Solid softener for rubber and preparation method

A solid softener and softener technology, applied in the field of rubber compounding agents, can solve problems such as difficult feeding, affecting filler dispersion, product performance defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

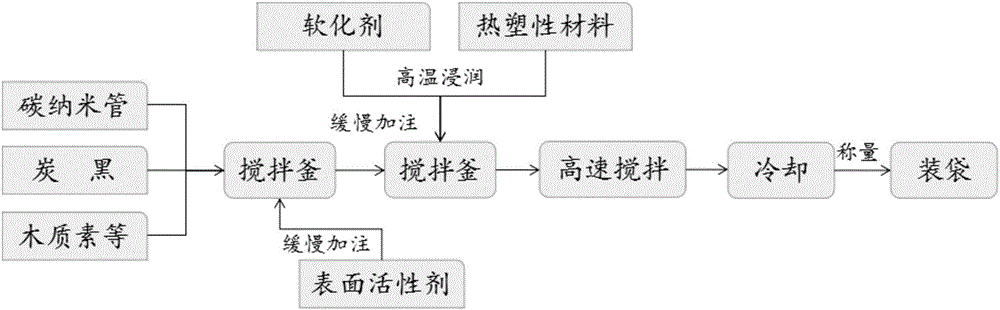

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Environment-friendly solid softener for polar rubber

[0027] The produced solid softener contains the following components (wt.%): carbon nanotubes, white carbon black, polyethylene glycol, ethylene vinyl acetate, ester polar softener MESAMOLL, and its ratio is: 8: 9:0.5:2.5:80, the specific production steps are as follows:

[0028] 1. First add the softener MESAMOLL and the thermoplastic polymer material ethylene vinyl acetate into the reaction kettle, stir at a high temperature of 100°C, discharge the material after the ethylene vinyl acetate and softener are fully infiltrated, and place it in a constant temperature tank;

[0029] 2. Add carbon nanotubes, white carbon black, and polyethylene glycol into the stirring tank according to the above ratio at room temperature, close the top cover of the stirring tank, stir at a low speed, and the stirring speed is 300rpm;

[0030] 3. Slowly inject MESAMOLL and ethylene vinyl acetate impregnation material into...

Embodiment 2

[0032] Embodiment 2: high and low temperature resistant solid softener for polar rubber

[0033] The solid softener produced contains the following components (wt.%): carbon nanotubes, nano-kaolin, polyethylene glycol, thermoplastic styrene-butadiene rubber, ester polar softener TP95, and the ratio is: 8:8 :0.5:3.5:80, the specific production steps are as follows:

[0034] 1. First add the softener TP95 and thermoplastic styrene-butadiene rubber into the reaction kettle, stir at a high temperature of 150°C, wait for the thermoplastic styrene-butadiene rubber and softener to fully infiltrate, discharge the material, and place it in a constant temperature tank;

[0035] 2. Add carbon nanotubes, nano-kaolin, and polyethylene glycol into the stirring tank according to the above ratio at room temperature, close the top cover of the stirring tank, stir at a low speed, and the stirring speed is 300rpm;

[0036] 3. Slowly inject the softener TP95 and thermoplastic styrene-butadiene rub...

Embodiment 3

[0038] Embodiment 3: Special environment-friendly solid softener for tires

[0039] The produced solid softener contains the following components (wt.%): carbon nanotubes, white carbon black, nano-kaolin, stearic acid, thermoplastic styrene-butadiene rubber, and environmentally friendly aromatic oil, and the ratio is: 7:5: 5:0.5:2.5:80, the specific production steps are as follows:

[0040] 1. First, add environmental-friendly aromatic oil and thermoplastic styrene-butadiene rubber into the reaction kettle, stir at a high temperature of 100°C, and discharge the material after the thermoplastic styrene-butadiene rubber and aromatic hydrocarbon oil are fully infiltrated, and place them in a constant temperature tank;

[0041] 2. Add carbon nanotubes, white carbon black, nano-kaolin, and stearic acid to the stirring tank at room temperature, close the top cover of the stirring tank, stir at a low speed, and the stirring speed is 300rpm;

[0042] 3. Slowly inject thermoplastic st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com