Patents

Literature

34results about How to "Play a plasticizing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

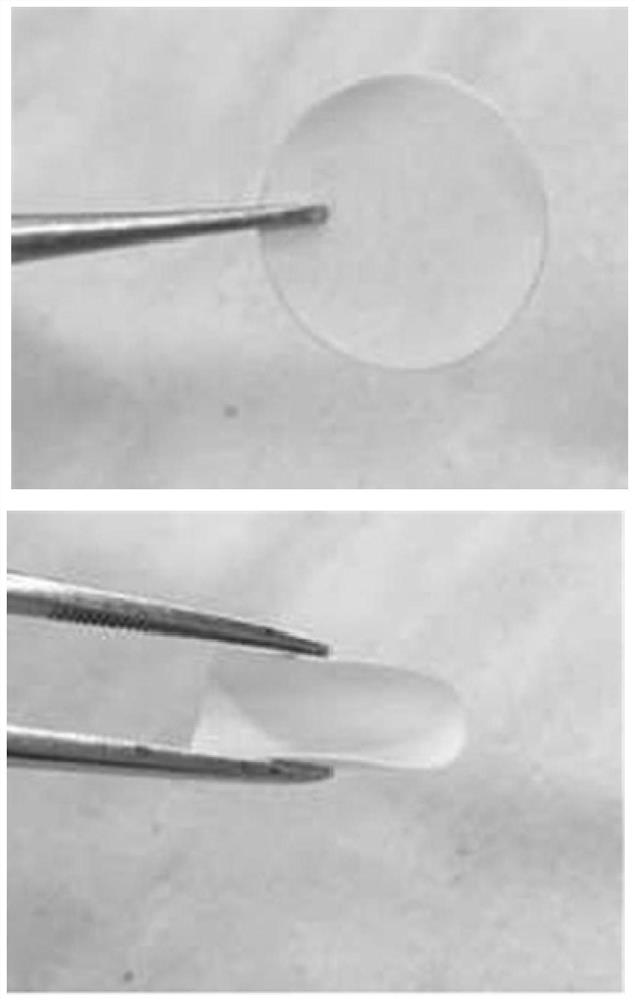

Method for preparing caster oil-based polyester serving as PVC (Polyvinyl Chloride) plasticizer

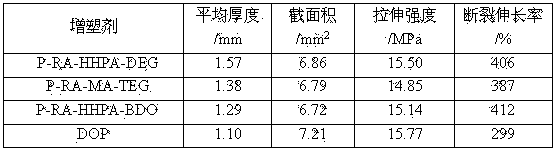

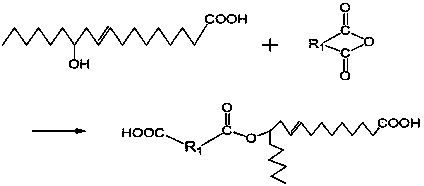

The invention discloses a method for preparing caster oil-based polyester serving as a PVC (Polyvinyl Chloride) plasticizer, belonging to the technical field of chemical synthesis. The method comprises the following steps: preparing caster oil-based dicarboxylic acid by reacting a down-stream product, namely, ricinoleic acid of low-price bio-based raw caster oil, dihydric anhydride and dihydric alcohol serving as raw materials in two steps: preparing caster oil-based dicarboxylic acid by using ricinoleic acid and dihydric anhydride, and carrying out a polyesterification reaction on the caster oil-based dicarboxylic acid and the dihydric alcohol in the coexistence of a catalyst and a water-carrying agent; and distilling under reduced pressure to obtain the caster oil-based polyester PVC plasticizer. A PVC plastic test piece is prepared by treating the caster oil-based polyester PVC plasticizer, PVC resin and a thermal stabilizer according to a certain formula through a solvent film casting method. The test piece is soft, and is equivalent to a PVC plastic piece plasticized by dioctyl phthalate (DOP) in the transparency under the same condition. The raw material is caster oil-based, recyclable, low in price and independent of petroleum, a preparation process is simple, and three wastes are not produced. The product is non-toxic, environment-friendly, resistant to migration, and superior in plasticizing performance, and has a good application prospect.

Owner:JIANGNAN UNIV

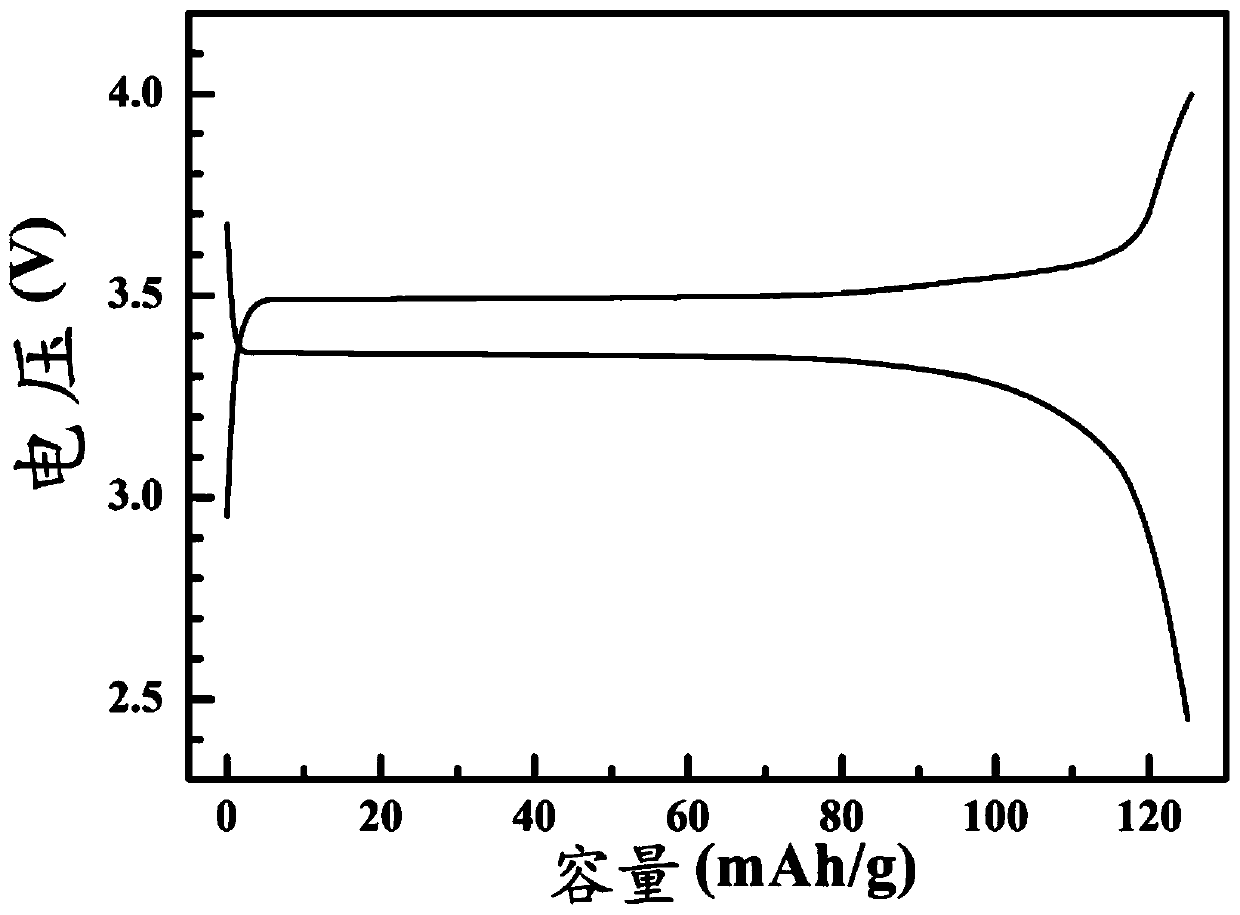

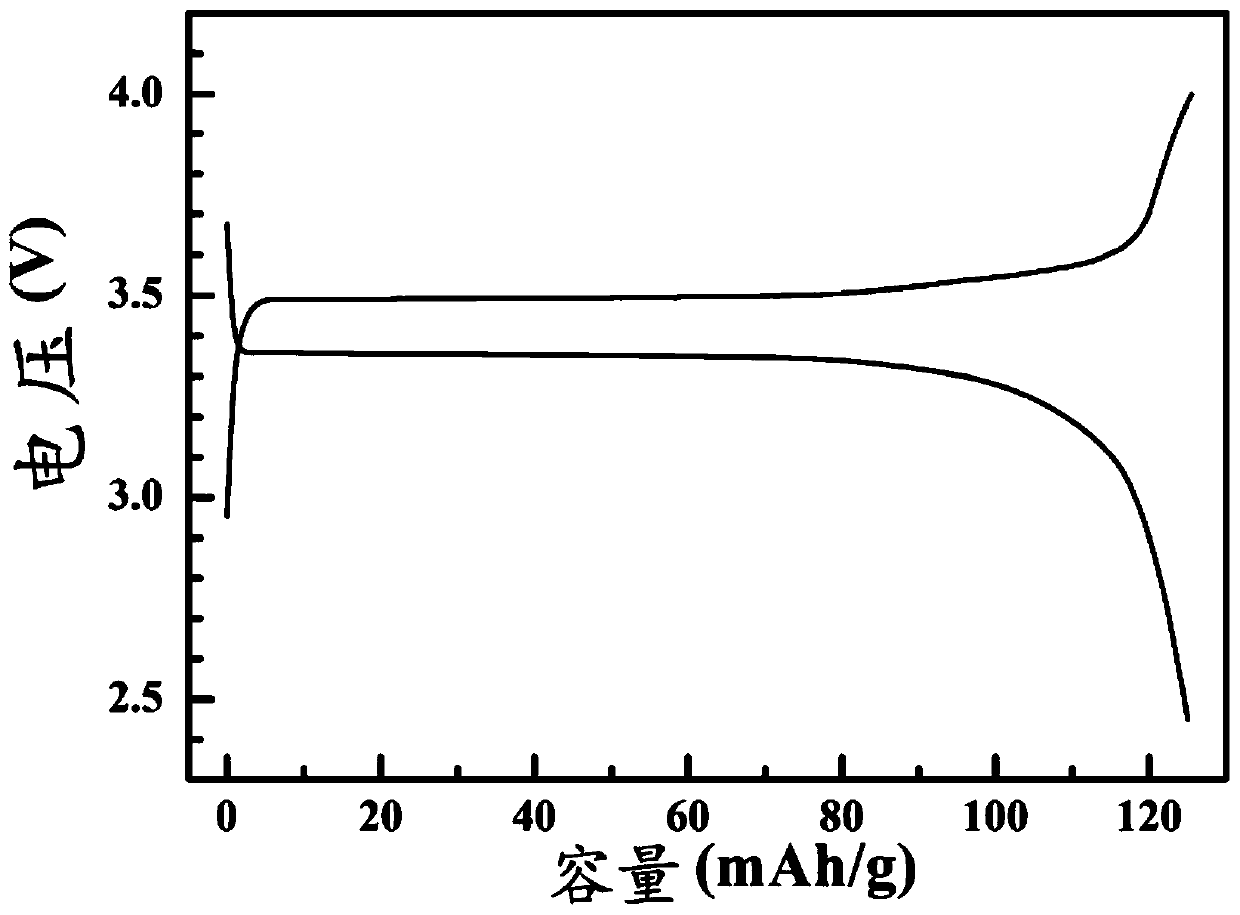

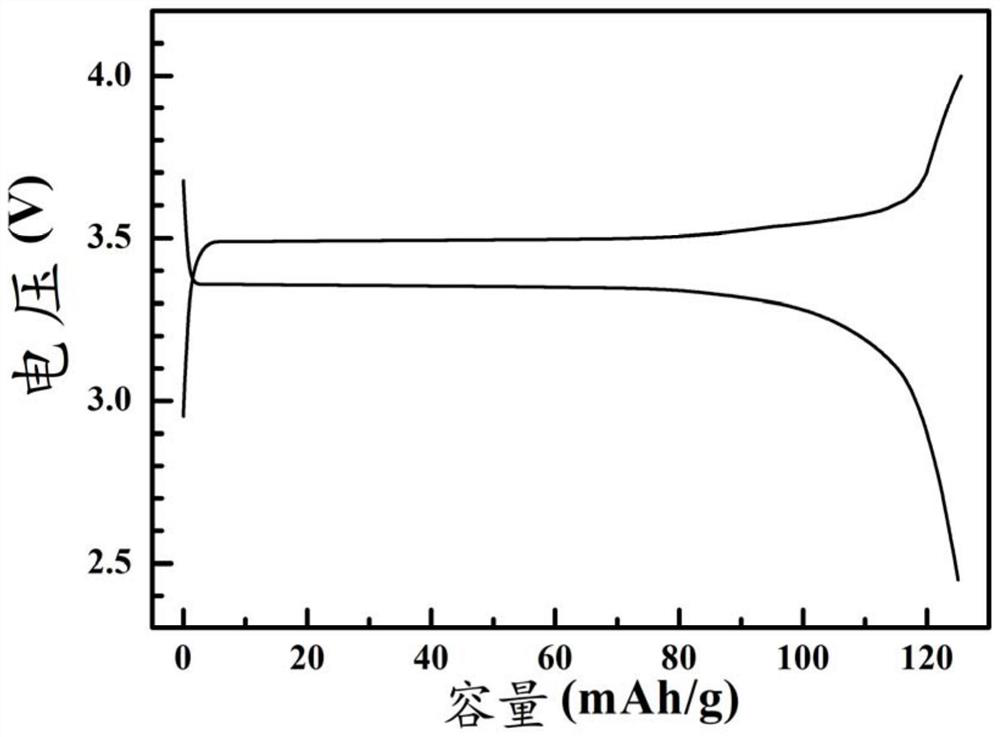

Solid electrolyte as well as preparation method and application thereof

ActiveCN110048156AImprove mechanical propertiesImprove conductivityFuel and secondary cellsFinal product manufactureSolid state electrolyteFluoropolymer

The invention discloses a solid electrolyte as well as a preparation method and application thereof. The solid electrolyte comprises a polymer phase, and a ceramic electrolyte and a lithium salt whichare dispersed in the polymer phase. The polymer phase is a fluoropolymer-polyacrylate copolymer. The preparation method comprises the following steps: 1) mixing fluoropolymer with an organic solvent,and reacting at 100-150 DEG C to obtain a modified fluoropolymer; and 2) mixing the modified fluoropolymer prepared in the step 1), the ceramic electrolyte, the lithium salt, an acrylate monomer andan initiator, and carrying out a polymerization reaction in an inert atmosphere to obtain the solid electrolyte. The solid electrolyte has the advantages of high mechanical strength, high toughness, high lithium ion conductivity, excellent interfacial compatibility with a metal lithium negative electrode and an oxide positive electrode and high chemical / electrochemical stability, and can be applied to a metal lithium battery, a lithium air battery and a lithium-sulfur battery.

