Annealing and pickling system for stainless steel strip

A stainless steel strip and pickling technology, which is applied in the field of stainless steel, can solve the problems of acid fluctuations and large acid discharge in the pickling process, and achieve the effects of small roughness, improved machinability, and repair of crystal phase structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below.

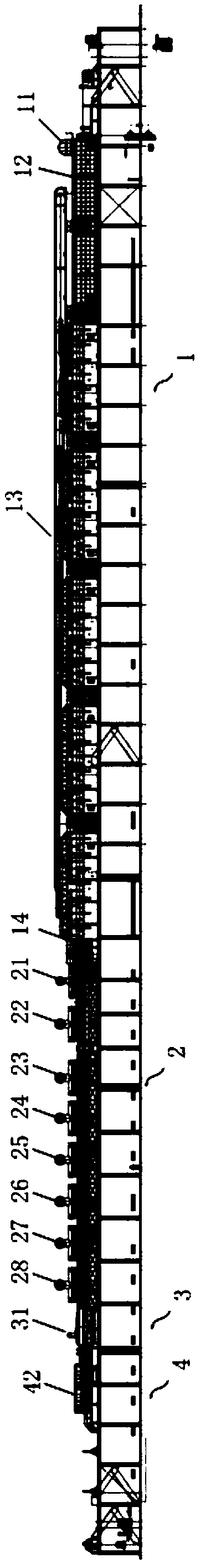

[0068] An annealing and pickling system for stainless steel strips provided by the invention includes an annealing section and a pickling section.

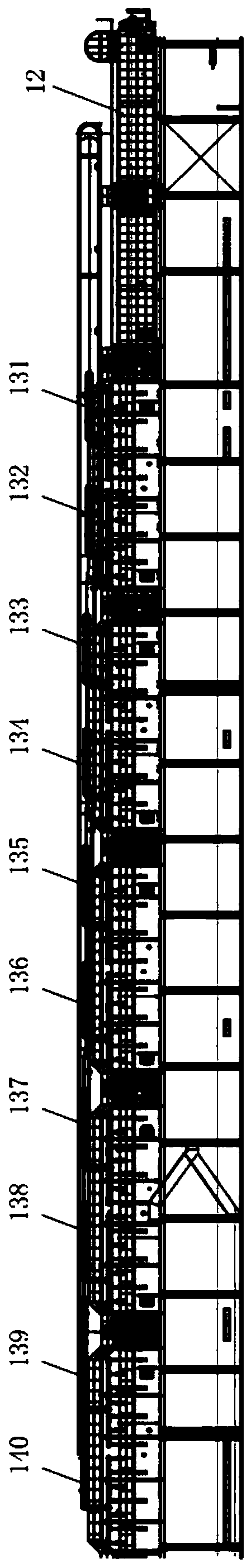

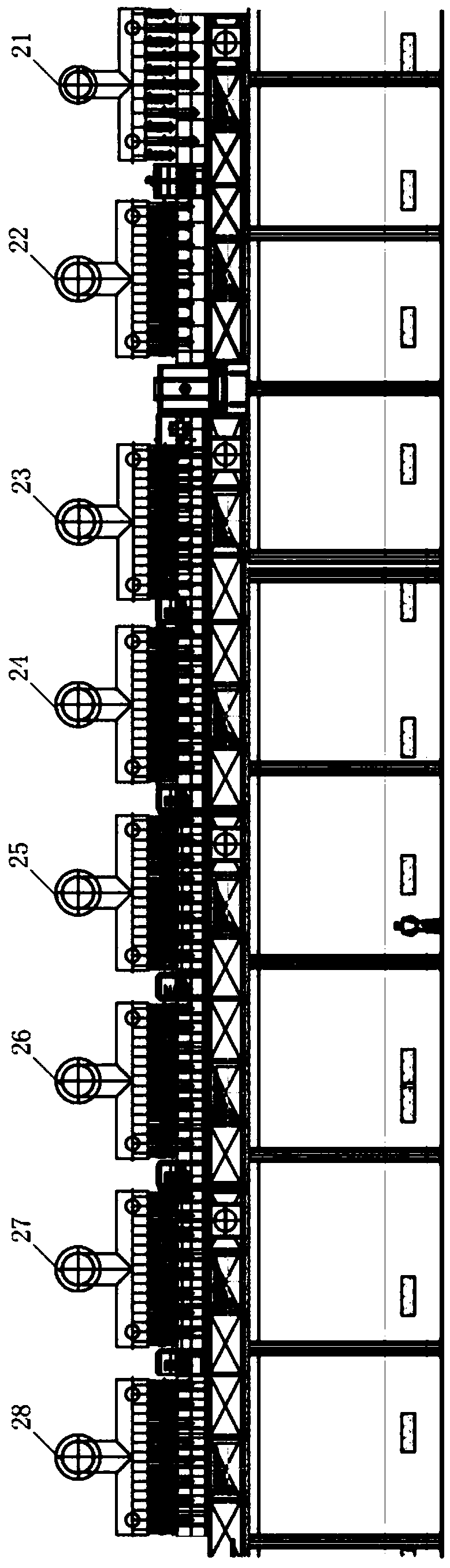

[0069] Such as figure 1 As shown, the annealing section includes a heating mechanism 1, an air cooling mechanism 2, a water cooling mechanism 3 and a drying mechanism 4, wherein the heating mechanism 1 includes an inlet sealing section 11, a preheating zone 12, a heating zone 13 and an outlet sealing section 14 , the inlet sealing section 11 and the outlet sealing section 14 encapsulate the preheating zone 12 and the heating zone 13 as a closed mechanism, and the heating zone 13 is provided with heating nozzles, and the heating nozzles eject flames to heat the stainless steel strip , and generate flue gas to make the stainless steel strip from T 1 Heating to 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com