A kind of preparation method of castor oil-based polyester used as pvc plasticizer

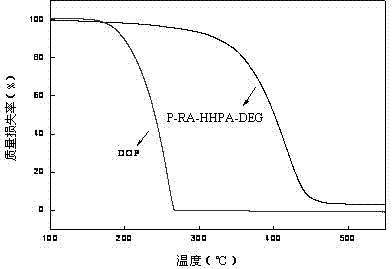

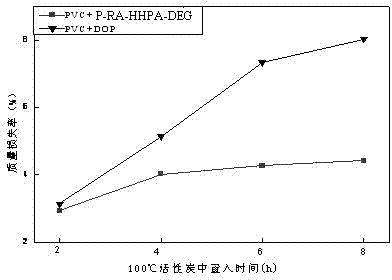

The technology of castor oil-based and plasticizer is applied in the field of preparation of castor-oil-based polyester, can solve problems such as single performance, small molecular weight, poor compatibility, etc., and achieves low cost, low energy consumption, simple and controllable reaction process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of castor oil base polyester as PVC plasticizer

[0029] (1) Preparation of castor oil-based dibasic acid: 81.61g of ricinoleic acid (RA, 0.25mol) with a concentration of 87%, 38.5g of hexahydrophthalic anhydride (HHPA, 0.25mol), Add 0.34 g of tetra-n-butyl titanate as a catalyst, control the temperature at 120° C., wait until the acid value no longer decreases, and cool to room temperature for later use.

[0030] (2) Preparation of primary castor oil-based polyester plasticizer: Weigh 37.67g of castor oil-based diacid (0.086mol) and 12.72g of diethylene glycol (DEG, 0.12mol) prepared above, Add 7.8g of cyclohexane and 0.95g of tetra-n-butyl titanate into the reactor, protect it with nitrogen, start stirring, slowly raise the temperature, and the maximum temperature does not exceed 210°C, measure the acid value every 1h, and react until the acid value Stop heating until lowered again, and cool to room temperature under the protection of nit...

Embodiment 2

[0037] A kind of preparation method of castor oil base polyester as PVC plasticizer

[0038] (1) Preparation of castor oil-based dibasic acid: Add 81.61g of ricinoleic acid (RA, 0.25mol) with a concentration of 87% and 24.5g of maleic anhydride (MA, 0.25mol) into a 250mL three-neck flask, add three 0.34 g of antimony oxide was used as the catalyst, and the temperature was controlled at 110°C. After the acid value no longer decreased, it was cooled to room temperature for later use.

[0039](2) Preparation of primary castor oil-based polyester plasticizer: Weigh 38.2g of castor oil-based diacid (0.1mol) prepared above, 18g of triethylene glycol (TEG, 0.12mol), 8.4 Add g cyclohexane and 0.75g antimony trioxide into the reactor, protect it with nitrogen gas, start stirring, slowly raise the temperature, and the maximum temperature does not exceed 210°C, measure the acid value every 1h, and react until the acid value no longer decreases , stop heating, and cool to room temperatur...

Embodiment 3

[0043] A kind of preparation method of castor oil base polyester as PVC plasticizer

[0044] (1) Preparation of castor oil-based dibasic acid: 81.61g of ricinoleic acid (RA, 0.25mol) and 38.5g of hexahydrophthalic anhydride (HHPA, 0.25mol) were added to a 250mL three-necked flask . Add 0.34 g of tetra-n-butyl titanate as a catalyst, control the temperature at 120° C., wait until the acid value no longer decreases, and cool to room temperature for later use.

[0045] (2) Preparation of primary product of castor oil-based polyester plasticizer: weigh 37.88g of castor oil-based diacid (0.086mol) and 10.8g of 1,4-butanediol (BDO, 0.12mol) prepared above , 8.7g of cyclohexane and 0.55g of tetra-n-butyl titanate were added to the reactor, protected by nitrogen gas, started to stir, slowly raised the temperature, and the maximum temperature did not exceed 210°C, measured the acid value every 1h, and reacted to the acid value Stop heating until it no longer decreases, and cool to roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com