Nuclear fuel failure detection device and method

A technology for damage detection and nuclear fuel, which is applied in nuclear engineering, nuclear power generation, nuclear reactor monitoring, etc., can solve the problems of inaccurate detection results and inability to accurately judge leakage, and achieve high precision, accurate and reliable measurement results, and increased The effect of receiving area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

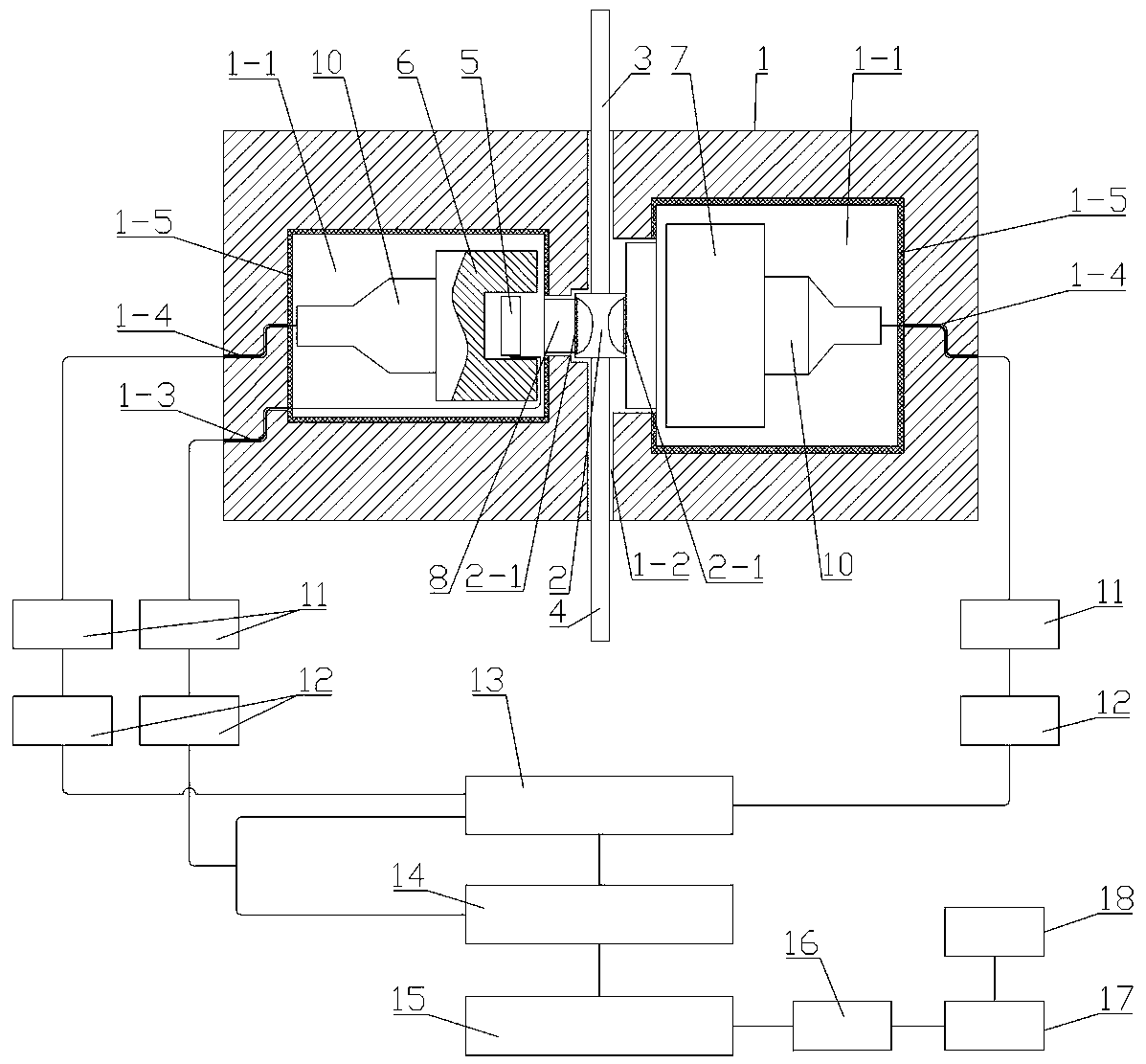

[0045] Such as figure 1 As shown, the nuclear fuel damage detection device includes a lead shielding shell 1, a sampling chamber 2, an air inlet pipe 3, an air outlet pipe 4, a main detector 5, a scintillation detector A6, a scintillation detector B7, a collimator A8, and a collimator B9 , photomultiplier tube 10, preamplifier 11, linear amplifier 12, anticoincidence counting circuit 13, gate circuit 14, pulse amplitude analyzer 15, comprehensive analyzer 16, data processor 17 and display screen 18.

[0046] The lead shielding case 1 is provided with a component installation cavity 1-1, and the outer wall of the lead shielding case 1 is provided with a signal line perforation A1-3 connected to the component installation cavity 1-1 and a signal line perforation connected to the component installation cavity 1-1 B1-4, the inner wall of the component installation cavity 1-1 is provided with a shielding layer 1-5, and the shielding layer 1-5 is used in 133 The Xe detection area (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com