Catalyst for synthesizing p-tolualdehyde

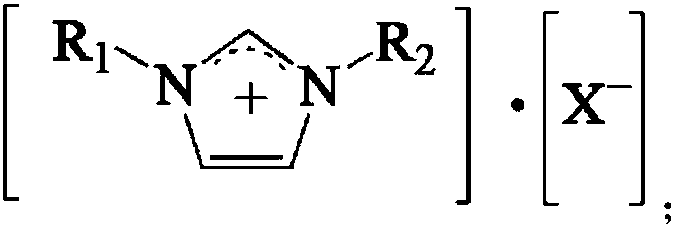

A technology of p-toluene and catalyst, applied in physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, organic chemistry, etc., can solve the low yield of toluene conversion rate p-toluene And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Add 1-butyl-3-methylimidazolium hexafluoroantimonate (0.5mol, 187g) and Sc(CF 3 SO 3 ) 3 (0.5mol, 246g), the air in the kettle is first replaced with N 2 Replaced 3 times, and then replaced 3 times with CO gas; stirred at 500rpm for 1h; added 110g of toluene; replaced the air in the kettle with CO gas 3 times; Product mixture of methylbenzaldehyde.

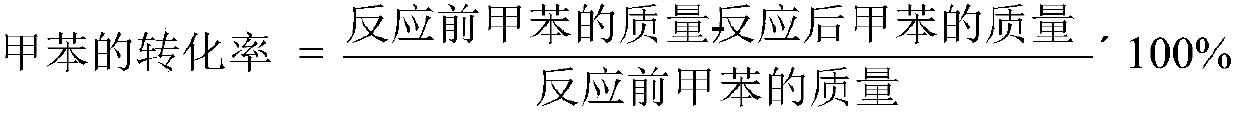

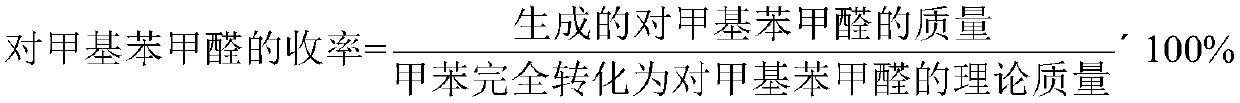

[0048] For ease of comparison and illustration, the catalyst formula is listed in Table 1, and the conversion rate of toluene and the yield of p-tolualdehyde are listed in Table 2.

Embodiment 2

[0050] Add 1-butyl-3-methylimidazolium hexafluorophosphate (0.5mol, 142g) and Sc(CF 3 SO 3 ) 3 (0.5mol, 246g), the air in the kettle is first replaced with N 2 Replaced 3 times, then replaced 3 times with CO gas; stirred at 500rpm for 1h; added 110g of toluene; replaced the air in the kettle with CO gas; Product mixture of benzaldehyde.

[0051] For ease of comparison and illustration, the catalyst formula is listed in Table 1, and the conversion rate of toluene and the yield of p-tolualdehyde are listed in Table 2.

Embodiment 3

[0053] Add 1-butyl-3-methylimidazolium hexafluoroantimonate (0.5mol, 187g) and Ce(CF 3 SO 3 ) 3 (0.5mol, 299g); the air in the kettle is firstly used with N 2 Replaced 3 times, and then replaced 3 times with CO gas; stirred at 500rpm for 1h; added 110g of toluene; replaced the air in the kettle with CO gas 3 times; Product mixture of methylbenzaldehyde.

[0054] For ease of comparison and illustration, the catalyst formula is listed in Table 1, and the conversion rate of toluene and the yield of p-tolualdehyde are listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com