Owner:ZHEJIANG UNIV

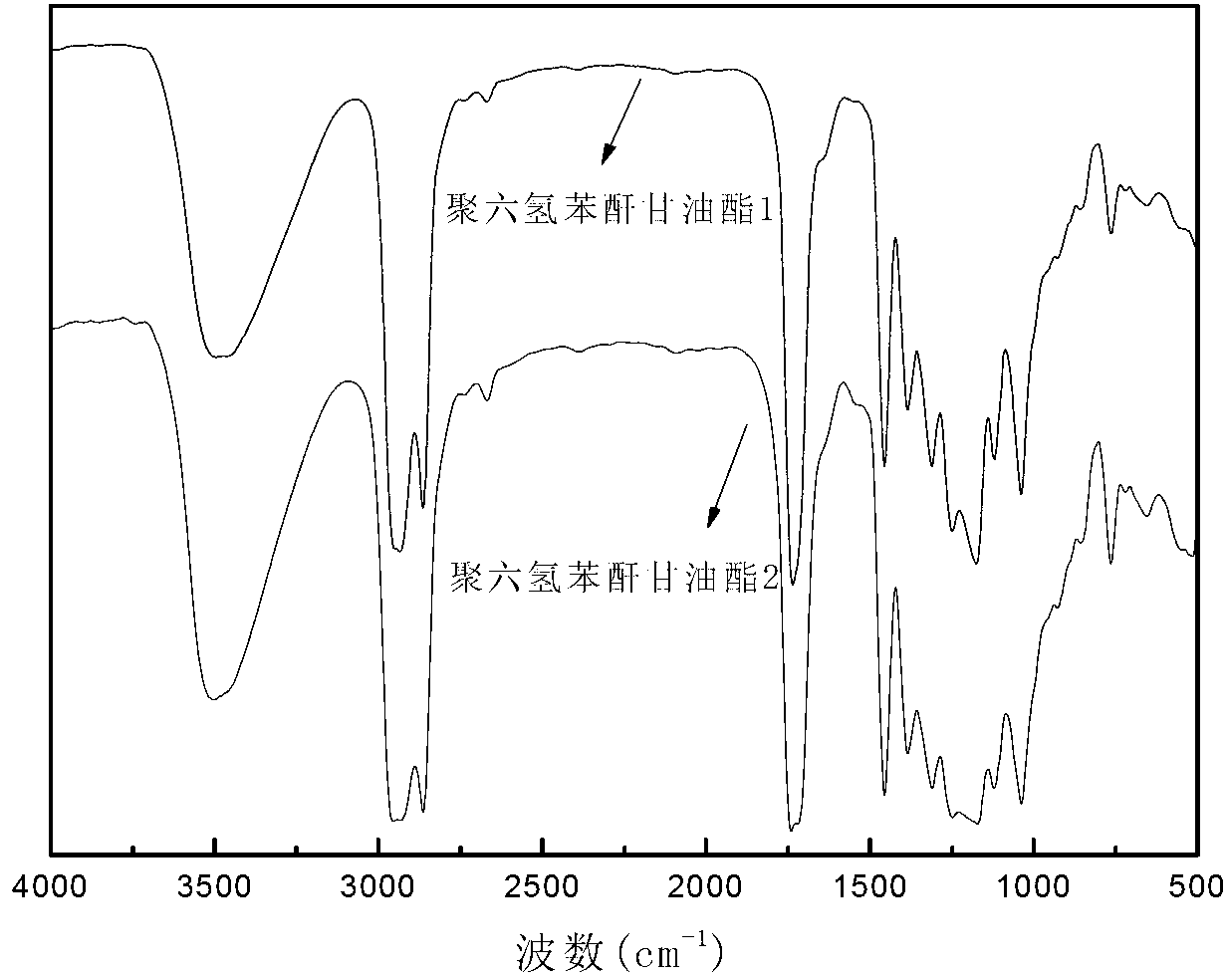

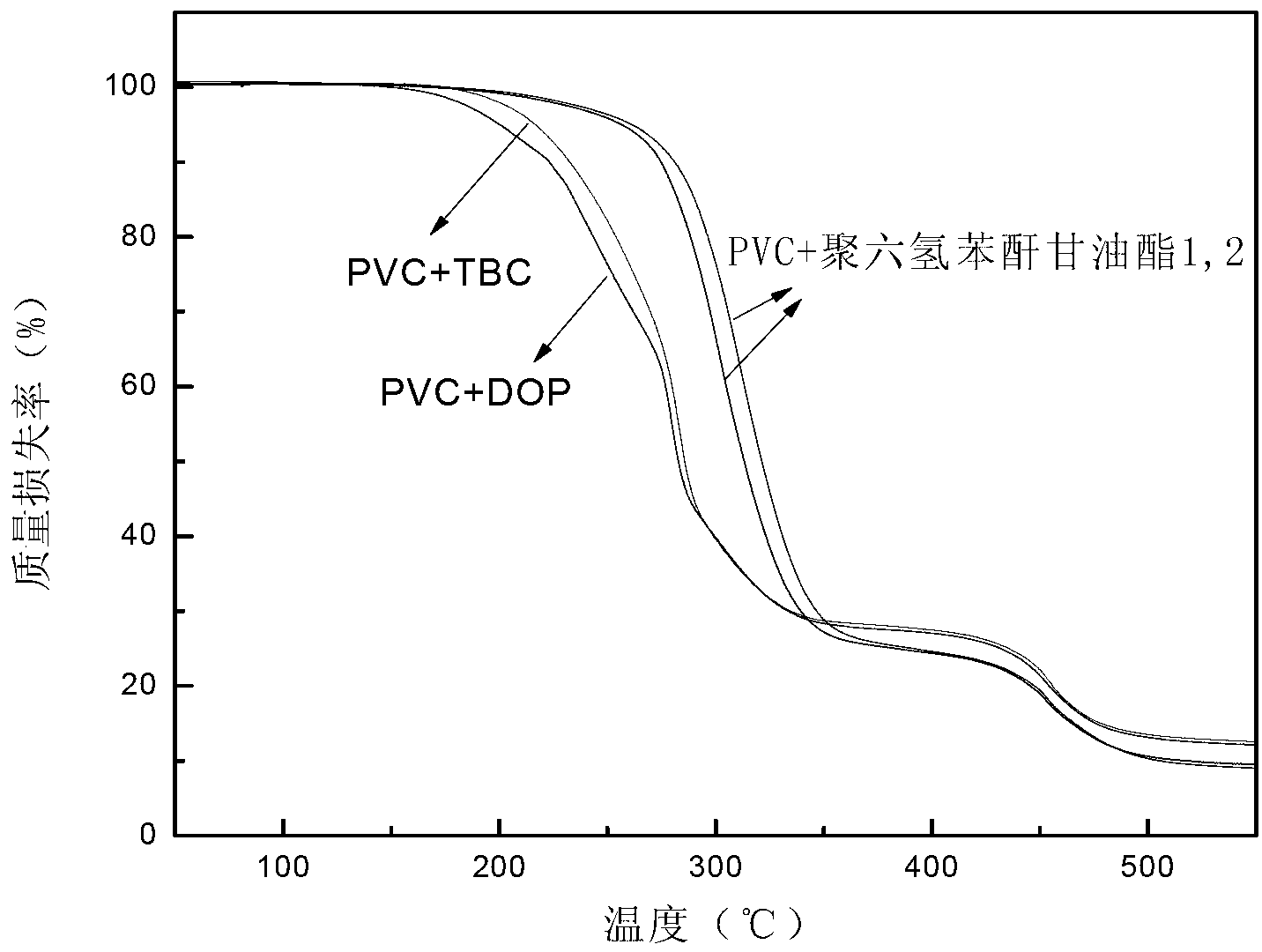

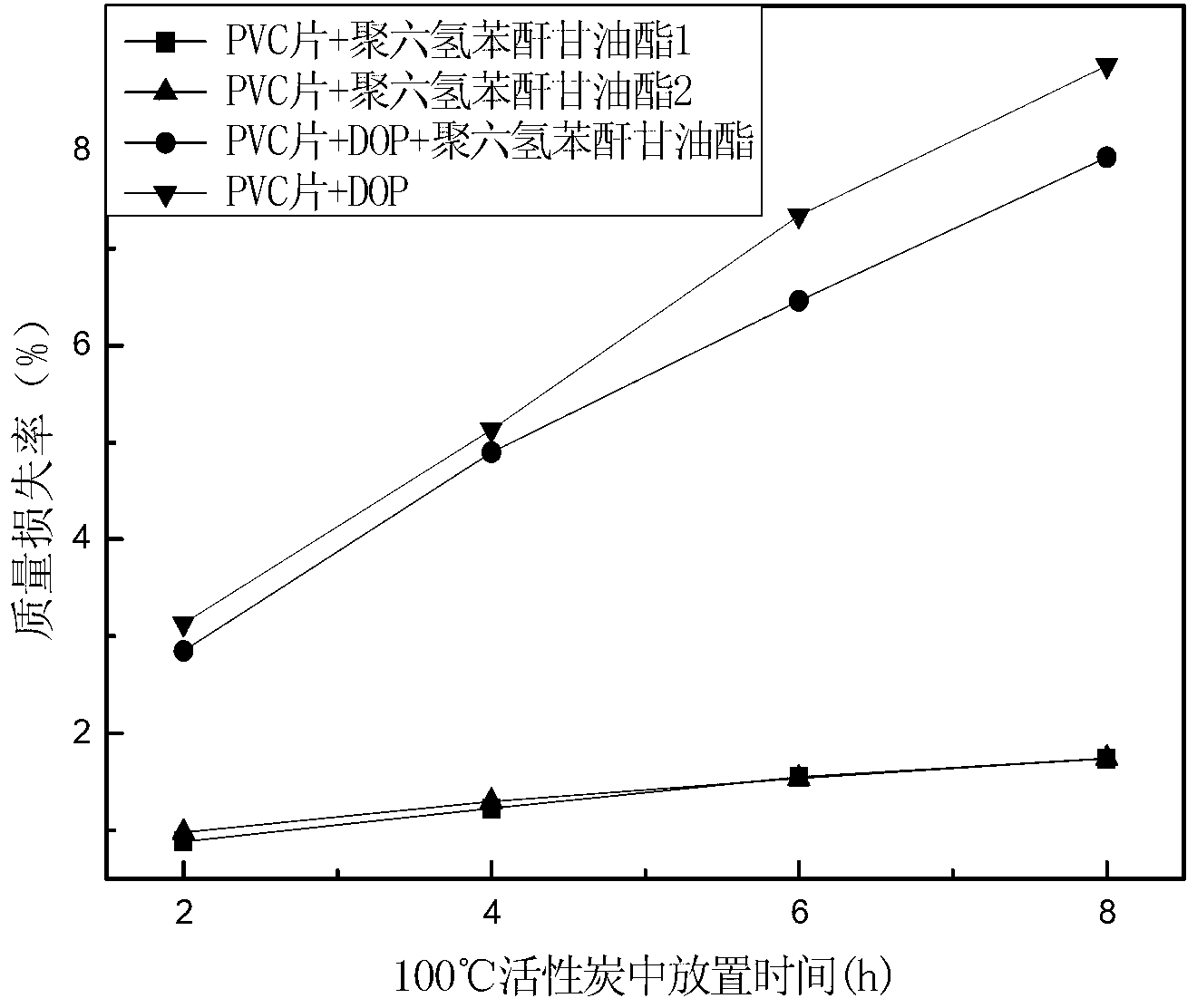

Preparation method of glyceryl polyester used as PVC (Polyvinyl Chloride) plasticizer

InactiveCN103242516AThe synthesis process is simpleReduce energy consumptionDispersion coefficientChemical synthesis

The invention discloses a preparation method of glyceryl polyester used as a PVC (Polyvinyl Chloride) plasticizer and belongs to the technical field of chemical synthesis. The preparation method comprises the following steps of: synthesizing by a one-step process under the combined action of a catalyst, an end-capping reagent and a water-carrying agent by using cheap bio-based glycerol, non-orthophthalic binary acid (for example hexahydrophthalic anhydride, adipic acid or the like) as the materials; and carrying out the post-treatment processes including dehydration poly-condensation, reduced pressure distillation and the like to obtain the poly-binary acid glyceride plasticizer. The glyceride plasticizer has a final acid value of 0.7mgKOH.g<-1>-2mgKOH.g<-1>, an esterification rate higher than 97%, relative molecular weight of about 5000, a dispersion coefficient of 1.00-1.13, appropriate viscosity and stable physical and chemical characteristics; the glyceride plasticizer is added to the PVC according to a certain formula to be refined into a PVC plastic test block, so that application performances including heat stability, drawing resistance, tensile performance and the like of the test block are tested; and the test block has good heat stability, tensile performance and excellent mobility resistance. The preparation method of the glyceryl polyester used as the PVC plasticizer is low in material price, simple in preparation process, low in energy consumption, excellent in product performance and good in application prospect.

