A kind of pvc stabilizer with thermal and light stability and preparation method thereof

A heat stabilizer and light stabilizer technology, applied in the direction of organic chemistry, can solve the problems of product color change, mechanical property decline, molecular chain breakage, etc., and achieve the effect of convenient operation, improved heat and light stability, and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

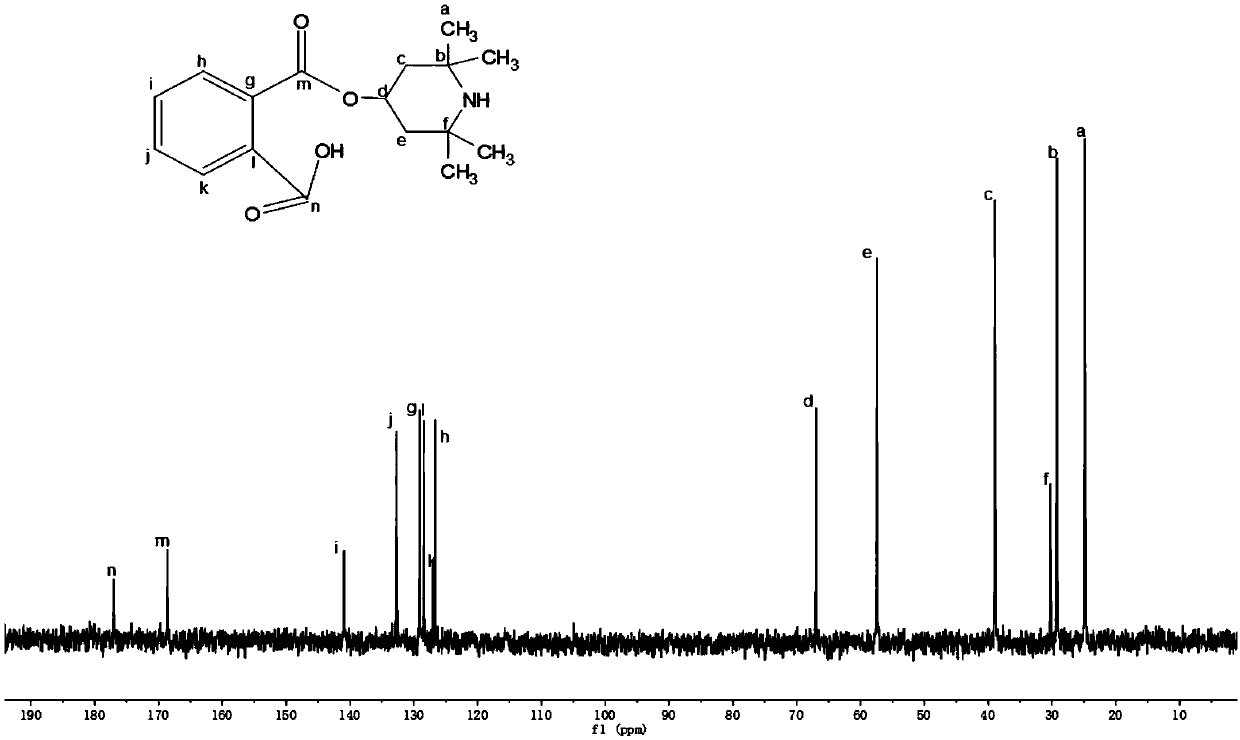

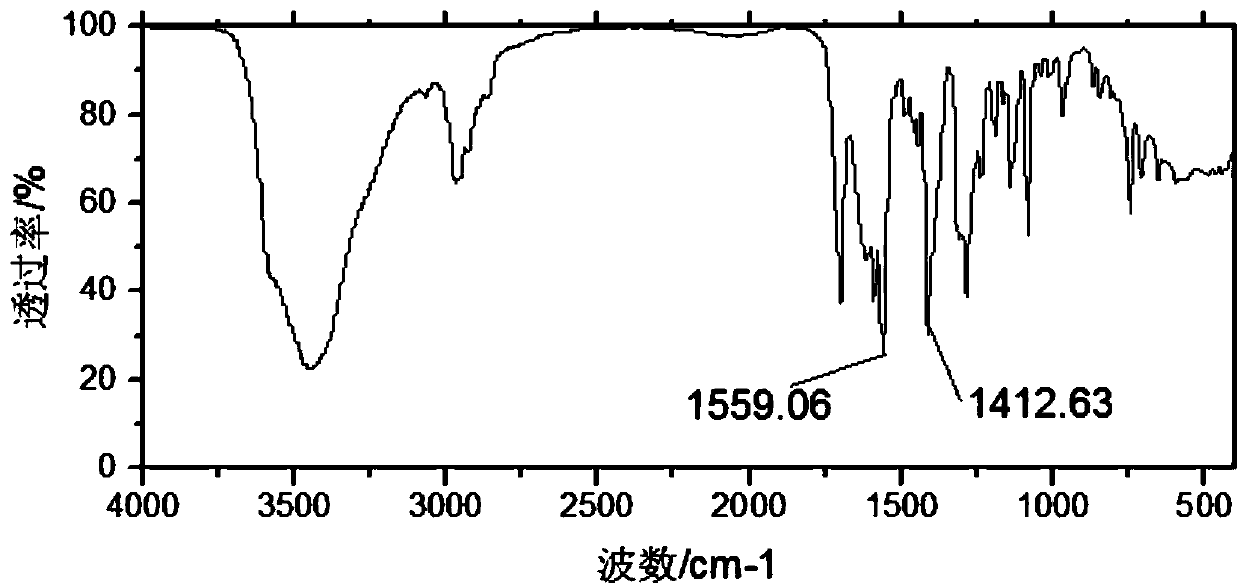

[0034] Weigh 8.88g (0.06mol) of phthalic anhydride into a 150ml three-neck flask, add an appropriate amount of solvent, equip with a stirring bar and a thermometer, and place it in a water bath. 8 g (0.05 mol) of 2,2,6,6-tetramethyl-4-piperidinol was added in batches within 20 min to 30 min, and the temperature was continuously raised to 50° C., followed by a constant temperature reaction for 1 h. The layers were allowed to stand, filtered, and finally vacuum-dried at 70°C. A white solid powder was obtained, which was monotetramethylpiperidinol phthalate.

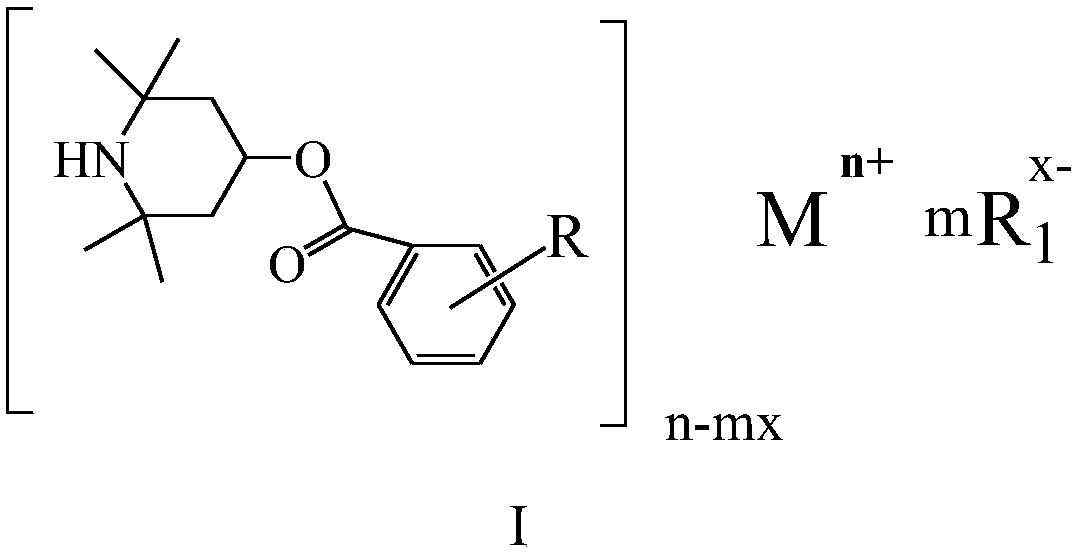

[0035] Add 1g (3.3mmol) monotetramethylpiperidinol phthalate, 0.132g (3.3mmol) sodium hydroxide and 10ml methanol solution in a 100ml single-necked flask, add a magnetic sub-flask, and at room temperature, make o-phthalic acid Monotetramethylpiperidinol dicarboxylate is dissolved in methanol by reaction with sodium hydroxide. After the dissolution is complete, add 0.183g (1.65mmol) of calcium chloride, react for 1h, filte...

