PVC sheet material utilizing novel polyester as plasticizer and preparation method therefor

A technology of plasticizer and PVC pipe, which is applied in the field of PVC sheet and its preparation, can solve the problems of low environmental friendliness, and achieve the effects of simple preparation method, convenient operation and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

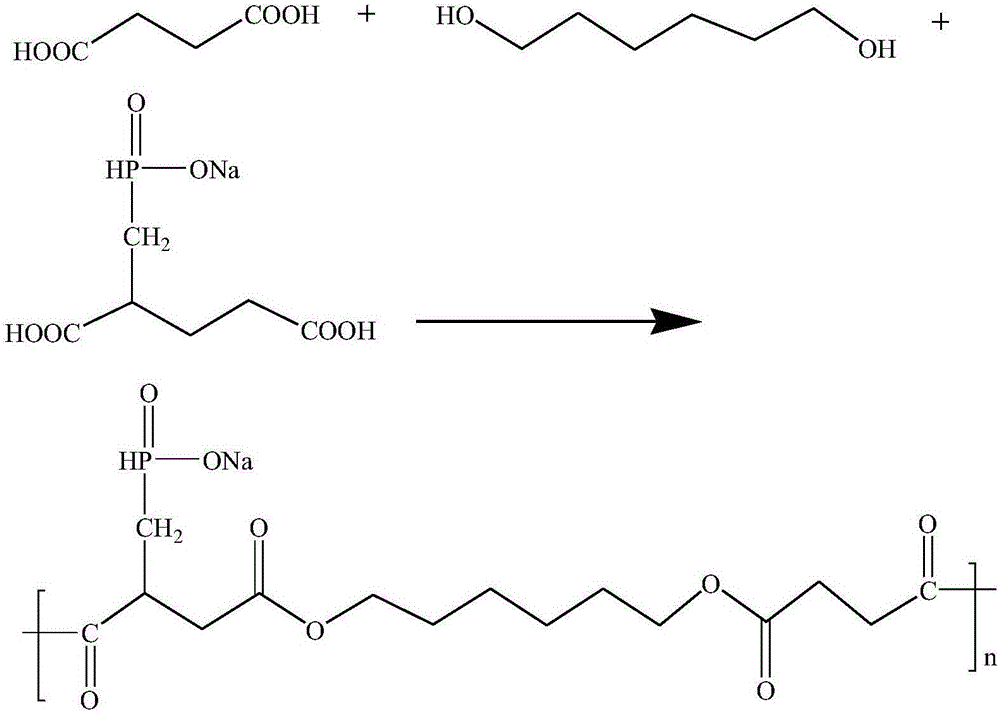

Method used

Image

Examples

Embodiment 1

[0034] Preparation of sodium hypophosphite itaconate: add itaconic acid and sodium hypophosphite in a four-neck flask according to the molar ratio of 1:1, control the temperature at 70°C-80°C, react for 4 hours, and carry out with water and ethanol (1mol:5mol) Purify and dry to obtain sodium itaconate hypophosphite. Add sodium itaconate hypophosphite, succinic acid, and 1,6-hexanediol into a four-necked flask, wherein the molar ratio of sodium itaconate hypophosphite, succinic acid, and 1,6-hexanediol is 0.1:0.9:1.05 The amount of catalyst titanium silicon molecular sieve added is 1.0% of the total mass of sodium itaconate hypophosphite, succinic acid and 1,6 hexanediol; mix the above raw materials, slowly raise the temperature to 175°C under the protection of nitrogen, and react for 3 hours , stop the reaction, cool to room temperature, that is, the new type Polyester plasticizer.

[0035] Put PVC, plasticizer and heat stabilizer into high-speed universal pulverizer and ca...

Embodiment 2

[0038]Add sodium itaconate hypophosphite, succinic acid, and 1,6-hexanediol into a four-necked flask, wherein the molar ratio of sodium itaconate hypophosphite, succinic acid, and 1,6-hexanediol is 0.1:0.9:1.2 The amount of catalyst titanium silicon molecular sieve added is 1.0% of the total mass of sodium itaconate hypophosphite, succinic acid and 1,6 hexanediol; mix the above raw materials, slowly raise the temperature to 175°C under the protection of nitrogen, and react for 3 hours , stop the reaction, cool to room temperature, that is, the new type Polyester plasticizer.

[0039] Put PVC, plasticizer and heat stabilizer into high-speed universal pulverizer and carry out blending, wherein PVC 100 parts, plasticizer 50 parts, heat stabilizer 8 parts. Heat the micro-screw extruder and micro-injection molding machine to 170°C, put the raw materials mixed with a high-speed universal pulverizer into the micro-screw extruder, the speed is 20r / min, the mixing time is 3min, and t...

Embodiment 3

[0042] Add sodium itaconate hypophosphite, succinic acid, and 1,6-hexanediol into a four-neck flask, wherein the molar ratio of sodium itaconate hypophosphite, succinic acid, and 1,6-hexanediol is 0.2:0.8:1.5 The amount of catalyst titanium silicon molecular sieve added is 1.0% of the total mass of sodium itaconate hypophosphite, succinic acid and 1,6 hexanediol; mix the above raw materials, slowly raise the temperature to 175°C under the protection of nitrogen, and react for 3 hours , stop the reaction, cool to room temperature, that is, the new type Polyester plasticizer.

[0043] Put PVC, plasticizer and heat stabilizer into high-speed universal pulverizer and carry out blending, wherein 100 parts of PVC, 45 parts of plasticizers, 6 parts of heat stabilizers. Heat the micro-screw extruder and micro-injection molding machine to 170°C, put the raw materials mixed with a high-speed universal pulverizer into the micro-screw extruder, the speed is 20r / min, the mixing time is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com