Owner:JIANGNAN UNIV

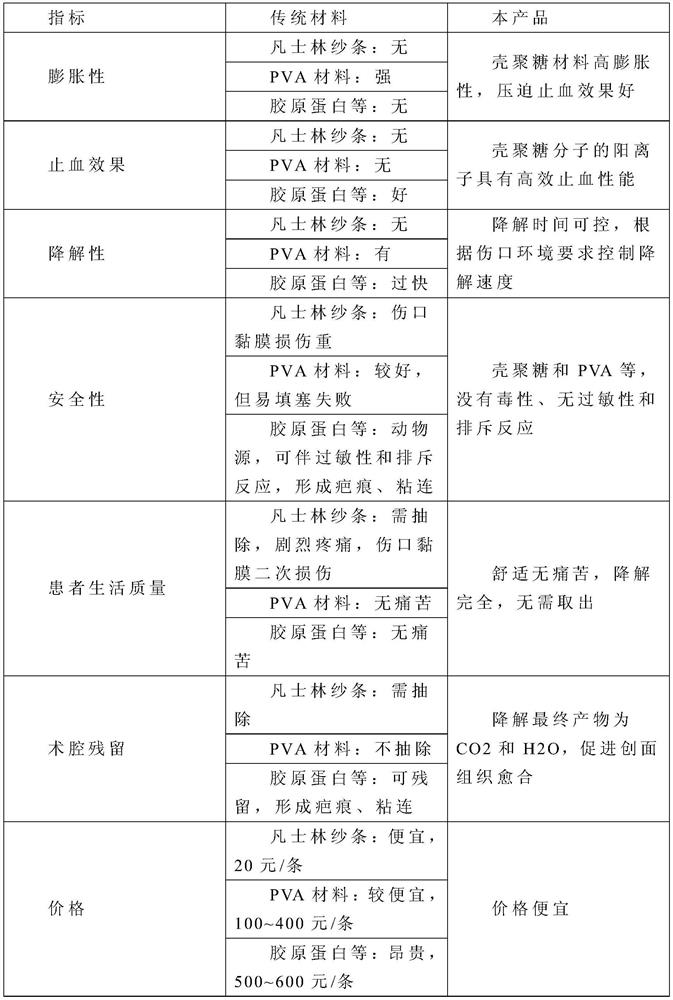

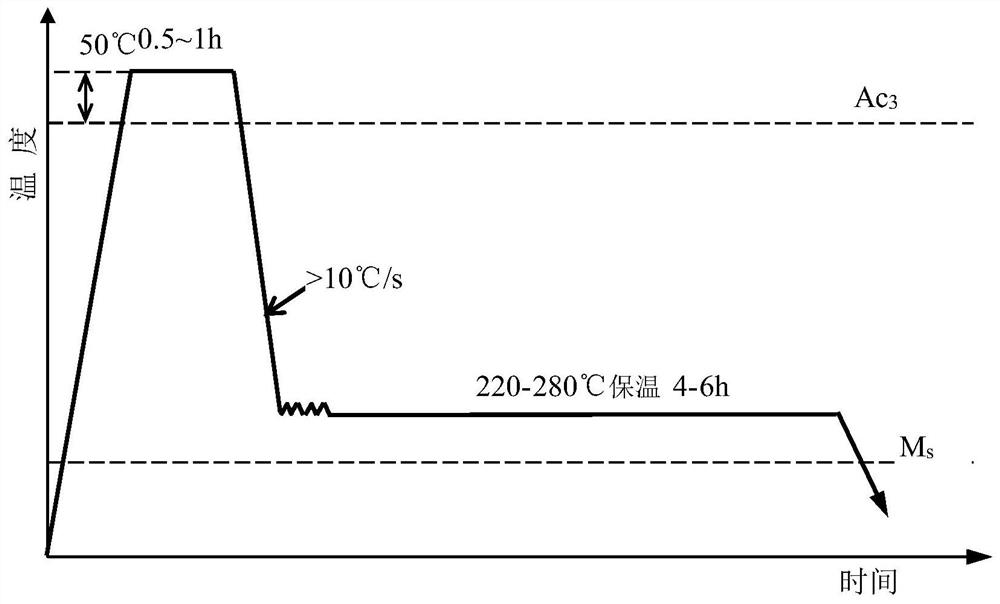

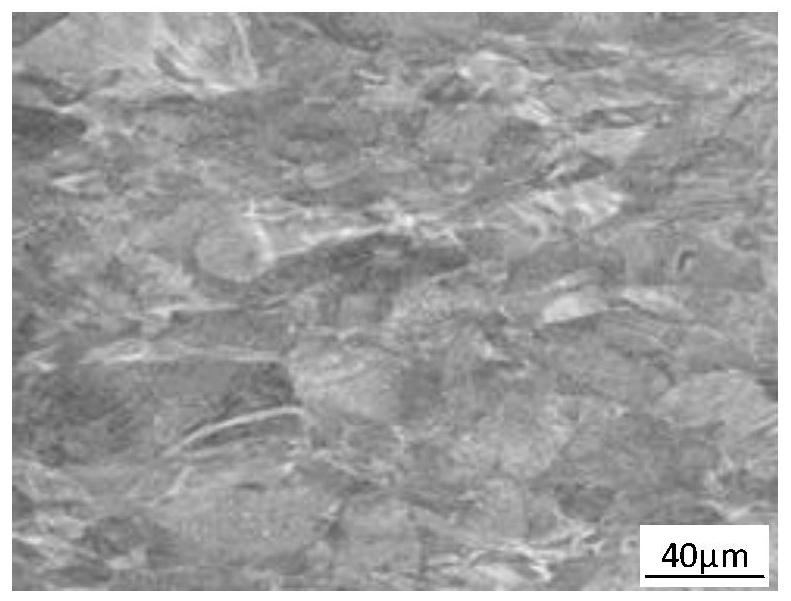

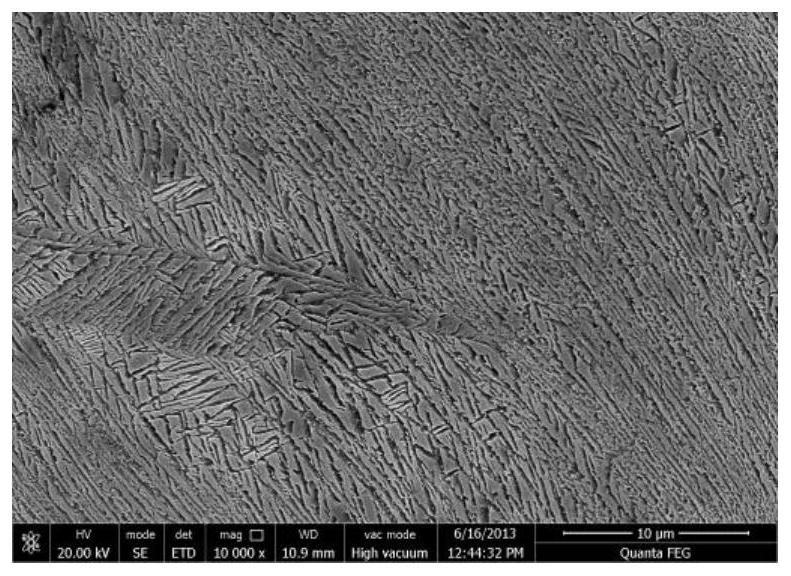

Ultrafine bainite bridge cable steel and preparing method thereof

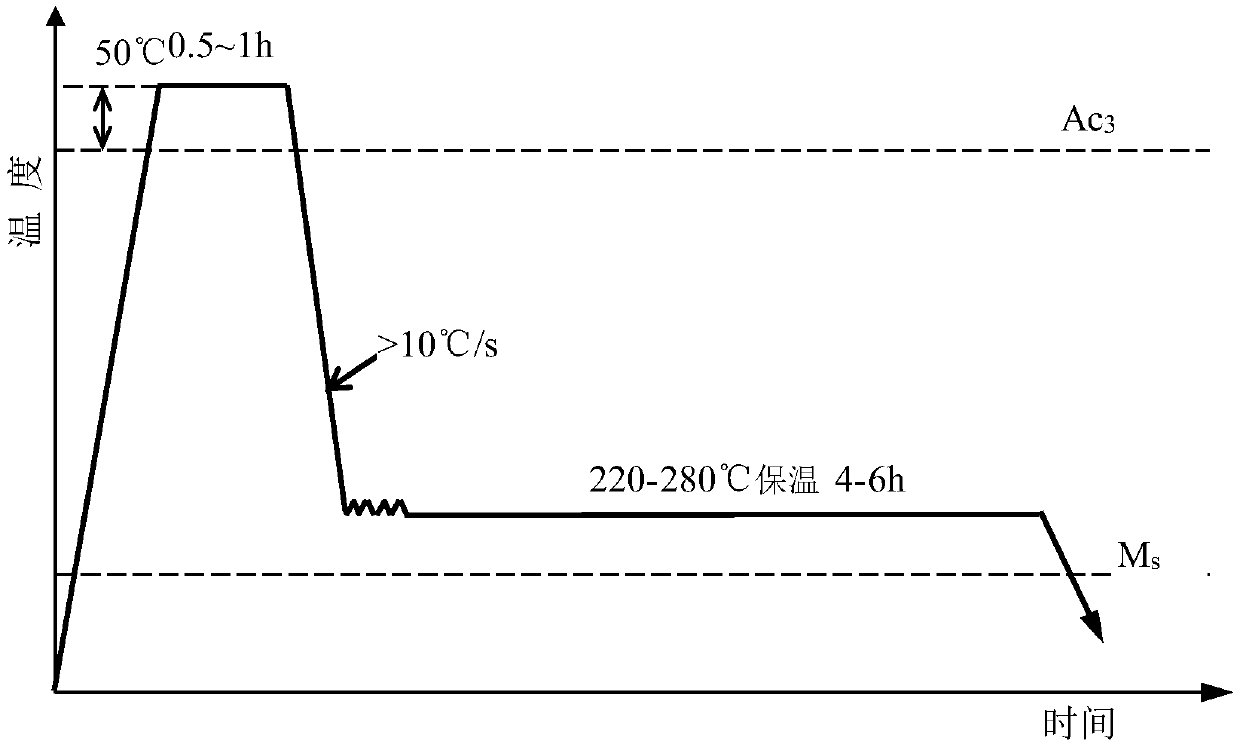

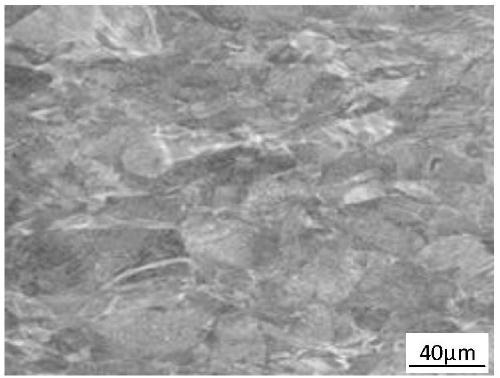

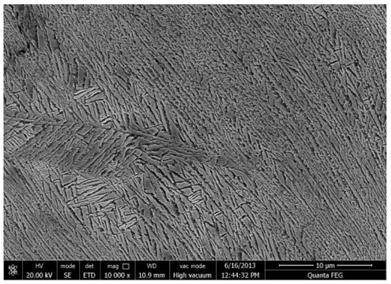

The invention discloses ultrafine bainite bridge cable steel and a preparing method thereof, and belongs to wires for bridge cables and production thereof. The thermo-mechanical treatment + isothermalquenching technology is adopted for obtaining the cable steel; pre-deformation and low-temperature bainite isothermality are combined, refining technologies of microalloy refinement, controlled rolling and cooling refining, pre-deformation and low-temperature bainite isothermality are comprehensively used, an ultrafine bainite structure composed of non-carbonization bainite and retained austeniteis obtained, the tensile strength of the structure ranges from 1800 to 2100 MPa, and the ductility of the structure ranges from 12 to 20%; the preparing process of the ultrafine bainite bridge cablesteel comprises the steps of smelting, continuous casting, hot rolling, cutting, austenitizing, pre-deforming and low-temperature bainite isothermality. During pre-deforming, firstly, a cut hot-rolledwire rod is heated again to Ac3+50 DEG C to be subjected to austenitizing, heat preservation is carried out for 0.5 to 1 h, rapid cooling (the cooling speed is larger than 10 DEG C / s) to 220 to 280 DEG C is carried out, further warm rolling is carried out, the rolling reduction is 20 to 30%, then, the wire rod is put into a salt bath furnace at the temperature of 220 to 280 DEG C to be subjectedto isothermality treatment for 3 to 5 h, and isothermality bainite conversion is carried out; and the wire rod is taken out and subjected to air cooling to the room temperature.

