Solid electrolyte as well as preparation method and application thereof

A technology of solid electrolyte and ceramic electrolyte, which is applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc. It can solve the problems of easy damage, low mechanical strength, and reduced diffusion rate of lithium ions in mechanical properties, so as to achieve uniform dispersion and improve electrical conductivity. The effect of improving the interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

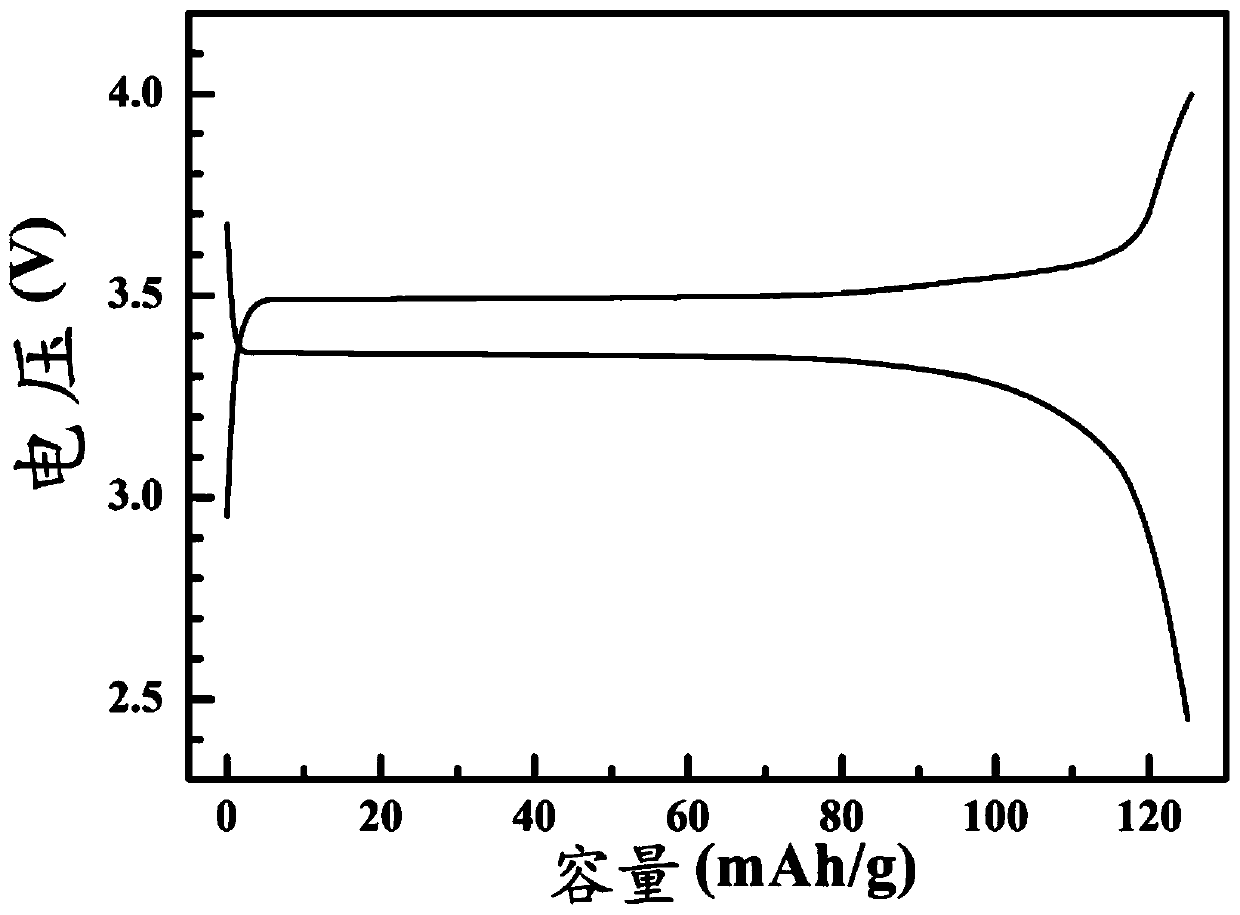

[0042] Dissolve vinylidene fluoride in N-methylpyrrolidone to obtain a solution with a concentration of 16g / L, and stir for 1 hour, then place it in an oven with a temperature of 135°C for 48 hours, then rinse with solvent, wash and dry Obtain modified vinylidene fluoride; the above-mentioned modified vinylidene fluoride, Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Ceramic electrolyte (particle size: 50-100nm) and lithium bistrifluoromethanesulfonylimide are added to the liquid ethoxylated trimethylolpropane triacrylate monomer, and then the initiator azobisisobutyronitrile ( The addition amount is 1wt% of ethoxylated trimethylolpropane triacrylate monomer), wherein, the addition amount of modified vinylidene fluoride, ceramic electrolyte and bistrifluoromethanesulfonylimide lithium is respectively ethoxylated Add 25%, 10% and 25% of the weight of trimethylolpropane triacrylate monomer, and pour it into a polytetrafluoroethylene mold after fully stirring; finally, place the above mold ...

