into a wire rod with a diameter of 6-8mm. The temperatures were 1150°C and 950°C, respectively.

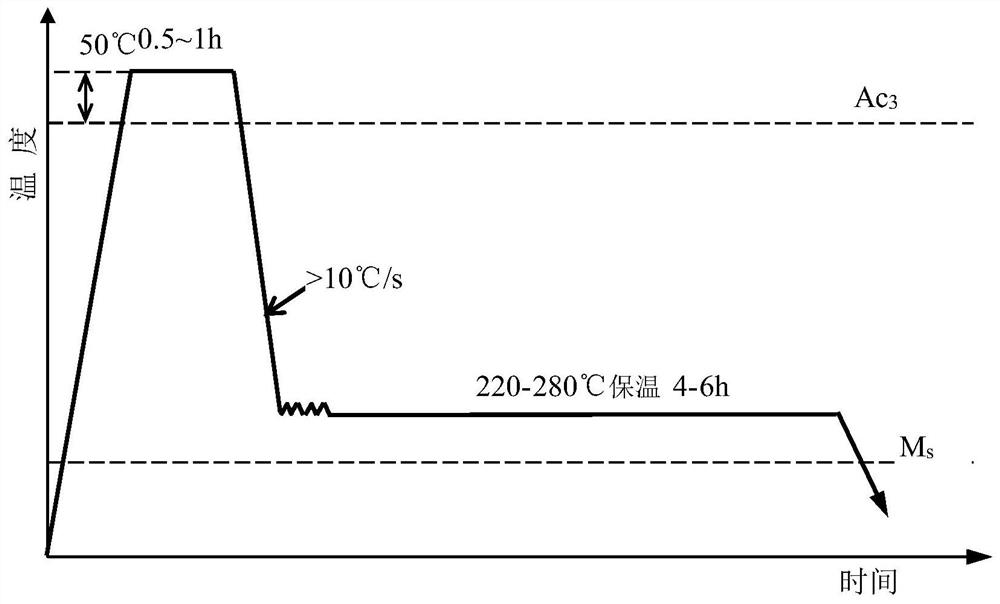

[0035] Heat the hot-rolled wire rod to 930°C in a resistance furnace, keep it warm for 0.5h, then put it into a salt bath furnace at 220°C-280°C to cool in a salt bath, and wait for 30s at the same temperature, then carry out warm rolling. 25%, and then quickly put it in a salt bath furnace at 220-280 °C for 3-5 hours and then air-cooled.

[0036] Table 2 shows the mechanical properties of ultra-fine bainitic cable steel at 220°C for 5 hours

[0037] Table 2

[0038]

[0039]

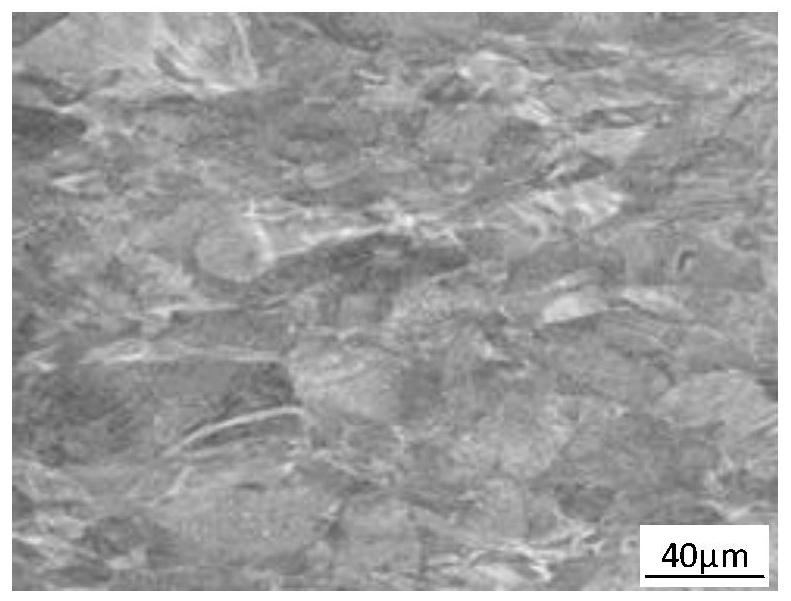

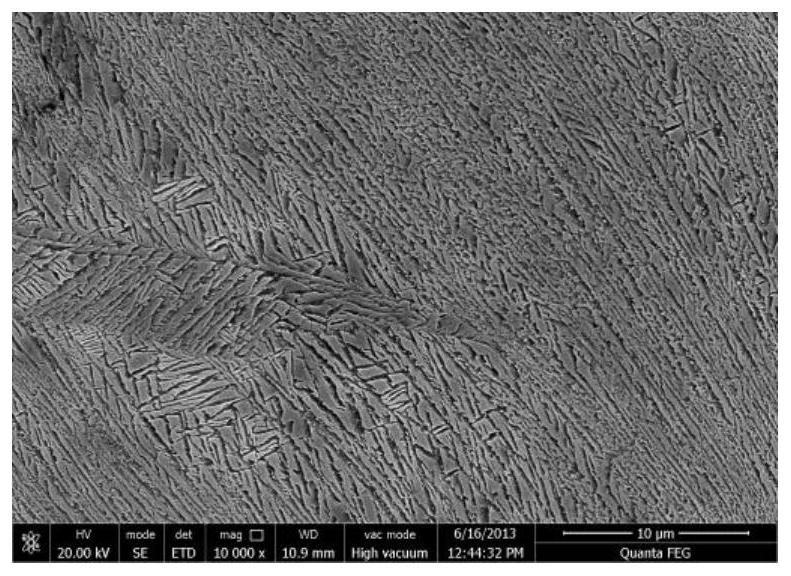

[0040] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com