A rotary reciprocating motion device based on gear meshing and direction change

A technology of reciprocating motion and rotary motion, applied in the transmission device, friction transmission device, winch device, etc., can solve the problems of overheating failure of components such as solenoid valves, high operating speed and easy damage, and relying on a stable air pressure source, etc. The reciprocating motion is not easy, the production cost is low, and the noise is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

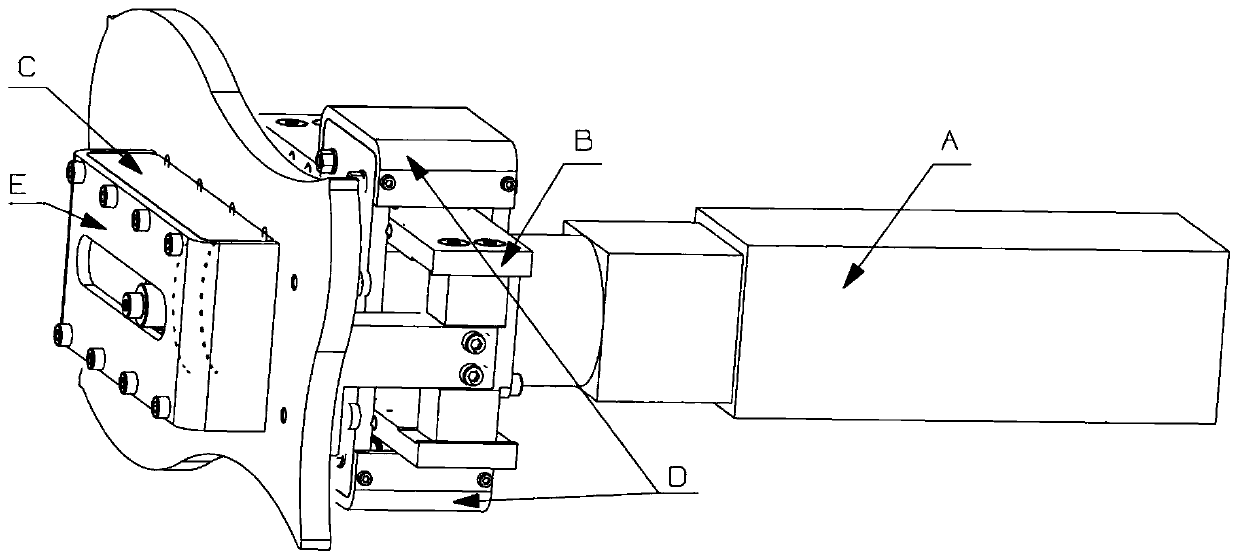

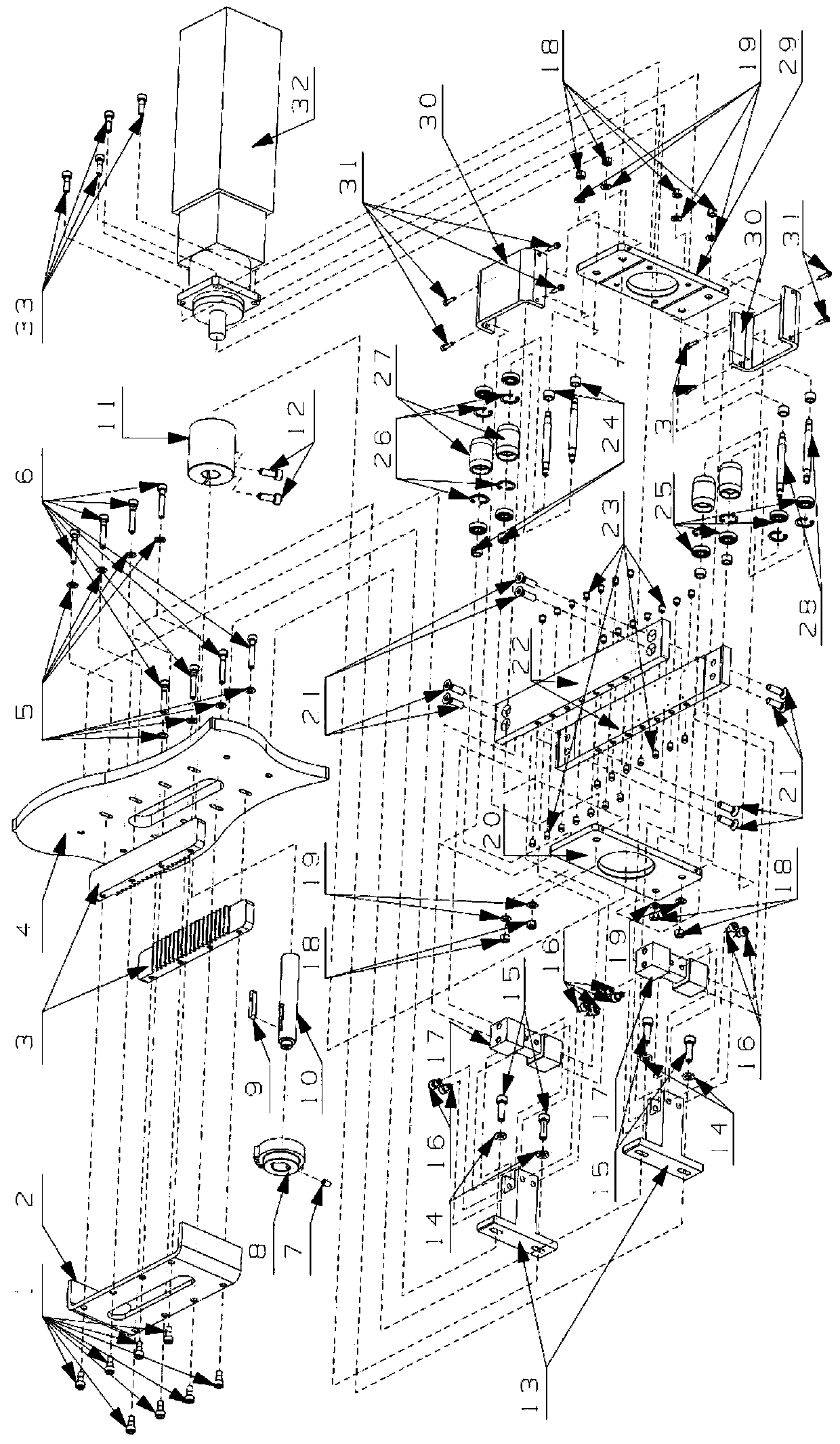

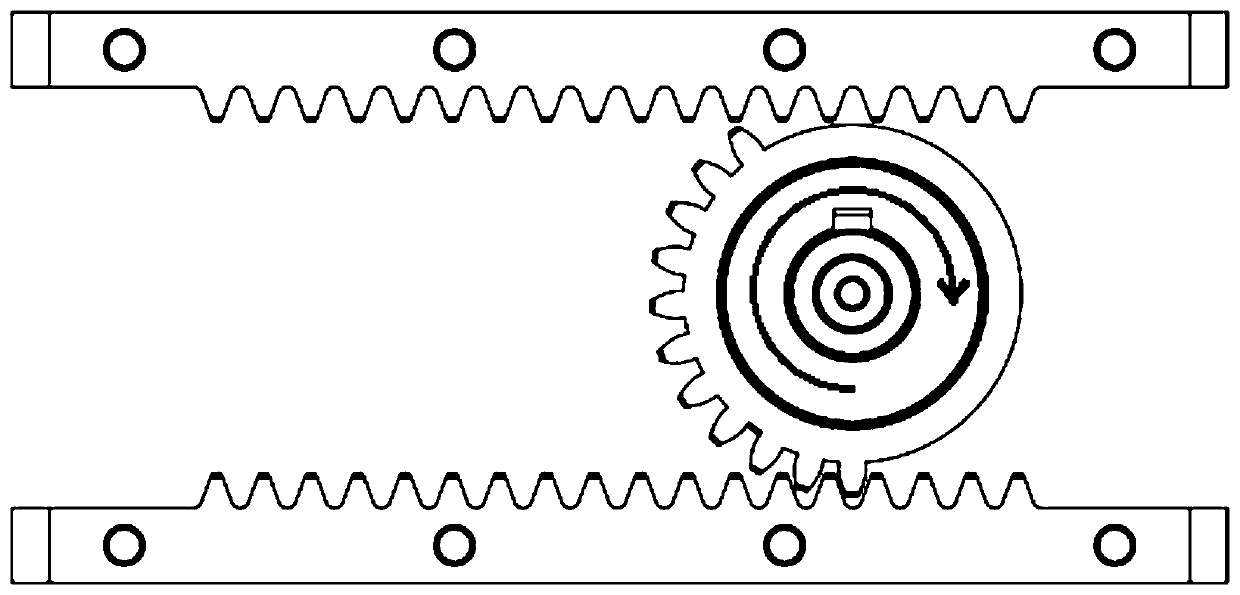

[0025] Embodiment 1: as Figure 1-5 As shown, a rotary reciprocating motion device based on gear meshing and direction change includes a power source A, a motion conversion system C, and a base 4; the power source A provides power; the motion conversion system C includes a rotary motion structure, a reciprocating Motion structure; the rotary motion structure and the power source A are connected as a whole in the axial direction of the power source A, the upper and lower transmission racks 3 in the reciprocating motion structure are connected and fixed with the mounting surface of the base 4, and the conversion gear 8 in the rotary motion structure is used as The intersection of the two structures of the rotating structure and the reciprocating structure drives the reciprocating structure and the rolling structure to reciprocate.

[0026] Further, the power source A can be set as a programmable servo motor 32 with a matching reducer; the size of the two is determined according ...

Embodiment 2

[0038] Embodiment 2: as Figure 5-7 As shown, it is basically the same as Embodiment 1, and the difference is that the specific structure in the displacement positioning system B is replaced as follows:

[0039]The reciprocating plate adopts a reciprocating plate II35; the rolling support plate group adopts an upper plate 40, a lower plate 41, and two connecting plates 37; Head screw), positioning rod Ⅱ42, deep groove ball bearing Ⅱ43, roller Ⅱ44 (both ends of the roller Ⅱ44 are equipped with bearing installation round grooves; the working surface needs to be treated with hard chrome plating, and the thickness of the chrome plating layer is 0.05-0.07mm, which can reach a relatively high level. High wear resistance to avoid excessive wear and tear failure; after plating, the circular runout tolerance of the working face should reach 0.03mm or less, and the dimensional tolerance level should be guaranteed to reach h7 level, so as to ensure that it can be achieved under the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com