Owner:UNIV OF SCI & TECH BEIJING

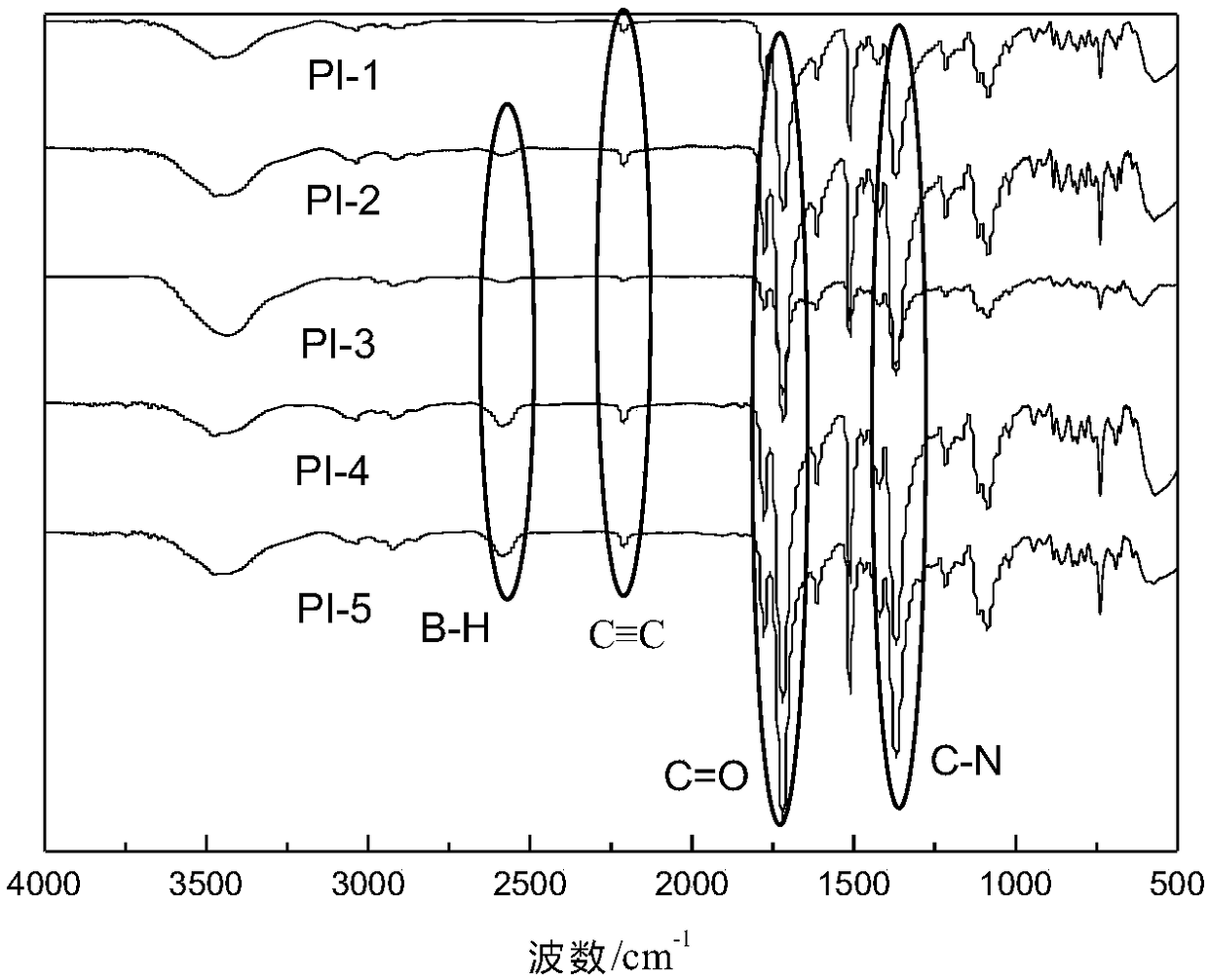

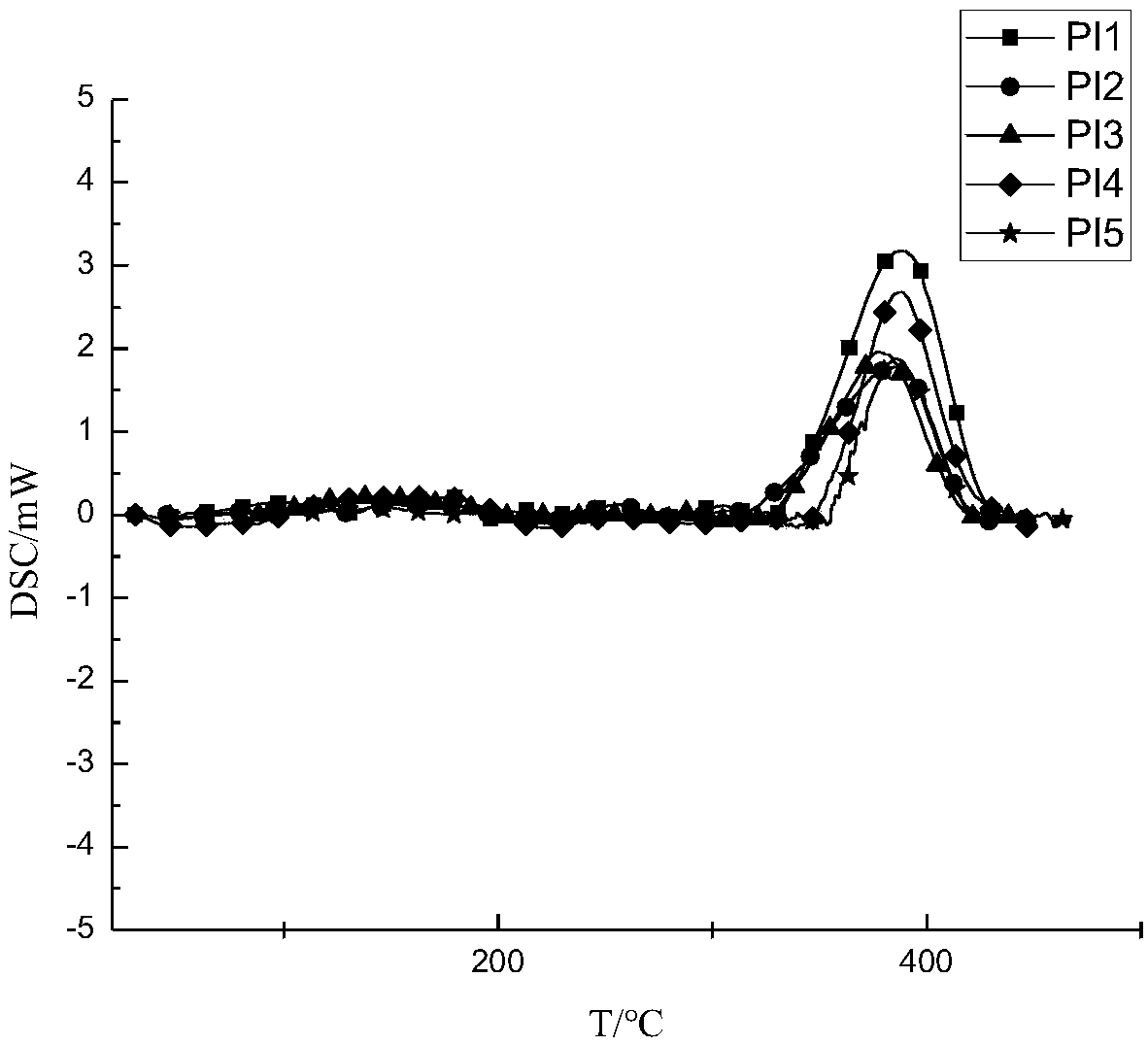

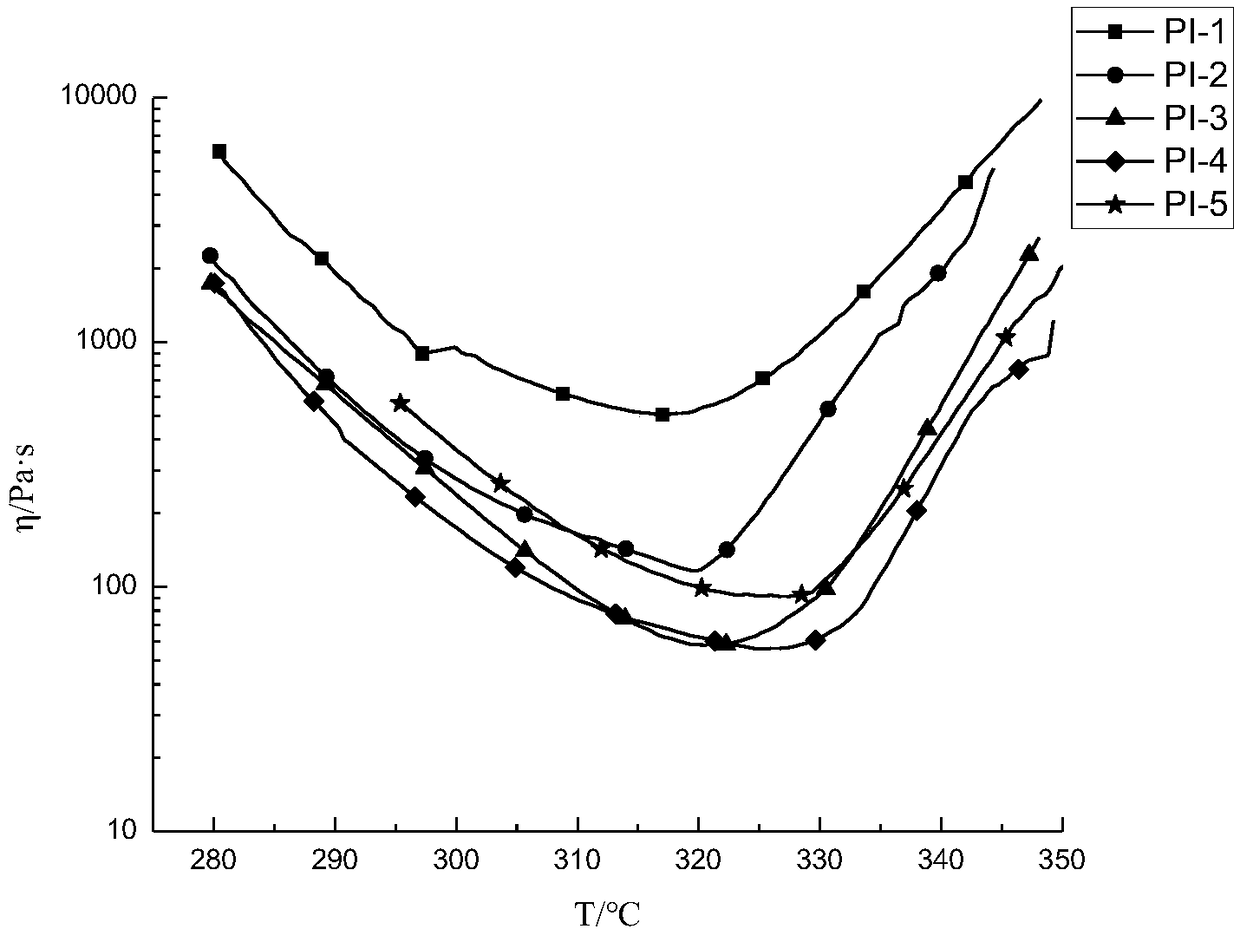

Low viscosity polyimide copolymerized thermosetting resin and preparation method and application thereof

The invention relates to the technical field of high molecular materials, and particularly relates to copolymerized polyimide thermosetting resin comprising a carborane structure and a preparation method and an application thereof. The copolymerized polyimide resin is prepared by thermally cross-linking and solidifying polyimide oligomers represented by a formula I as a raw material. The oligomersintroduce the carborane of a certain composition into a conventional thermosetting polyimide resin system by means of a copolymerization method, so that the conventional thermosetting polyimide resinhas relatively low hot melt viscosity and a higher glass-transition temperature (higher than 500 DEG C) and also has more excellent thermal oxidation resistance and heat stability resistance. Therefore, the thermosetting resin has the extremely low hot melt viscosity. The resin is more easily prepared into a composite material part of a complex structure through a conventional processing technology, can improve the thermal oxidation resistance of the material to a great extent, and has very high application value and innovation to prepare a light high strength high-temperature-resistant easily processed polyimide composite material for a structural material in the aerospace field.

Owner:BEIHANG UNIV

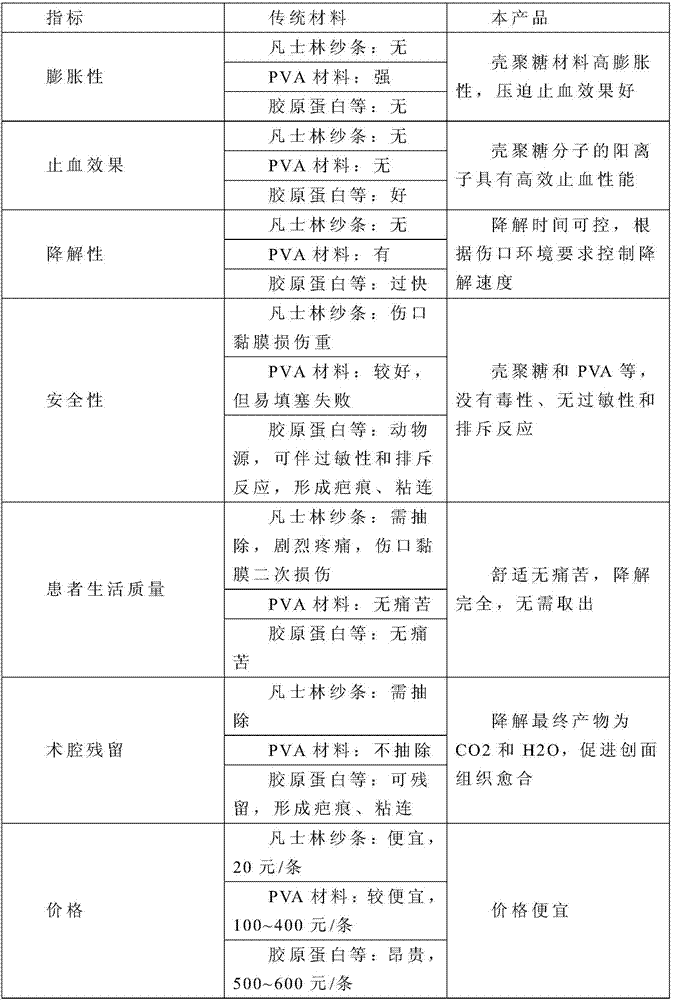

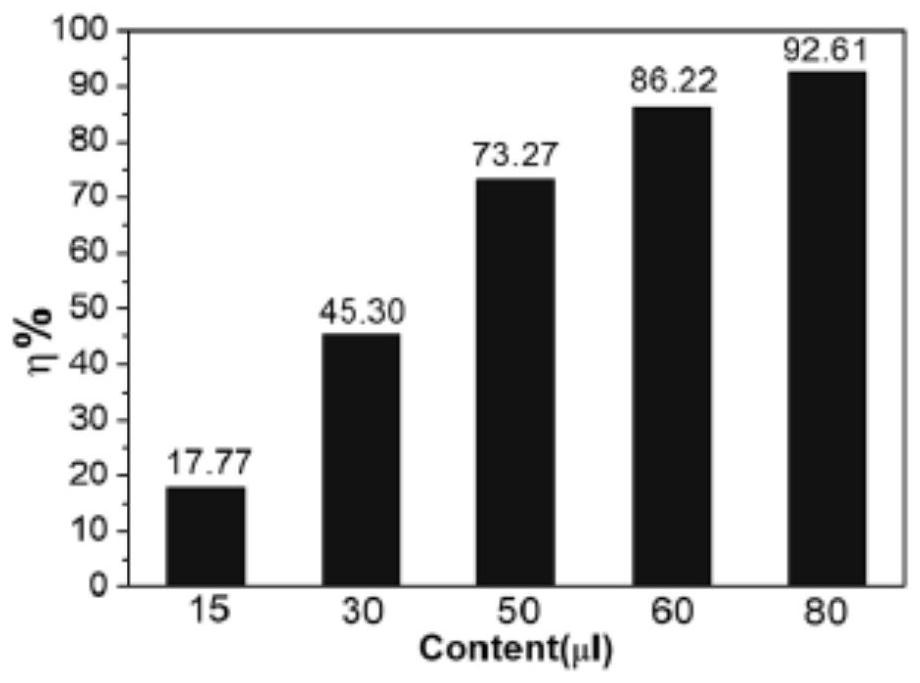

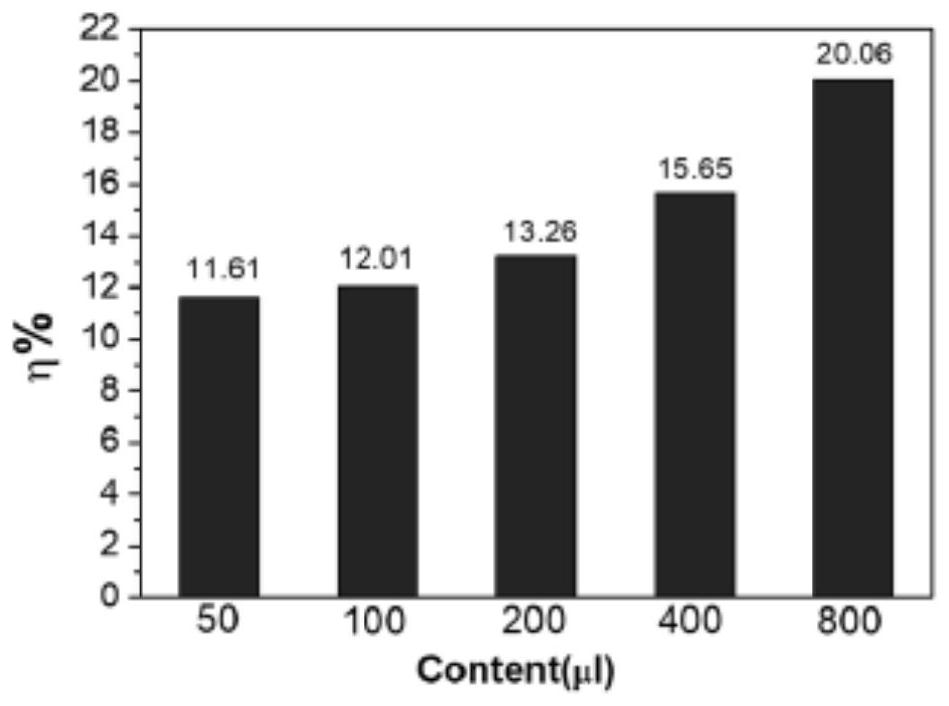

Hemostatic material and preparation method thereof

ActiveCN107261193ARapid hemostasisGood squeeze to stop bleedingPharmaceutical delivery mechanismAbsorbent padsPolyvinyl alcoholMedicine

The invention belongs to the field of medical hemostatic materials and particularly relates to a hemostatic material and a preparation method thereof. The hemostatic material is prepared from raw materials in parts by weight as follows: 0.1-1.5 parts of carboxymethyl chitosan, 0.5-2 parts of PVA (polyvinyl alcohol), 0.2-5 parts of a compound toughening substance (named a plasticizing system hereinafter) and 0.5-1.5 parts of an ionic crosslinking agent. The hemostatic material can further comprise 0.5-3 parts by weight of a wide-spectrum hemostatic antibacterial agent. The product has good mechanical elasticity, can realize rapid hemostasis, can be completely degraded, is non-toxic and high in antibacterial property and is applicable to wound hemostasis, preferably body cavity hemostasis and especially applicable to nasal cavity hemostasis.

