Air-cooled heat dissipation system for battery pack and thermal management method thereof

A technology for cooling systems and battery packs, applied in secondary batteries, battery temperature control, circuits, etc., can solve the problems of difficulty in controlling the local temperature difference of the battery pack, and the inability to meet the heat dissipation requirements of multiple working conditions, so as to solve the abnormal rise in battery temperature. , Conducive to large-scale application promotion, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

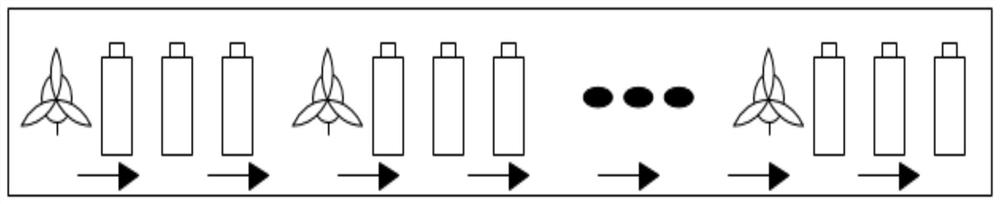

[0035] Such as figure 1 As shown, this embodiment provides an air-cooled heat dissipation structure for a battery pack, including:

[0036] A battery pack composed of M battery cells, a box for accommodating the battery pack, and opposite ends of the box having air inlets and air outlets communicating with the box;

[0037] The fan used for ventilation and heat dissipation, in this embodiment, from the air inlet at one end of the box to the air outlet at the other end of the box every Each battery cell is equipped with a fan, that is, any Fans are installed at the beginning and end of a battery pack composed of two battery cells, and the temperature of the battery section is cooled by air cooling;

[0038] Temperature sensors for monitoring the temperature of various parts of the battery pack;

[0039] A current sensor for detecting the discharge current of the battery pack;

[0040] central control unit

[0041] Control circuit;

[0042] The battery pack, temperature ...

Embodiment 2

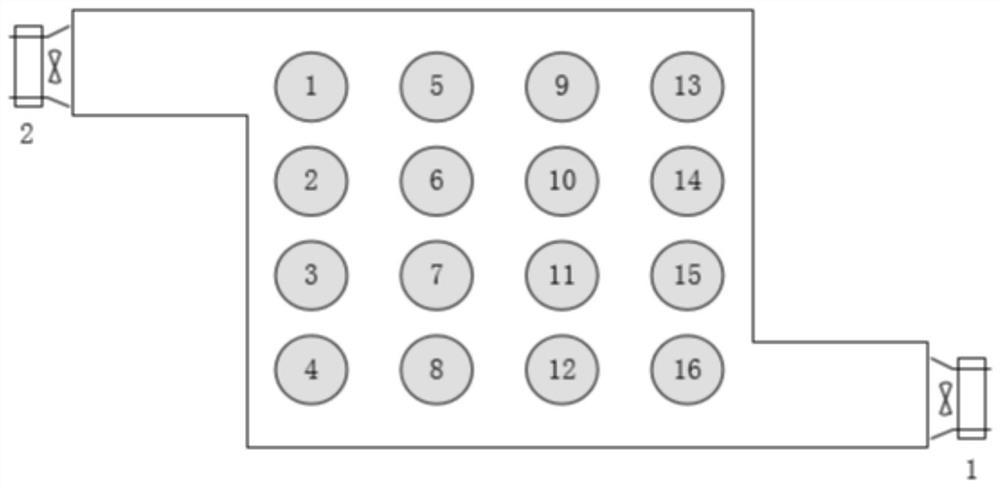

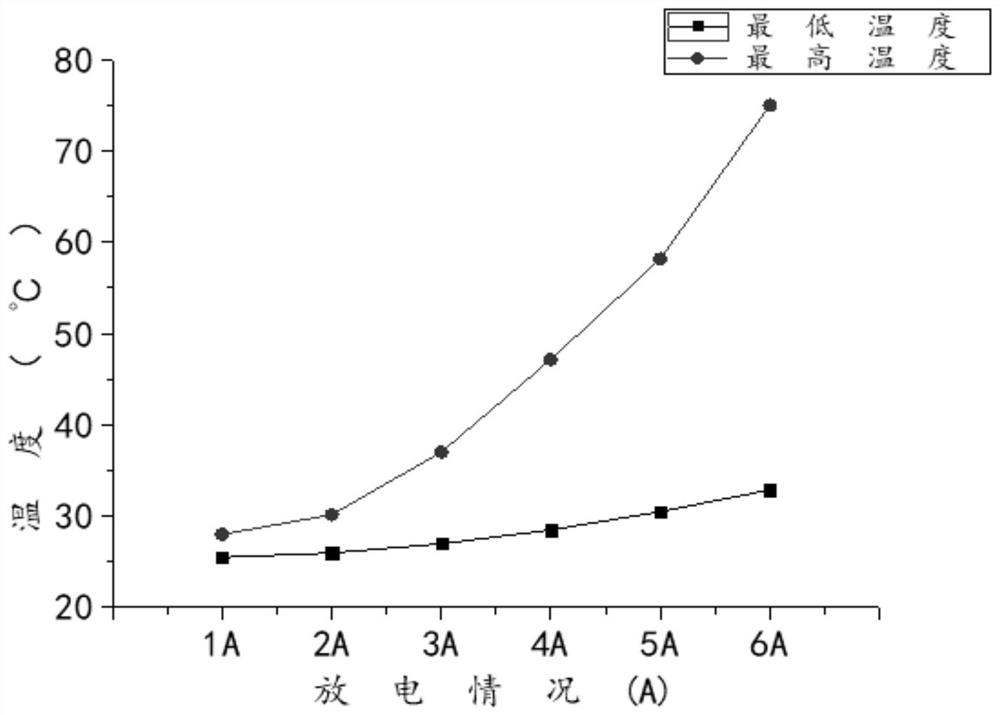

[0044] This embodiment is based on figure 2 The parallel ventilation and heat dissipation structure of the battery pack shown is used for simulation analysis of the battery pack. The battery pack studied in this example uses a domestic 18650 lithium iron phosphate battery. The entire battery pack is composed of 16 monomers to form a 48V battery pack. Lithium-ion batteries work at 25°C-45°C, and the maximum temperature difference between batteries is 5°C. The battery interval in the battery pack is 5mm. In order to prevent backflow, the length of the air inlet and air outlet pipes is extended. A blower is respectively placed at the two pipe openings. When No. 1 blower starts, No. 2 blower turns off, the right pipe is the air inlet, and the left pipe is the air outlet; when No. 2 blower starts, No. 1 blower is turned off, the left pipe is the air inlet, and the right pipe is the air outlet.

[0045] When the No. 1 blower starts and the No. 2 blower turns off, a large amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com