Embodiment 2

[0037] Add 0.915g (3mmol) of monotetramethylpiperidinol phthalate obtained in Example 1 in a 100ml single-necked flask, then add 0.12g (3mmol) sodium hydroxide and 15ml tetrahydrofuran solution, add magnetic sub-stir , At room temperature, slowly add deionized water to make monotetramethylpiperidinol phthalate react with sodium hydroxide and dissolve in a mixed solvent of tetrahydrofuran and water. After complete dissolution, add 0.37g (1 mmol) heptahydrate and lanthanum chloride, react for 1 hour, filter, and dry to obtain a white solid, which is monotetramethylpiperidinol phthalate lanthanum salt.

Embodiment 3

[0039]In a 100ml single-necked flask, add 1.22g (4mmol) of monotetramethylpiperidinyl phthalate obtained in Example 1, then add 0.16g (4mmol) sodium hydroxide and 15ml tetrahydrofuran solution, add a magnet and stir , At room temperature, slowly add deionized water to make monotetramethylpiperidinol phthalate react with sodium hydroxide and dissolve in a mixed solvent of tetrahydrofuran and water. After the dissolution is complete, add 0.37g (1 mmol) heptahydrate and cerium chloride, react for 1h, filter, and dry to obtain a yellow solid, which is monotetramethylpiperidinol phthalate cerium salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com