Owner:BEIJING TONGREN HOSPITAL AFFILIATED TO CAPITAL MEDICAL UNIV

PVC composite plate and preparation method thereof

InactiveCN108239356ALow densityHigh compressive strengthSynthetic resin layered productsAgricultural engineeringComposite plate

The invention discloses a PVC composite plate. The PVC composite plate is of a composite layer structure and comprises outer panel layers and an inner panel layer arranged between the outer panel layers, wherein the outer panel layers contain the following components in parts by weight: 47-58 parts of PVC resin, 32-38 parts of nano-light calcium carbonate, 5-7 parts of a calcium-zinc stabilizer, 0.98-1.42 parts of an inner lubricant, 1-1.5 parts of a PVC foaming modifier, 0.18-0.22 part of ACR-401 and 1-1.5 parts of titanium dioxide. The invention further discloses a preparation method of thePVC composite plate. According to the PVC composite plate provided by the invention, the density of the PVC composite plate is reduced, the integral strength of a product is enhanced, and light and pressure-proof effects are achieved.

Owner:湖南五祥新材料科技有限公司

Refractory ceramic product and manufacturing technology thereof

InactiveCN106866107AReduce manufacturing costMaintain ecological balanceClaywaresManufacturing technologyHardness

The invention provides a refractory ceramic product and a manufacturing technology thereof and relates to the technical field of ceramics. The refractory ceramic product comprises 200-350 weight parts of blanks, 50-100 weight parts of glazes and 20-40 weight parts of auxiliaries. The raw material composition and the manufacturing technology of the refractory ceramic product provided by the invention are both strictly controlled; at the aspect of the raw materials, blanks, glazes and auxiliaries are reasonably prepared, so that the roasted ceramic product has excellent high temperature resistance, chemical stability, hardness and toughness; at the aspect of the technology, an once-firing manner is adopted for roasting the ceramic, so that the shovel strength is increased and the cost is lowered; besides, a method for gradually increasing temperature and roasting in stages is adopted for roasting, so that the cracking and uneven surface caused by the rapid loss of the ceramic water can be avoided, the yield of the product can be greatly increased and the refractory ceramic product is worthy of popularization in the market.

Owner:玉林龙升建筑装饰工程有限公司

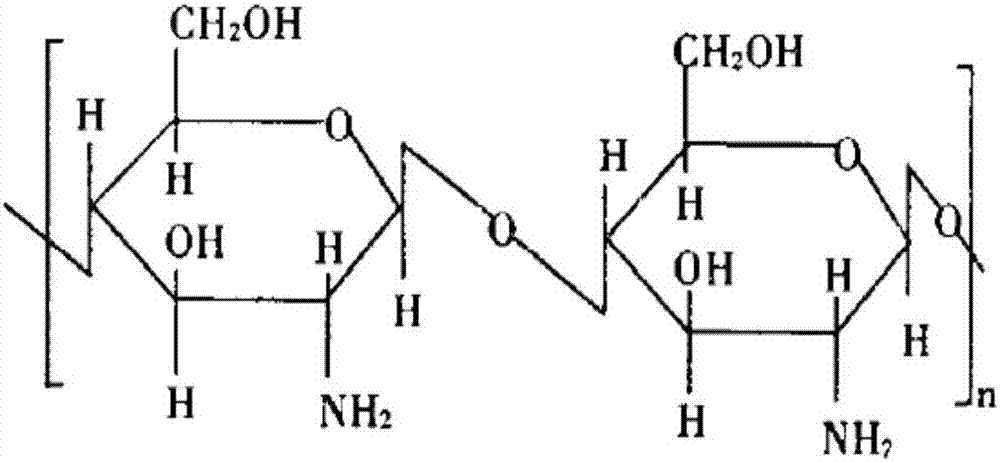

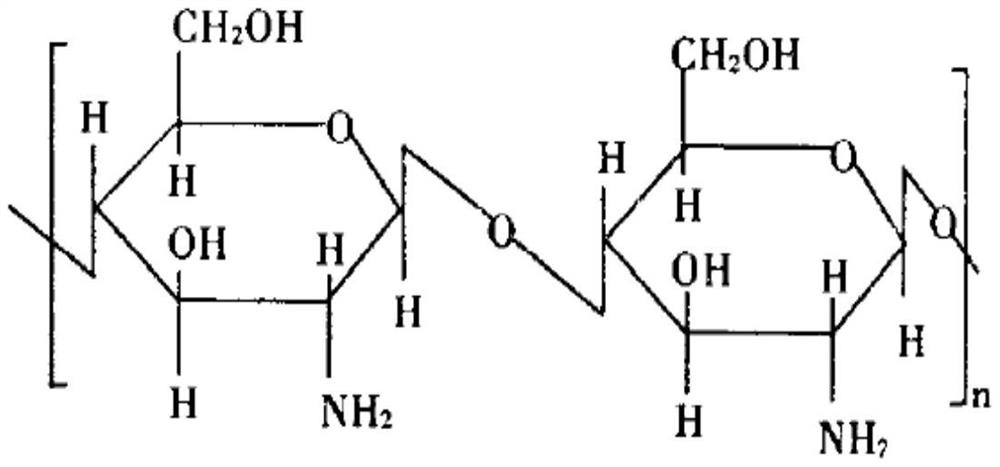

Preparation method and application of natural ionic liquid preservative film

The invention relates to the field of multifunctional film materials, in particular to a preparation method and application of a natural ionic liquid preservative film. The preparation method of a natural ionic liquid preservative film comprises the following steps of: S1, preparation of ionic liquid: respectively dissolving an acidic component and an alkaline component in a solvent to obtain an acid solution and an alkaline solution, adding the acid solution into the alkaline solution, stirring for 4-24 hours in a nitrogen protection atmosphere after the acid solution is added, so as to uniformly mix the acid solution and the alkaline solution, and removing the solvent through a vacuum rotary evaporation method to obtain the ionic liquid; and S2, preparation of the natural ionic liquid preservative film: adding the ionic liquid into a natural polymer aqueous solution, uniformly mixing to obtain a mixed solution, performing ultrasonic treatment on the mixed solution for 30-90 minutes, pouring the mixed solution into a glass dish with a smooth interior, and putting the glass dish into a drying oven at 40-80 DEG C for 12-28 hours to obtain the natural ionic liquid preservative film. The prepared natural ionic liquid preservative film not only has good mechanical properties, but also has the functions of bacteriostasis, oxidation resistance and the like.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Environmental-friendly PP edge sealing strip and preparation method thereof

The invention relates to the technical field of edge sealing strips, in particular to an environmental-friendly PP edge sealing strip and a preparation method thereof. The environmental-friendly PP edge sealing strip comprises the following raw materials in parts by weight: 75-125 parts of PP resin, 10-25 parts of nanometer active calcium carbonate, 10-25 parts of talcum powder, 0.5-3 parts of dioctyl adipate, 2-10 parts of a modifying auxiliary agent, 0.3-1.5 parts of a lubricating agent, 1.0-3.0 parts of an antistatic agent, 0.1-0.8 part of an ultraviolet absorbent, 0.2-1.5 parts of an antioxidant and 0.5-1.5 parts of a toner. The environmental-friendly PP edge sealing strip does not contain phthalate, heavy metals and other harmful substances, and is environment-friendly, light, non-toxic, high in impact resistance, good in flexibility, strong in weather resistance and excellent in comprehensive physical properties.

Owner:XIONG YI PLASTIC PROD CO LTD

Environment-friendly degradable polyethylene plastic bag

InactiveCN107903477AImprove thermal stabilityImprove antioxidant capacityPolymer scienceSodium Bentonite

The invention discloses an environment-friendly degradable polyethylene plastic bag, and relates to the technical field of plastic bags. The environment-friendly degradable polyethylene plastic bag isprepared from the following components by mass: 15 to 20% of modified starch and 10 to 12% of silanization bentonite. The environment-friendly degradable polyethylene plastic bag has the advantages that by adding the modified starch and the silanization bentonite into the polyethylene plastic system, the crosslinking due to heat aging in the preparation process of the plastic bag can be prevented, the gelling can be prevented, the heat stability and anti-oxidizing property of the prepared plastic bag are greatly improved, the compatibility between the components is improved, and the plasticizing effect is realized; the prepared plastic bag has excellent biodegradability.