Embodiment 2

[0053] The preparation of the solid electrolyte is similar to that in Example 1, except that the acrylate monomer used is methyl methacrylate. After testing, the solid electrolyte prepared in this embodiment has poor mechanical properties, low thermal stability, and low lithium ion conductivity.

[0054] The solid-state electrolyte assembled battery prepared by this embodiment, wherein the positive electrode is LiFePO 4 , the negative electrode is lithium metal, tested at 0.05C, 60℃ current, LiFePO 4 The capacity of the positive electrode material is 104mAh / g.

Embodiment 3

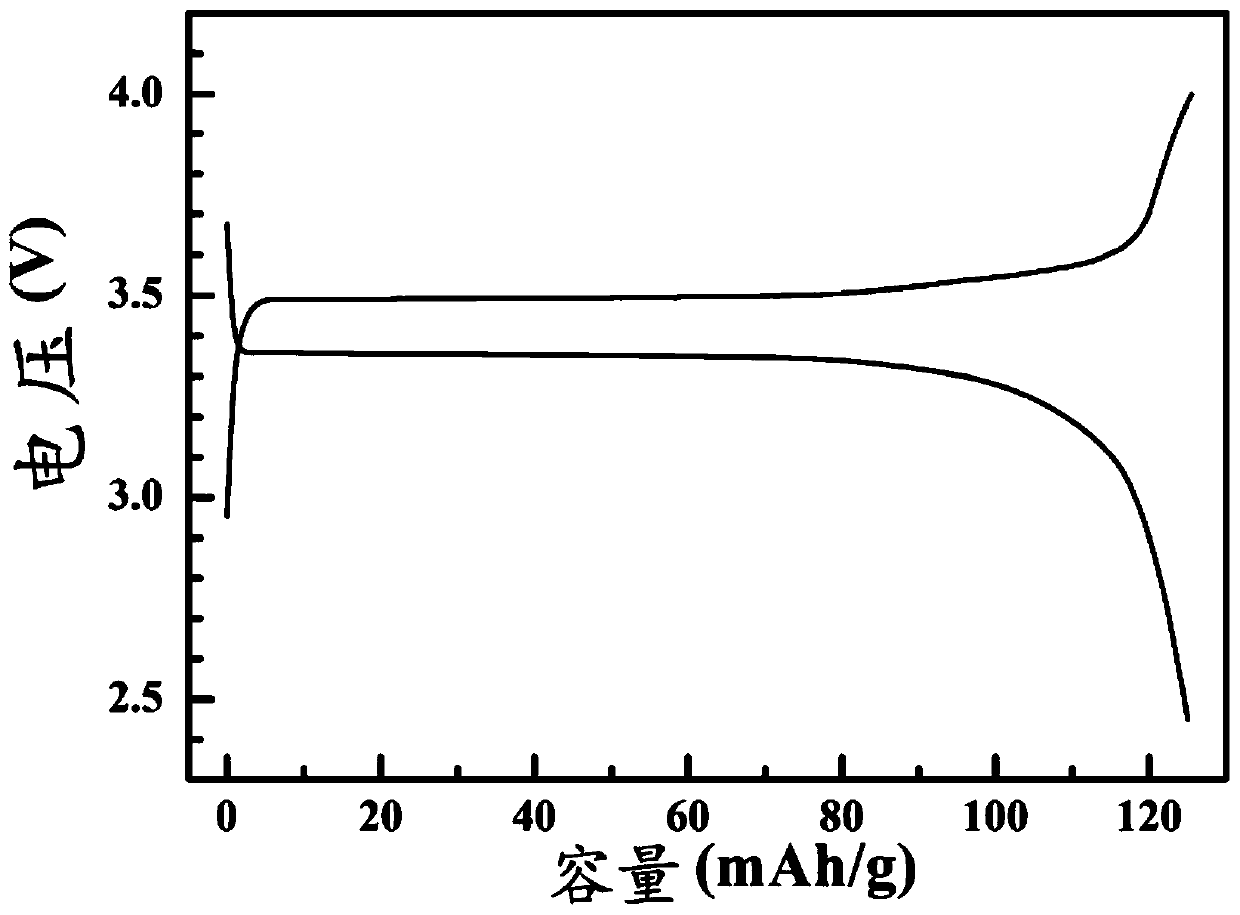

[0056] Dissolve polyvinylidene fluoride-hexafluoropropylene in N-methylpyrrolidone to obtain a solution with a concentration of 16g / L, and stir it for 1 hour, then place it in an oven with a temperature of 135°C for 48 hours, and then vacuum hair, washing and drying to obtain modified polyvinylidene fluoride-hexafluoropropylene; the above modified polyvinylidene fluoride-hexafluoropropylene, Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Add ceramic electrolyte (particle size 50-100nm), lithium hexafluorophosphate into liquid tetraethylene glycol dimethacrylate monomer, and then add initiator azobisisobutyronitrile (addition amount is tetraethylene glycol dimethacrylate 1wt% of ester monomer), wherein, the addition of modified polyvinylidene fluoride-hexafluoropropylene, ceramic electrolyte and lithium hexafluorophosphate is respectively 10%, 5% and 10% of the weight of tetraethylene glycol dimethacrylate monomer %, after being fully stirred, poured into a polytetrafluoroethylene mold; fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com