Low-smoke halogen-free fireproof shielding control cable

A control cable, fire-resistant technology, applied in the direction of insulating cables, cables, circuits, etc., can solve problems such as poor compatibility, affecting flame retardant performance, and difficulty in uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

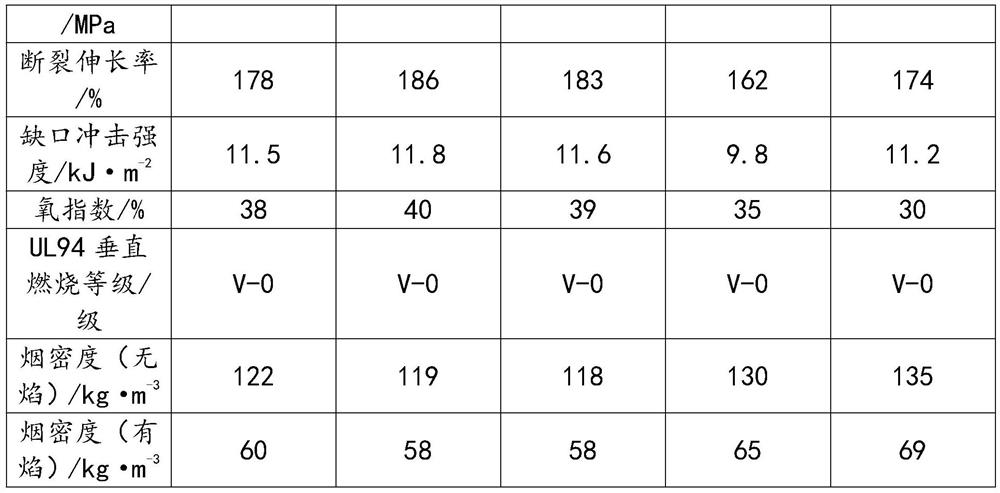

Embodiment 1

[0046] The fire-resistant sheath layer includes the following raw materials in parts by weight: 60 parts of modified polyvinyl chloride resin, 8 parts of ethylene-vinyl acetate copolymer, 2 parts of compatibilizer, 2 parts of flame retardant, 0.8 part of antioxidant, and 1.5 parts of lubricant ;

[0047] The refractory protective sheath material is made by the following steps:

[0048] Add modified polyvinyl chloride resin, ethylene-vinyl acetate copolymer, flame retardant, antioxidant and lubricant to the internal mixer in sequence according to parts by weight, and mix for 15 minutes at a temperature of 140°C , and then extruded and granulated by a single-screw extruder to obtain a refractory sheath layer material.

Embodiment 2

[0050] The fire-resistant sheath layer includes the following raw materials in parts by weight: 65 parts of modified polyvinyl chloride resin, 9 parts of ethylene-vinyl acetate copolymer, 2.5 parts of compatibilizer, 2.5 parts of flame retardant, 0.9 part of antioxidant, and 1.8 parts of lubricant ;

[0051] The refractory protective sheath material is made by the following steps:

[0052] Add modified polyvinyl chloride resin, ethylene-vinyl acetate copolymer, flame retardant, antioxidant and lubricant to the internal mixer in sequence according to parts by weight, and mix for 18 minutes at a temperature of 145°C , and then extruded and granulated by a single-screw extruder to obtain a refractory sheath layer material.

Embodiment 3

[0054] The fire-resistant sheath layer includes the following raw materials in parts by weight: 70 parts of modified polyvinyl chloride resin, 10 parts of ethylene-vinyl acetate copolymer, 3 parts of compatibilizer, 3 parts of flame retardant, 1 part of antioxidant, and 2 parts of lubricant ;

[0055] The refractory protective sheath material is made by the following steps:

[0056] Add modified polyvinyl chloride resin, ethylene-vinyl acetate copolymer, flame retardant, antioxidant and lubricant to the internal mixer in sequence according to parts by weight, and mix for 20 minutes at a temperature of 150°C , and then extruded and granulated by a single-screw extruder to obtain a refractory sheath layer material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com