Owner:全椒县三安塑业有限公司

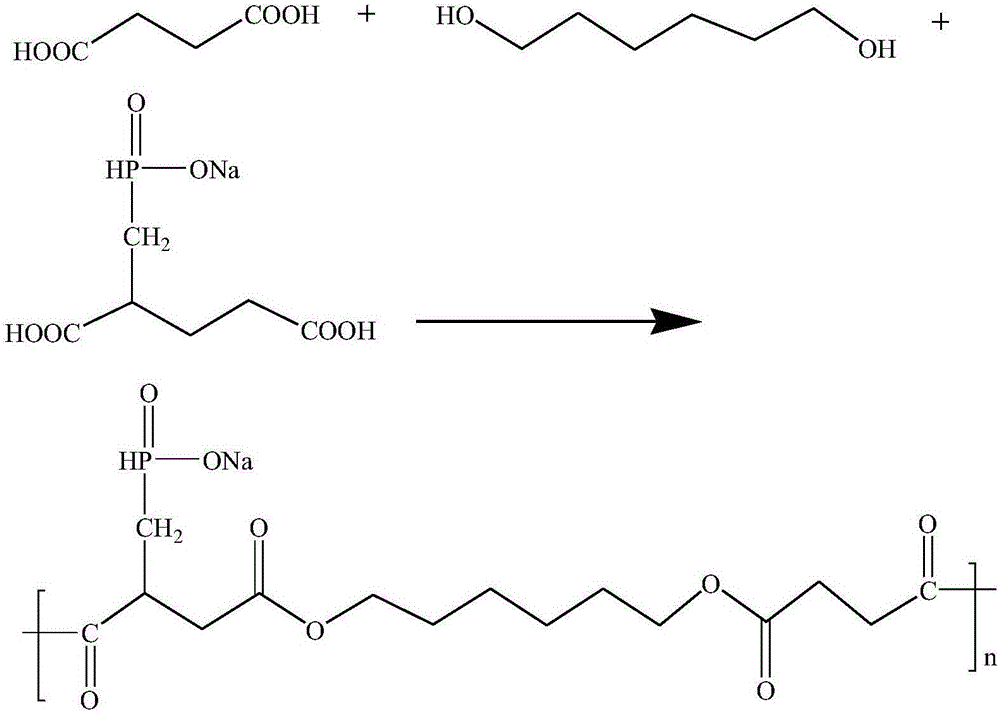

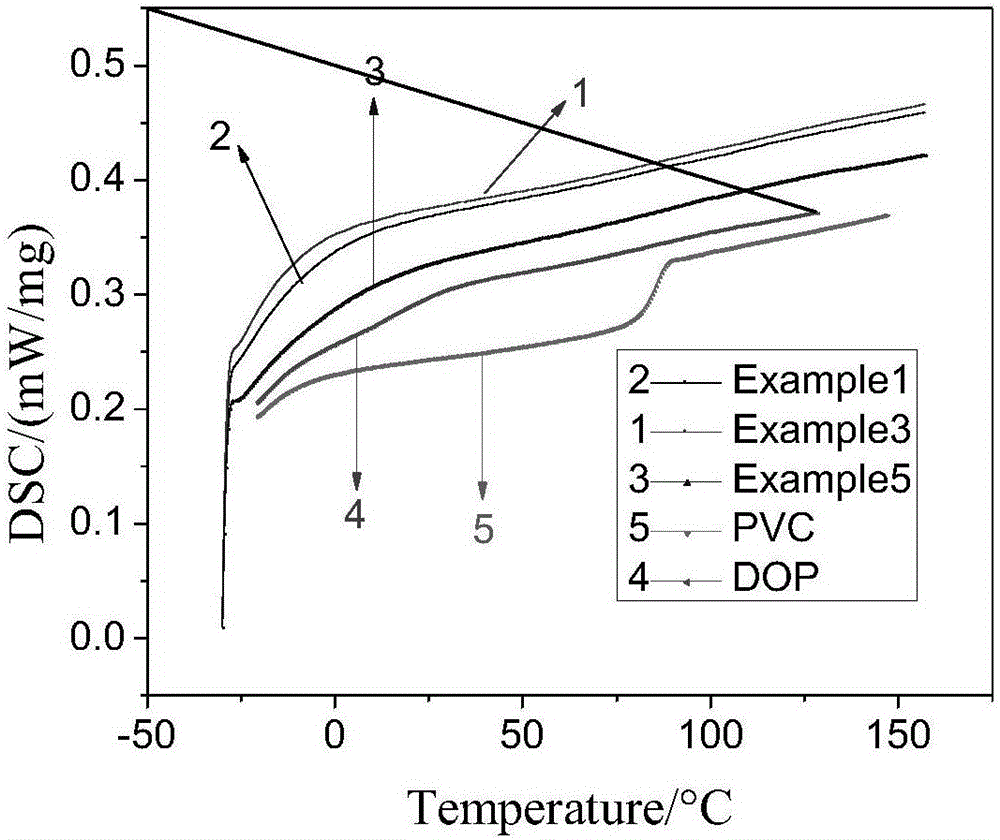

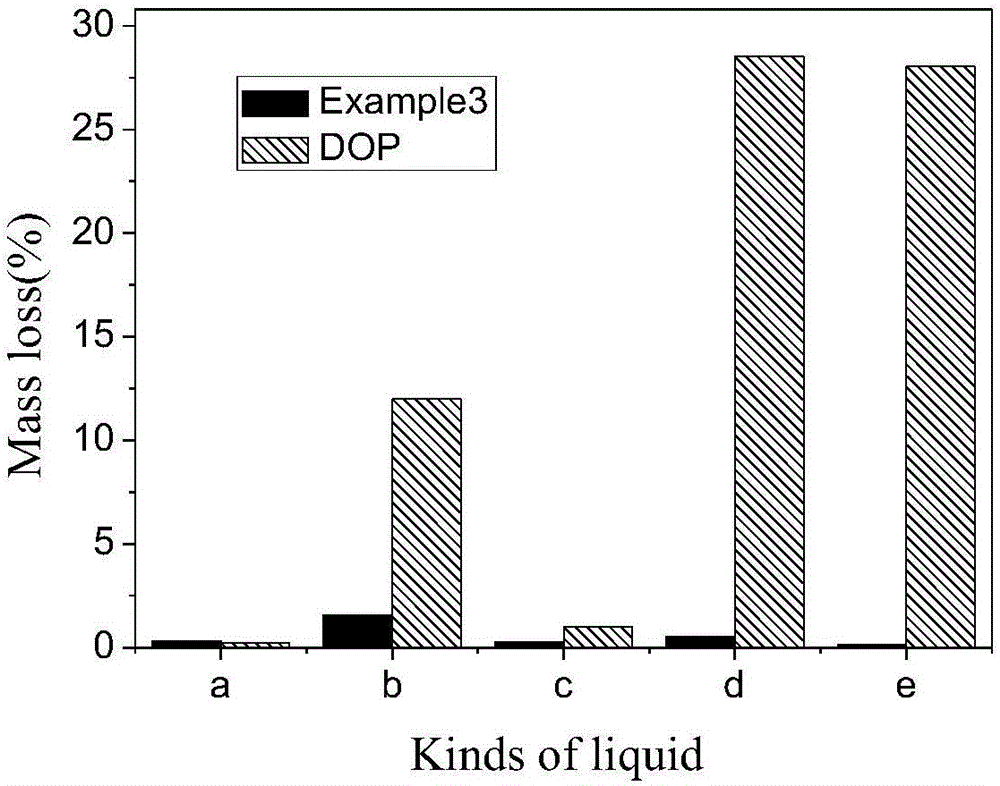

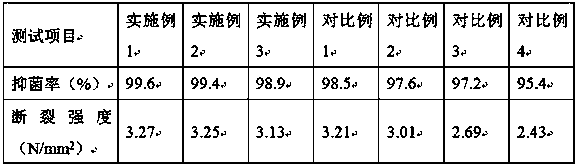

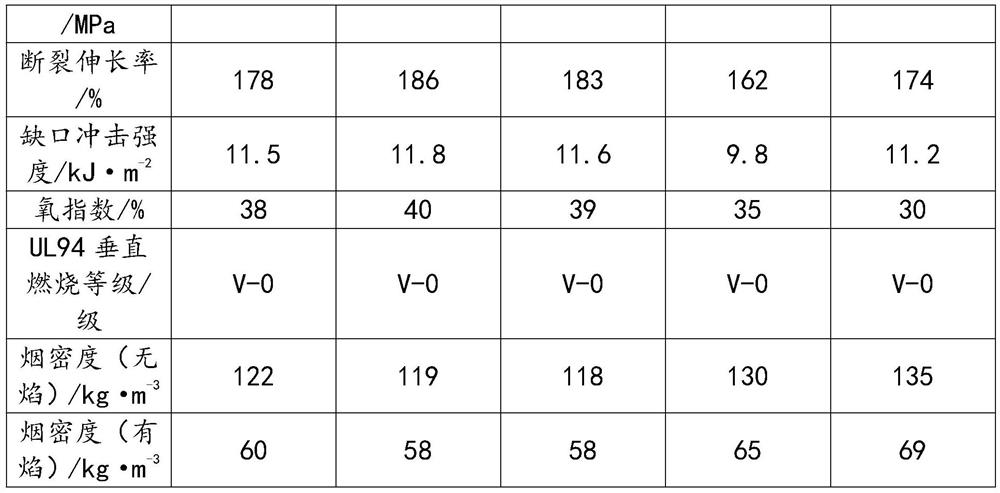

PVC sheet material utilizing novel polyester as plasticizer and preparation method therefor

The invention provides a PVC sheet material utilizing novel polyester as a plasticizer and a preparation method, and relates to a novel PVC material and a preparation method thereof. The PVC sheet material comprises the following components in parts by weight: 100 parts of PVC, 25-50 parts of plasticizer and 4-8 parts of heat stabilizer. The novel polyester is copolyester of succinic acid, itaconic sodium hypophosphite and 1,6-hexanediol, has a long-chain macromolecule structure, and has a large entanglement function with a PVC molecular chain, the solvent extraction resistance of the novel polyester is far better than that of other traditional plasticizer, and the molecular structure of the novel polyester further has a phosphate group, so that the novel polyester also has great flame resistance; and more importantly, the plasticizing efficiency of the novel polyester at low content is higher than that of DOP. The PVC sheet material is formed by extruding and injection molding at 170 DEG C through a mini screw extruder and a mini injection molding machine. According to the PVC sheet material utilizing the novel polyester as the plasticizer and the preparation method, products are nontoxic, migration-resisting and anti-aging, have excellent flame resistance and plasticizing performance, and have excellent application prospect; and the preparation method is simple, the operation is convenient, and practicability is strong.

Owner:QINGDAO UNIV OF SCI & TECH

Antibacterial fabric and preparation method thereof

The invention discloses an antibacterial fabric and a preparation method thereof and belongs to the technical field of textile production. The hyperbranched polymer obtained by modifying a quaternaryammonium salt structure is used for antibacterial finishing of fabrics, on one hand, the hyperbranched polymer has high solubility, the washing resistance is improved; on the other hand, long-chain alkyl is introduced in the substitution process, the cytotoxicity is reduced, and a hydrophobic group and a hydrophilic group deeply penetrate into lipid layers and protein layers of bacterial cells respectively, so that the antibacterial performance is enhanced. After an epoxy group and a hydroxyl group of starch produce etherification action, the long-acting antibacterial property is formed, the performance of the fabric is improved, the plasticizing effect on the fiber is achieved, the antibacterial efficiency is improved, the plasticity and entanglement performance of the fiber are improved,the mechanical property and toughness of the fabric are improved, and the antibacterial efficiency is also increased. The problem is solved that an antibacterial additive in an existing antibacterialfabric is high in toxicity and has the influence on the mechanical property of the fabric itself.

Owner:常州海瑞纺织品有限公司

Environment-friendly and degradable food-grade plastic packaging film

InactiveCN109111637ALow priceRich sourcesFlexible coversWrappersFiberLinear low-density polyethylene

The invention discloses an environment-friendly and degradable food-grade plastic packaging film. The environment-friendly and degradable food-grade plastic packaging film is prepared from the following raw materials in parts by weight: 65 to 76 parts of modified linear low-density polyethylene particles, 25 to 35 parts of plant starch, 7 to 14 parts of sarcandra glabra fibers, 8 to 18 parts of filling master batch, 3 to 6 parts of a dispersant, 2 to 4 parts of a coupling agent, 2 to 6 parts of a compound plant antibacterial agent, 3 to 5 parts of an amphoteric surfactant, 5 to 7 parts of graphene oxide, 3 to 5 parts of xanthan gum, 1 to 3 parts of cellulose acetate, 2 to 4 parts of a light degradation agent, 1 to 3 parts of an ultraviolet absorbent, 2 to 4 parts of coconut oil, 1 to 3 parts of glycerol, 1 to 3 parts of prunus humilis bunge fibers, 1 to 3 parts of a waterproof agent and 2 to 4 parts of an antioxidant. According to the environment-friendly and degradable food-grade plastic packaging film, the plant starch and the sarcandra glabra fibers have abundant sources and a cheap price, and are environmentally friendly; the prepared plastic thin film has the advantages of high strength, low production cost, biodegradability, antistatic performance, oxidization resistance and ultraviolet resistance, and the problem of white pollution can be alleviated.

Owner:桐城市强峰包装有限公司

Low-smoke halogen-free fireproof shielding control cable

PendingCN111793312AEasy to stretchEnhanced interactionPlastic/resin/waxes insulatorsInsulated cablesPolymer scienceElectrical conductor

The invention discloses a low-smoke halogen-free fireproof shielding control cable. The cable comprises a cable conductor of a plurality of strands of copper stranded wires, the surface of the cable conductor is covered with a fireproof sheath layer, and the fireproof sheath layer comprises the following raw materials in parts by weight: 60-70 parts of modified polyvinyl chloride resin, 8-10 partsof an ethylene-vinyl acetate copolymer, 2-3 parts of a compatilizer, 2-3 parts of a flame retardant, 0.8-1 part of an antioxidant and 1.5-2 parts of a lubricant. According to the cable, the fireproofsheath layer is adopted as a sheath layer material, the fireproof sheath layer takes the modified polyvinyl chloride resin as a polymer matrix, the polyvinyl chloride resin has flame retardance, andafter modification, the tensile property can be improved, an epoxy group can be introduced to a molecular side chain, and the binding force with a flame retardant is improved; and the self-made flameretardant is added into the raw materials of the fireproof sheath layer, and the flame retardant is a phosphonate compound and can exert a certain plasticizing effect, so that the fireproof sheath layer is endowed with good low-smoke fire resistance and mechanical properties.

Owner:ANHUI ZHONGTONG CABLE TECH

Hydrophobic furniture coating and preparation method thereof

InactiveCN105969116AIncrease crosslink densityHigh tensile strengthPolyester coatingsTriterpenoid saponinHydroxymethyl

The invention discloses a hydrophobic furniture coating, which is composed of the following raw materials (by weight): 1-2 parts of polyvinylidene fluoride, 4-6 parts of 2-perfluoroalkyl ethanol, 10-12 parts of tung oil, 0.06-0.07 part of sodium hydroxide, 3-4 parts of methanol, 0.1-0.2 part of perfluorosulfonate resin, 6-8 parts of acetic acid, 10-15 parts of 26-30% hydrogen peroxide, 10-17 parts of tetraethyl orthosilicate, 0.1-0.2 part of Y-chloropropyltrimethoxysilane, 70-80 parts of unsaturated polyester resin, 0.6-1 part of methylethyl ketone peroxide, 0.8-1 part of N-hydroxymethyl acrylamide, 2-3 parts of Salatrim, 16-20 parts of wollastonite powder, 0.7-1 part of triterpenoid saponin, 0.1-0.3 part of stannous sulfate and 1-2 parts of tetrapolyricinoleate. By using perfluorosulfonate resin as a catalyst and adding 2-perfluoroalkyl ethanol, hydrophobicity of a film of the finished product is effectively raised.

Owner:丁顺

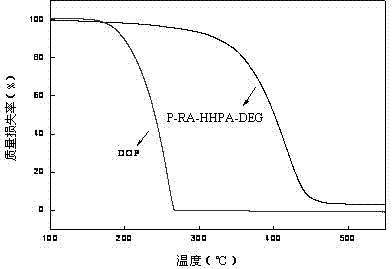

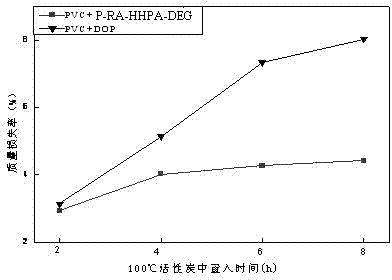

A kind of preparation method of castor oil-based polyester used as pvc plasticizer

The invention discloses a method for preparing caster oil-based polyester serving as a PVC (Polyvinyl Chloride) plasticizer, belonging to the technical field of chemical synthesis. The method comprises the following steps: preparing caster oil-based dicarboxylic acid by reacting a down-stream product, namely, ricinoleic acid of low-price bio-based raw caster oil, dihydric anhydride and dihydric alcohol serving as raw materials in two steps: preparing caster oil-based dicarboxylic acid by using ricinoleic acid and dihydric anhydride, and carrying out a polyesterification reaction on the caster oil-based dicarboxylic acid and the dihydric alcohol in the coexistence of a catalyst and a water-carrying agent; and distilling under reduced pressure to obtain the caster oil-based polyester PVC plasticizer. A PVC plastic test piece is prepared by treating the caster oil-based polyester PVC plasticizer, PVC resin and a thermal stabilizer according to a certain formula through a solvent film casting method. The test piece is soft, and is equivalent to a PVC plastic piece plasticized by dioctyl phthalate (DOP) in the transparency under the same condition. The raw material is caster oil-based, recyclable, low in price and independent of petroleum, a preparation process is simple, and three wastes are not produced. The product is non-toxic, environment-friendly, resistant to migration, and superior in plasticizing performance, and has a good application prospect.

Owner:JIANGNAN UNIV

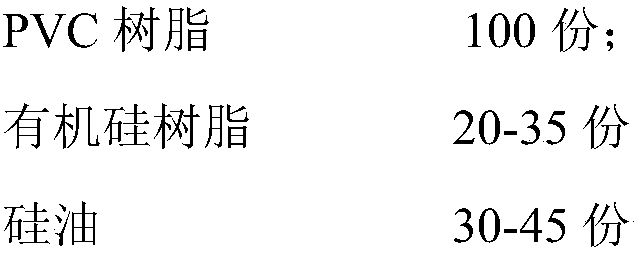

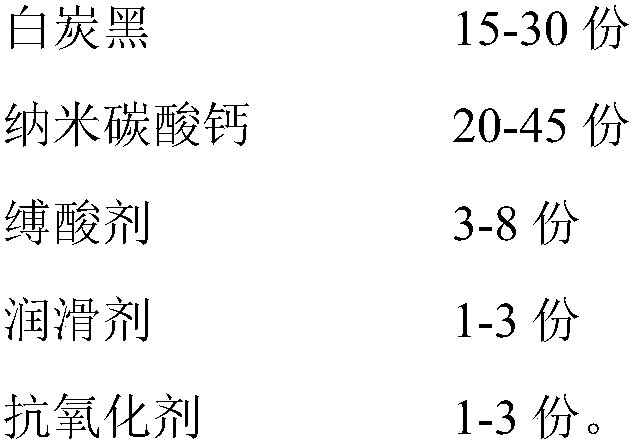

Low temperature-resistant PVC (Polyvinyl Chloride) cable material

InactiveCN108707298AWith high and low temperature resistanceWith electrical insulationPlastic/resin/waxes insulatorsAntioxidantPolyvinyl chloride

The invention relates to a cable material, in particular to a low temperature-resistant PVC (Polyvinyl Chloride) cable material and a preparation method thereof. The low temperature-resistant PVC cable material is prepared from the following components in parts by weight: 100 parts of PVC resin, 20 to 35 parts of organosilicone resin, 30 to 45 parts of silicone oil, 15 to 30 parts of white carbonblack, 20 to 45 parts of nano calcium carbonate, 3 to 8 parts of acid-binding agent, 1 to 3 parts of lubricating agent and 1 to 3 parts of antioxidant. The low temperature-resistant PVC cable materialdisclosed by the invention has the following beneficial effects that (1) through a plasticizing effect of the organosilicone resin and the silicone oil, low temperature resistance of the low temperature-resistant PVC cable material can be effectively improved; (2) a formula and a preparation technology of the low temperature-resistant PVC cable material are simple, are low in cost, are capable ofproducing without changing existing equipment and are suitable for large-scale production; (3) the obtained low temperature-resistant PVC cable material also is good in mechanical property, weather fastness and flame resistance.

Owner:ZHEJIANG WELLSCOM PLASTIC CO LTD

Plastic bag prepared from modified sorghum straw

The invention discloses a plastic bag prepared from modified sorghum straw. The plastic bag is prepared from linear low density polyethylene, the modified sorghum straw, alpha-methylstyrene cyclic dimer, glycerol monooleate, starch, rosin, acrylamide, C9 petroleum resin, biphenol acrylate and polyvinyl alcohol. According to the plastic bag prepared from the modified sorghum straw, the sorghum straw resources can be well utilized, the problem of poor compatibility of the sorghum straw and plastic is solved, and the prepared plastic bag is greatly improved on the performance in all aspects and has the advantages of being low in energy consumption, small in pollution and low in protection cost. The longitudinal tensile strength of the plastic bag can reach 16.7 MPa, and the transverse tensile strength of the plastic bag can reach 15.5 MPa. The plastic bag is bright in gloss, good in transparency, high in bearing capability and capable of meeting the requirements of consumers for containing more articles and using repeatedly.

Owner:BENGBU WEIGUANG PLASTIC PRODS

Environment-friendly degradable plastic bag

InactiveCN109337162AImprove thermal stabilityImprove antioxidant capacityLow-density polyethyleneThermal ageing

The invention discloses an environment-friendly degradable plastic bag. The environment-friendly degradable plastic bag comprises the following components of 30-55 parts of low density polyethylene, 20-26 parts of polyvinyl alcohol resin, 3-5 parts of butantriol, 2-6 parts of photocoupler, 5-10 parts of a degradation accelerator, 2-7 parts of cellulose acetate, 1-10 parts of diatomite, 1-4 parts of a chelating agent, 2-5 parts of an emulsifying agent and 3-7 parts of a self-collapsing agent in parts by weight. The environment-friendly degradable plastic bag, disclosed by the invention, has theadvantages that cross-linking and gelation caused by thermal ageing in the plastic bag machining process can be prevented by adding the photocoupler and the chelating agent to a polyethylene molded plastic system in a synergistic manner, thermostability and oxidation resistance of the prepared plastic bag can be greatly improved; a plastifying effect can also be realized; and meanwhile, as the degradation accelerator is added to the material, the prepared plastic bag obtains excellent biological degradability.

Owner:苏州起亚塑业有限公司

Tung oil modified furniture coating and preparation method thereof

InactiveCN105969129AIncrease crosslink densityHigh tensile strengthOrganic chemistryPolyester coatingsAcetic acidMethyl ethyl ketone peroxide

The invention discloses a tung oil modified furniture coating, which is composed of the following raw materials (by weight): 10-12 parts of tung oil, 0.06-0.07 part of sodium hydroxide, 3-4 parts of methanol, 0.1-0.2 part of perfluorosulfonate resin, 6-8 parts of acetic acid, 10-15 parts of 26-30% hydrogen peroxide, 10-17 parts of tetraethyl orthosilicate, 0.1-0.2 part of Y-chloropropyltrimethoxysilane, 70-80 parts of unsaturated polyester resin, 0.6-1 part of methyl ethyl ketone peroxide and 18-20 parts of vermiculite power. Epoxidized methyl eleostearate has aliphatic long-chain hydrocarbon which can have a plastifying effect in resin and can enhance flexibility of unsaturated polyester resin.

Owner:刘夏南

Plastic bag prepared from modified waste tire rubber powder

InactiveCN105885195AGood compatibilityImprove surface propertiesLow-density polyethyleneLinear low-density polyethylene

The invention discloses a plastic bag prepared from modified waste tire rubber powder. The plastic bag is prepared from linear low density polyethylene, the modified waste tire rubber powder, alpha-methylstyrene cyclic dimer, polyacrylamide, starch, rosin, acrylamide, C9 petroleum resin, biphenol acrylate and polyvinyl alcohol. According to the plastic bag prepared from the modified waste tire rubber powder, the waste tire resources can be well utilized, the natural environment is protected, the resource utilization rate is increased, and the plastic bag has the advantages of being low in energy consumption, small in pollution and low in protection cost. The longitudinal tensile strength of the plastic bag can reach 17.1 MPa, and the transverse tensile strength of the plastic bag can reach 16.2 MPa. The plastic bag is bright in gloss, good in transparency, high in bearing capability and capable of meeting the requirements of consumers for containing more articles and using repeatedly.

Owner:BENGBU WEIGUANG PLASTIC PRODS

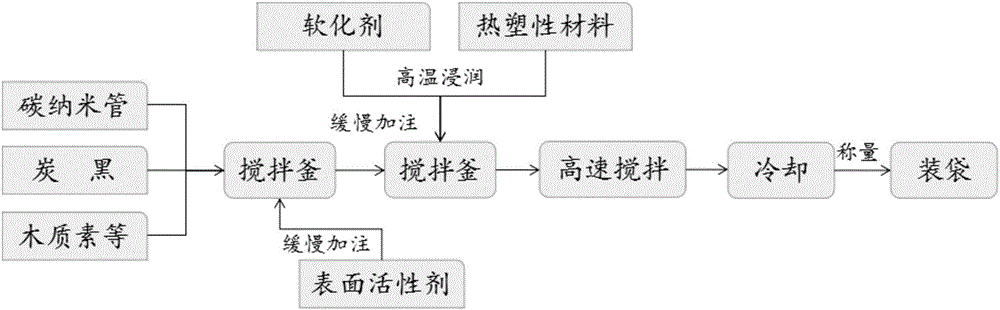

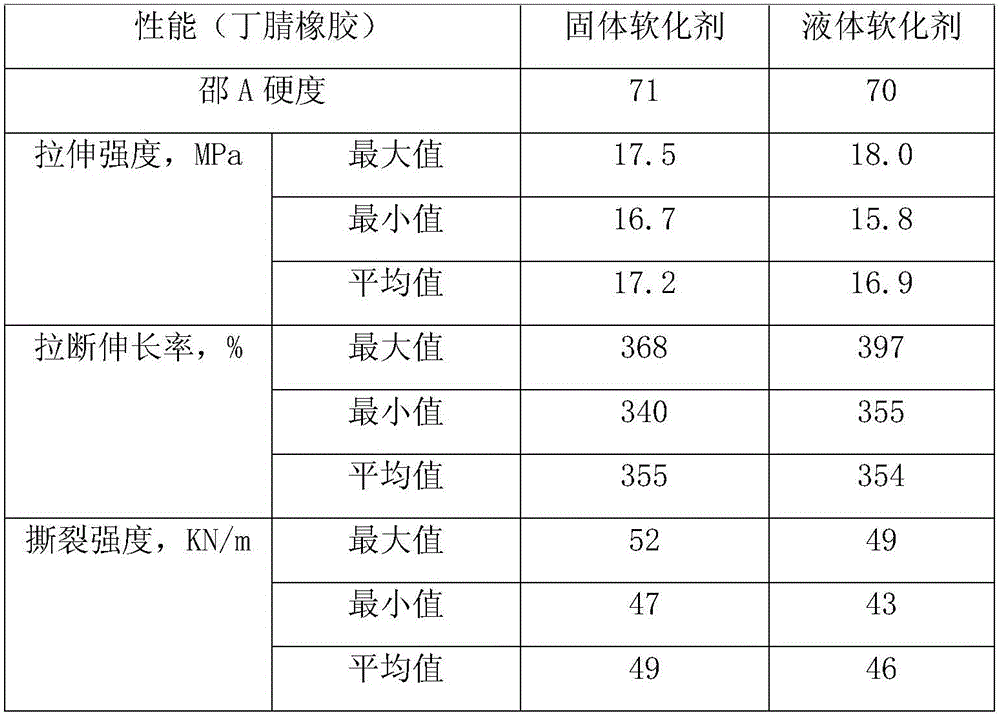

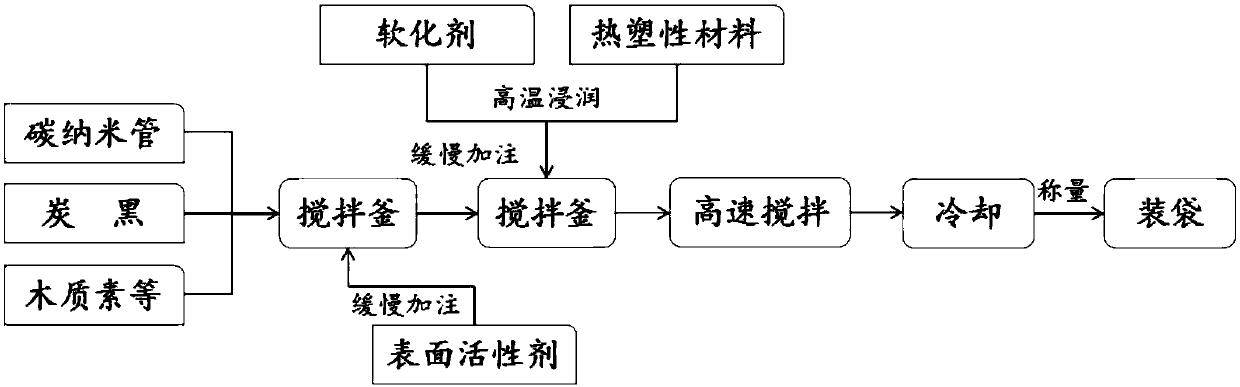

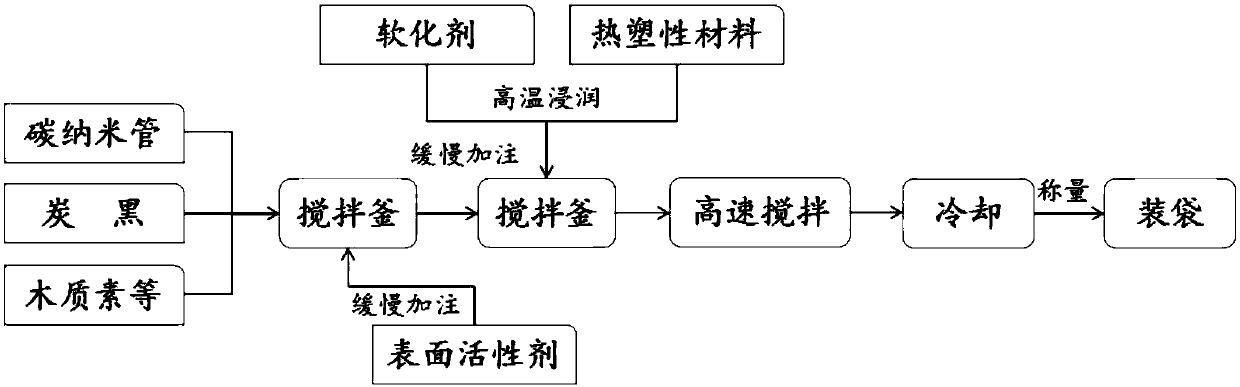

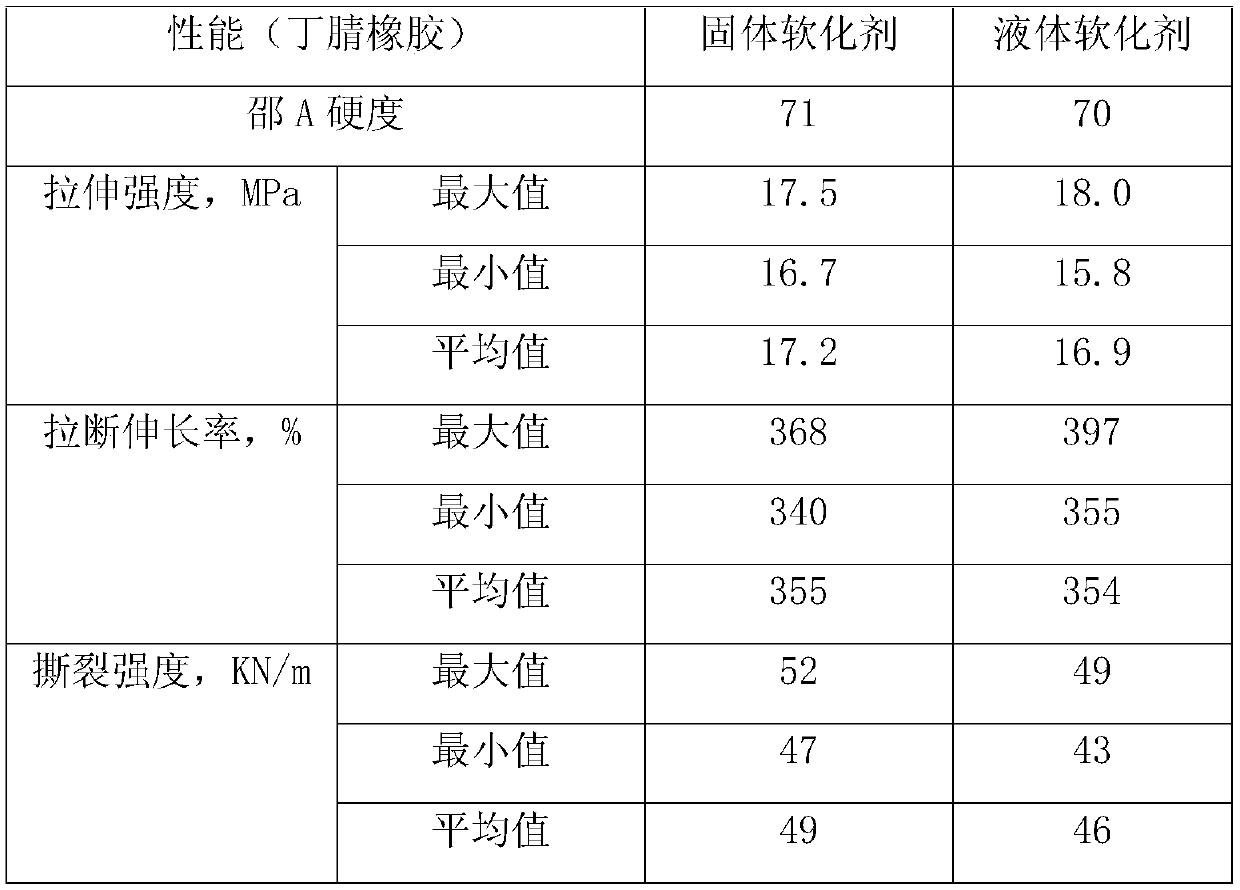

Solid softener for rubber and preparation method

The invention discloses a solid softener for rubber and a preparation method. The solid softener is prepared from a carbon nano tube, high-adsorption-performance packing, a surfactant, a thermoplastic macromolecular material and various softeners for rubber. Compared with a common liquid softener, the solid softener for rubber has the advantages that the rubber mixing time is shortened by 20 percent, the rubber mixing uniformity is obviously improved, and the comprehensive mechanical property of mixed rubber is obviously improved. The method is simple, efficient, environmental-friendly and pollution-free; a prepared product is convenient to transport, accurately weighed, quickly added and high in dispersity; the phenomena of escaping, popping out, leakage and dripping of the common liquid softener are avoided; moreover, the carbon nano tube and the high-adsorption-performance packing are also reinforcers capable of enhancing and improving the mechanical property of the rubber; the added thermoplastic macromolecular material is plasticized at relatively high temperature and then is wetted with the softener; and after being cooled, the thermoplastic macromolecular material can adsorb part of the softener, so that the solid powdered softener can still keep no agglomeration under a long-term gravity state.

Owner:QINGDAO UNIV OF SCI & TECH

A kind of hemostatic material and preparation method thereof

ActiveCN107261193BRegulation of degradation rateImprove hydrophilicityPharmaceutical delivery mechanismAbsorbent padsNasal passagesPolyvinyl alcohol

Owner:BEIJING TONGREN HOSPITAL AFFILIATED TO CAPITAL MEDICAL UNIV

A kind of superfine bainitic bridge cable steel and preparation method thereof

The invention discloses ultrafine bainite bridge cable steel and a preparing method thereof, and belongs to wires for bridge cables and production thereof. The thermo-mechanical treatment + isothermalquenching technology is adopted for obtaining the cable steel; pre-deformation and low-temperature bainite isothermality are combined, refining technologies of microalloy refinement, controlled rolling and cooling refining, pre-deformation and low-temperature bainite isothermality are comprehensively used, an ultrafine bainite structure composed of non-carbonization bainite and retained austeniteis obtained, the tensile strength of the structure ranges from 1800 to 2100 MPa, and the ductility of the structure ranges from 12 to 20%; the preparing process of the ultrafine bainite bridge cablesteel comprises the steps of smelting, continuous casting, hot rolling, cutting, austenitizing, pre-deforming and low-temperature bainite isothermality. During pre-deforming, firstly, a cut hot-rolledwire rod is heated again to Ac3+50 DEG C to be subjected to austenitizing, heat preservation is carried out for 0.5 to 1 h, rapid cooling (the cooling speed is larger than 10 DEG C / s) to 220 to 280 DEG C is carried out, further warm rolling is carried out, the rolling reduction is 20 to 30%, then, the wire rod is put into a salt bath furnace at the temperature of 220 to 280 DEG C to be subjectedto isothermality treatment for 3 to 5 h, and isothermality bainite conversion is carried out; and the wire rod is taken out and subjected to air cooling to the room temperature.

Owner:UNIV OF SCI & TECH BEIJING

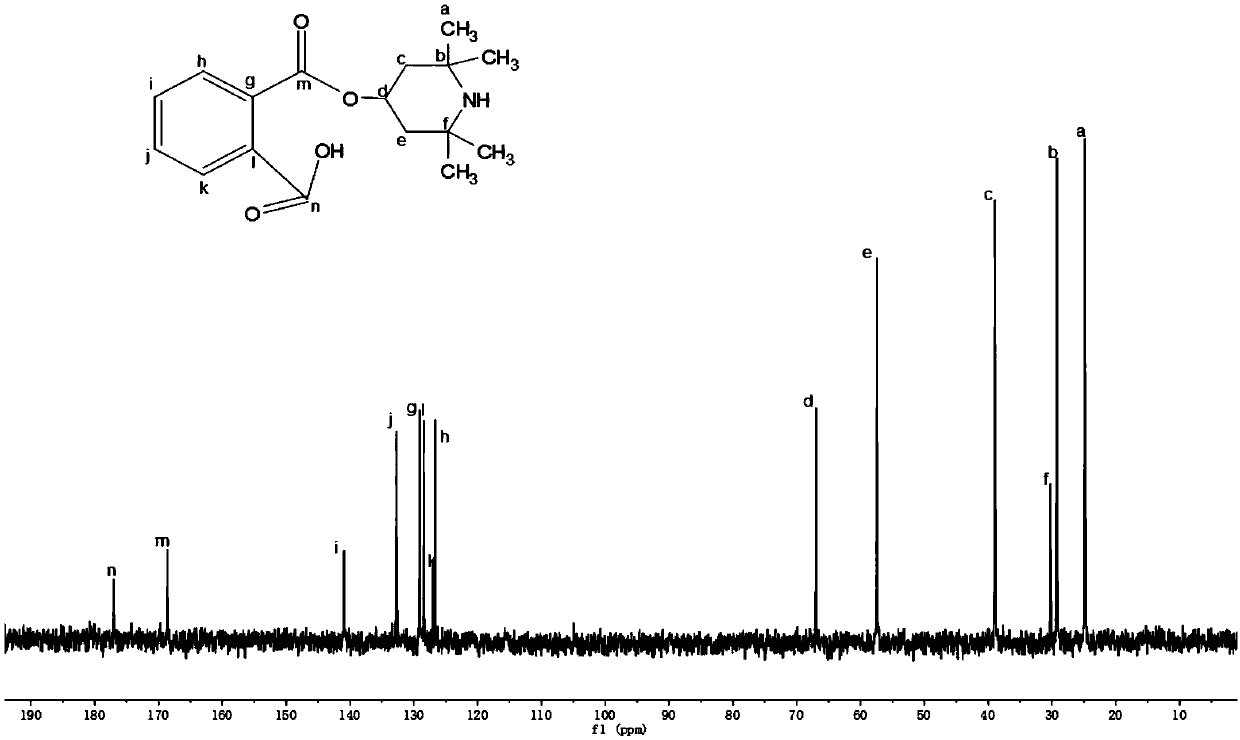

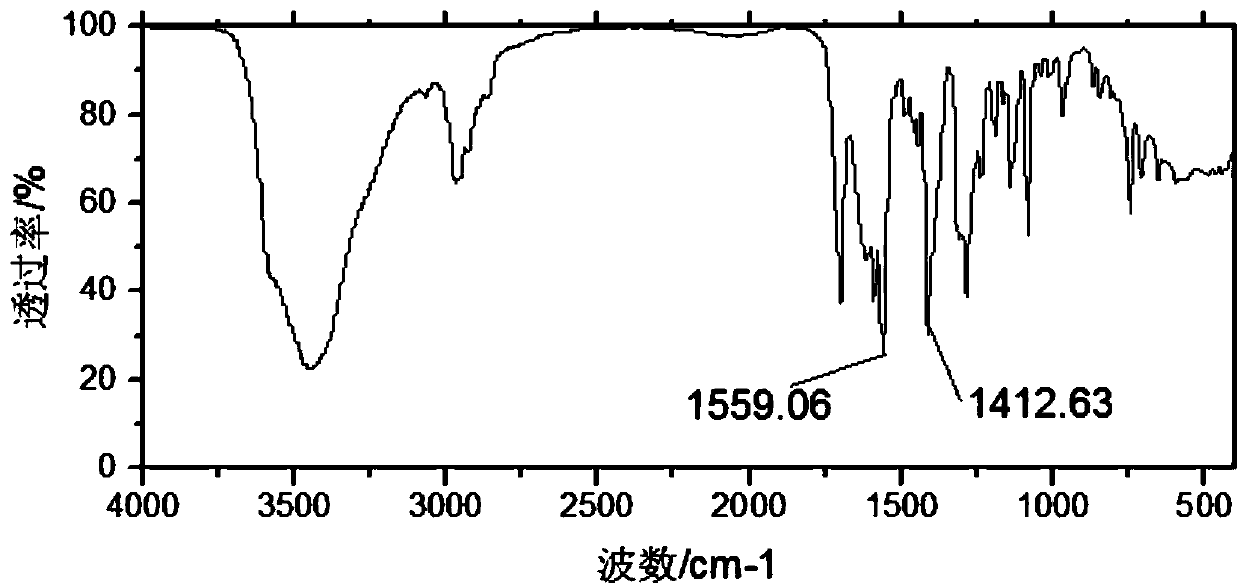

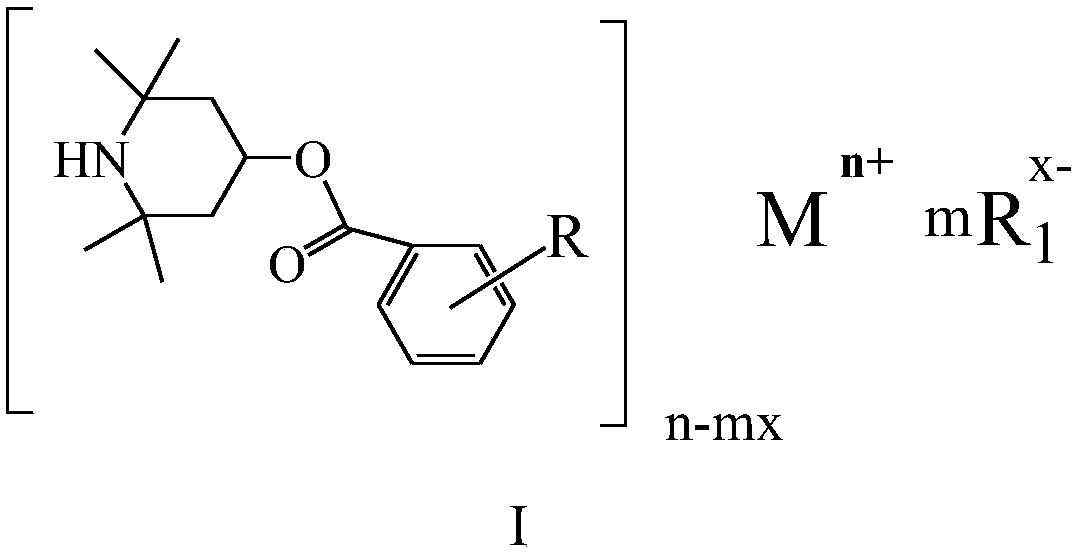

A kind of pvc stabilizer with thermal and light stability and preparation method thereof

ActiveCN106916335BImproved heat and light stabilityPlay a plasticizing effectOrganic chemistryOrganic acidStructural formula

The invention relates to a PVC stabilizer with good heat and light stability, and a preparation method thereof, and belongs to the technical field of PVC plastic assistants. The chemical structural formula of the PVC stabilizer is shown in the description; and in the formula, R is a carboxylic group, R1 is an organic acid radical, x is the valence of the R1, m is 0, 1, 2, 3, 4..., mx is less than n, M is a metal, and n is the valence of the metal. The preparation method comprises the following steps: carrying out an esterifying reaction on a phenyl diacid compound and 2,2,6,6-tetramethyl-4-piperidinol to generate a phenyl diacid ester of mono(tetramethylpiperidine), reacting the phenyl diacid ester of mono(tetramethylpiperidine) with the R1 acid and sodium hydroxide to generate a sodium salt, adding metal salt, and carrying out a metathesis reaction to obtain the target stabilizer, or directly reacting the phenyl diacid ester of mono(tetramethylpiperidine) with metal hydroxide or metal oxide at a high temperature to obtain the target stabilizer. The PVC stabilizer has good heat stability and good light stability, and the preparation method has the advantages of simplicity, easiness in condition control, good reappearance, and good development potential and application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Solid softener for rubber and preparation method thereof

The invention discloses a solid softener for rubber and a preparation method. The solid softener is prepared from a carbon nano tube, high-adsorption-performance packing, a surfactant, a thermoplastic macromolecular material and various softeners for rubber. Compared with a common liquid softener, the solid softener for rubber has the advantages that the rubber mixing time is shortened by 20 percent, the rubber mixing uniformity is obviously improved, and the comprehensive mechanical property of mixed rubber is obviously improved. The method is simple, efficient, environmental-friendly and pollution-free; a prepared product is convenient to transport, accurately weighed, quickly added and high in dispersity; the phenomena of escaping, popping out, leakage and dripping of the common liquid softener are avoided; moreover, the carbon nano tube and the high-adsorption-performance packing are also reinforcers capable of enhancing and improving the mechanical property of the rubber; the added thermoplastic macromolecular material is plasticized at relatively high temperature and then is wetted with the softener; and after being cooled, the thermoplastic macromolecular material can adsorb part of the softener, so that the solid powdered softener can still keep no agglomeration under a long-term gravity state.

Owner:QINGDAO UNIV OF SCI & TECH

Electron radiation cross-linked elastomer foam for water pump sealing and preparation method thereof

The invention belongs to the field of high polymer materials, and particularly relates to a preparation method of electron radiation cross-linked elastomer foam for water pump sealing. The preparationmethod has the advantages of simple production technique and wide raw material sources; and chlorinated polypropylene, polyvinyl ether polymer and polyvinyl acetylene resin are used as main raw materials, a foaming agent and protein colloids are used as auxiliary materials and uniformly mixed to form slurry, and pre-foaming, oil-bath foaming and dynamic sulfurization are successively conducted toobtain a high-molecular closed-cell foam material which has a smooth and flat surface, uniform and fine internal cells, low water absorption and good sound insulation, heat insulation, shock absorption performances and mechanical properties.

Owner:ANHUI JINWAN PUMP TECH CO LTD

A kind of solid electrolyte and its preparation method and application

ActiveCN110048156BImprove mechanical propertiesImprove conductivityFuel and secondary cellsFinal product manufactureSolid state electrolyteMetallic lithium

The invention discloses a solid electrolyte and its preparation method and application. The solid electrolyte includes a polymer phase, ceramic electrolyte and lithium salt dispersed in the polymer phase; the polymer phase is a fluorine-containing polymer-polyacrylate copolymer. The preparation method includes: 1) mixing the fluorine-containing polymer with an organic solvent, and reacting at 100-150° C. to obtain a modified fluorine-containing polymer; 2) preparing the modified fluorine-containing polymer prepared in step 1), ceramic electrolyte, Lithium salts, acrylate monomers and initiators are mixed and polymerized in an inert atmosphere to obtain a solid electrolyte. The solid electrolyte disclosed by the invention has high mechanical strength combined with toughness, high lithium ion conductivity, excellent interfacial compatibility with metal lithium negative electrode and oxide positive electrode respectively, and high chemical / electrochemical stability , can be applied in lithium metal batteries, lithium-air batteries and lithium-sulfur batteries.

Owner:ZHEJIANG UNIV

Flat paint for furniture and preparation method thereof

InactiveCN105969121AIncrease crosslink densityImprove film forming performanceOrganic chemistryPolyester coatingsTetraethyl orthosilicateEther

The invention discloses a flat paint for furniture. The flat paint is composed of the following raw materials (by weight): 1.4-3 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 0.7-2 parts of PTMEG, 0.8-2 parts of p-toluenesulfonamide, 10-12 parts of tung oil, 0.06-0.07 part of sodium hydroxide, 3-4 parts of methanol, 0.1-0.2 part of perfluorosulfonate resin, 6-8 parts of acetic acid, 10-15 parts of 26-30% hydrogen peroxide, 10-17 parts of tetraethyl orthosilicate, 0.1-0.2 part of Y-chloropropyltrimethoxysilane, 70-80 parts of unsaturated polyester resin, 0.6-1 part of methylethyl ketone peroxide, 15-20 parts of barite powder, 1-2 parts of naphthenic soap, 0.8-2.2 parts of lauryl alcohol phosphoric acid ester potassium, 1-2 parts of phenylimidazoline, 0.8-1 part of calcium alginate, 3-5 parts of titanium dioxide and 0.2-0.4 part of polyoxyethylene octylphenol ether. By adding titanium dioxide and barite powder into the paint, effective effects can be achieved, and decorative performance of a film is enhanced.

Owner:刘辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com