A Roller Reset Method for Roll Extrusion Forming Rollers with Variable Wall Thickness

A reset method and wall thickness-changing technology, which is applied to household appliances, hollow objects, and other household appliances, can solve problems such as the inability to quickly eliminate roller misalignment online, improve production efficiency and workpiece forming accuracy, and ensure continuity. The effect of reducing the difficulty of assembly and reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

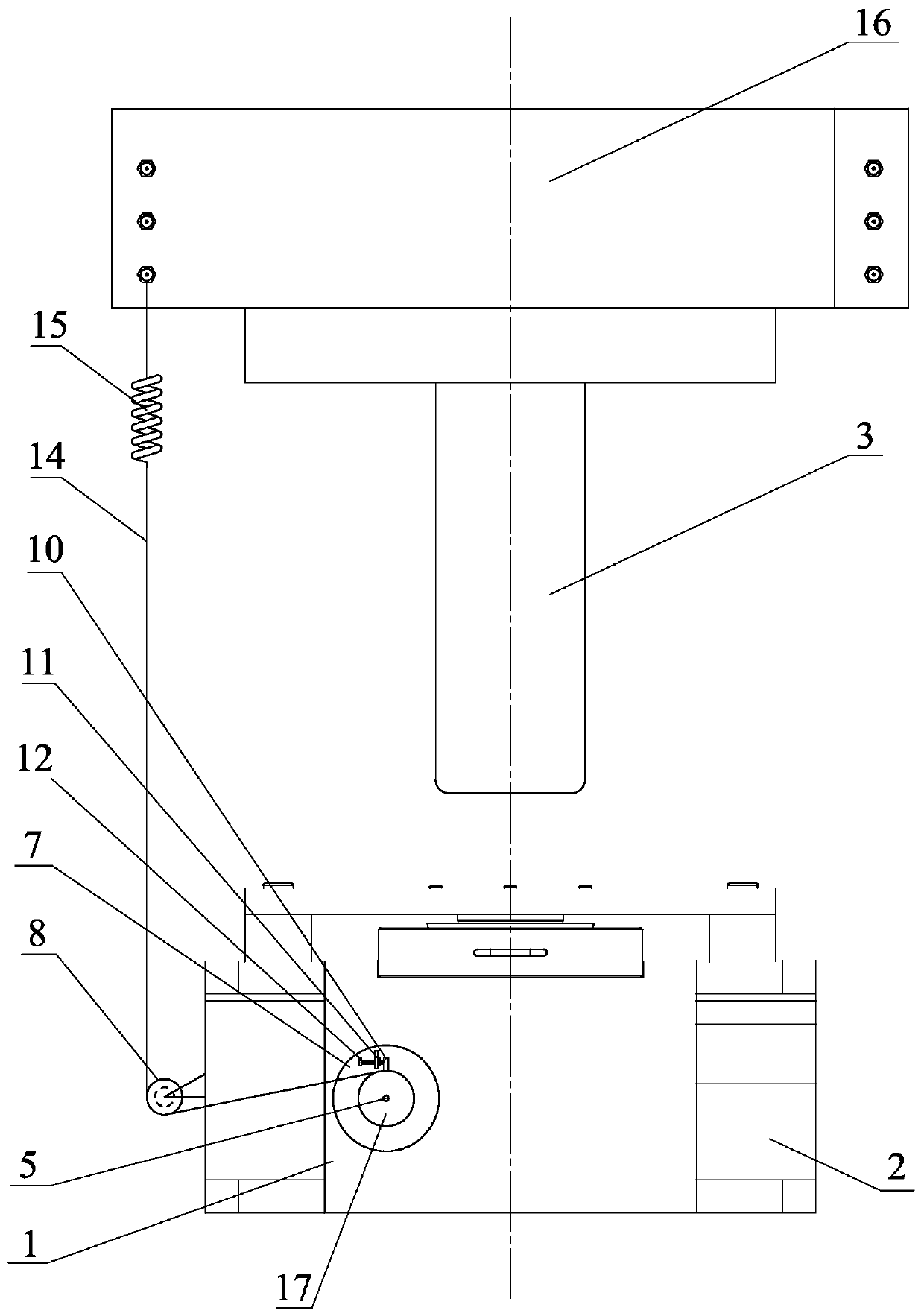

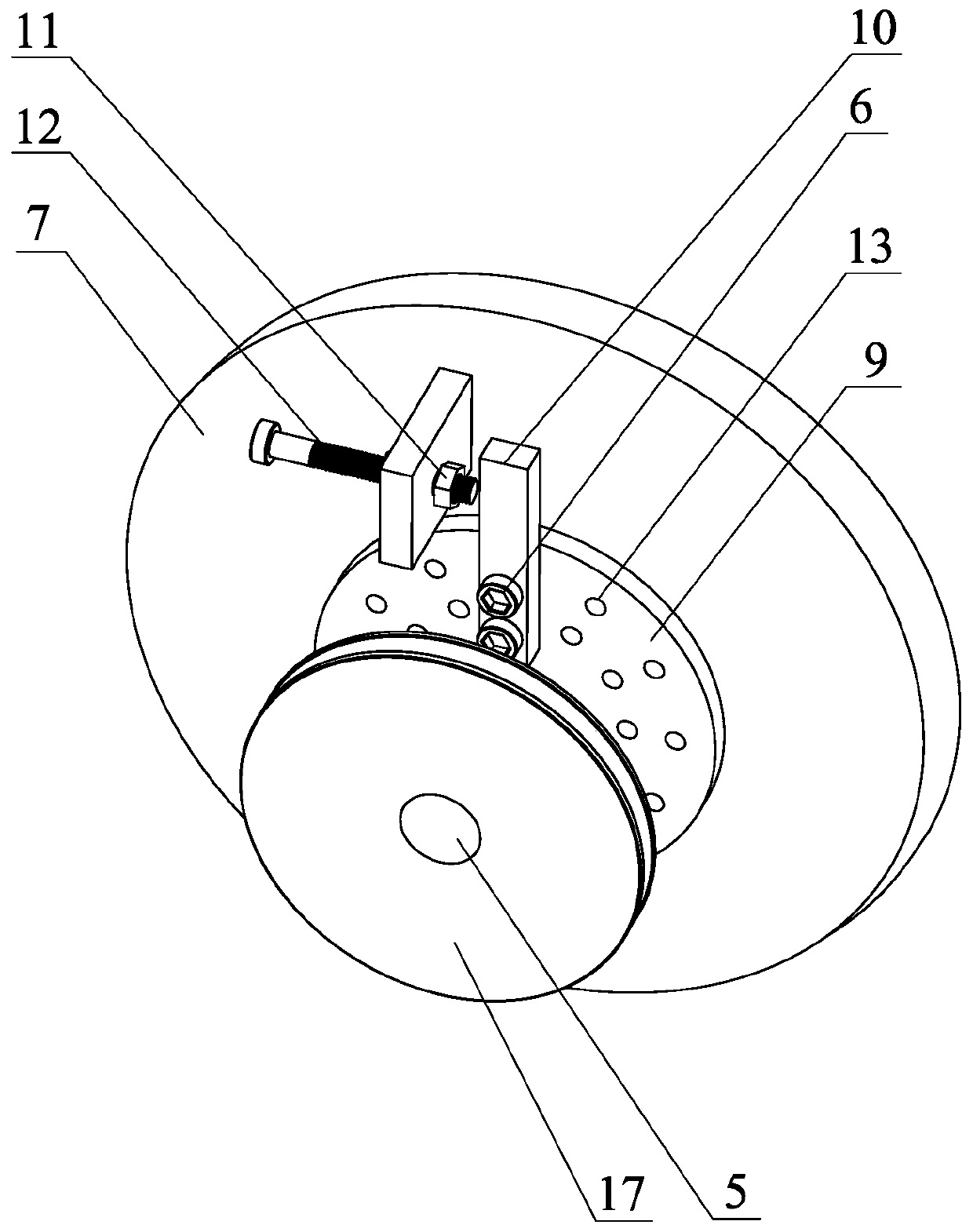

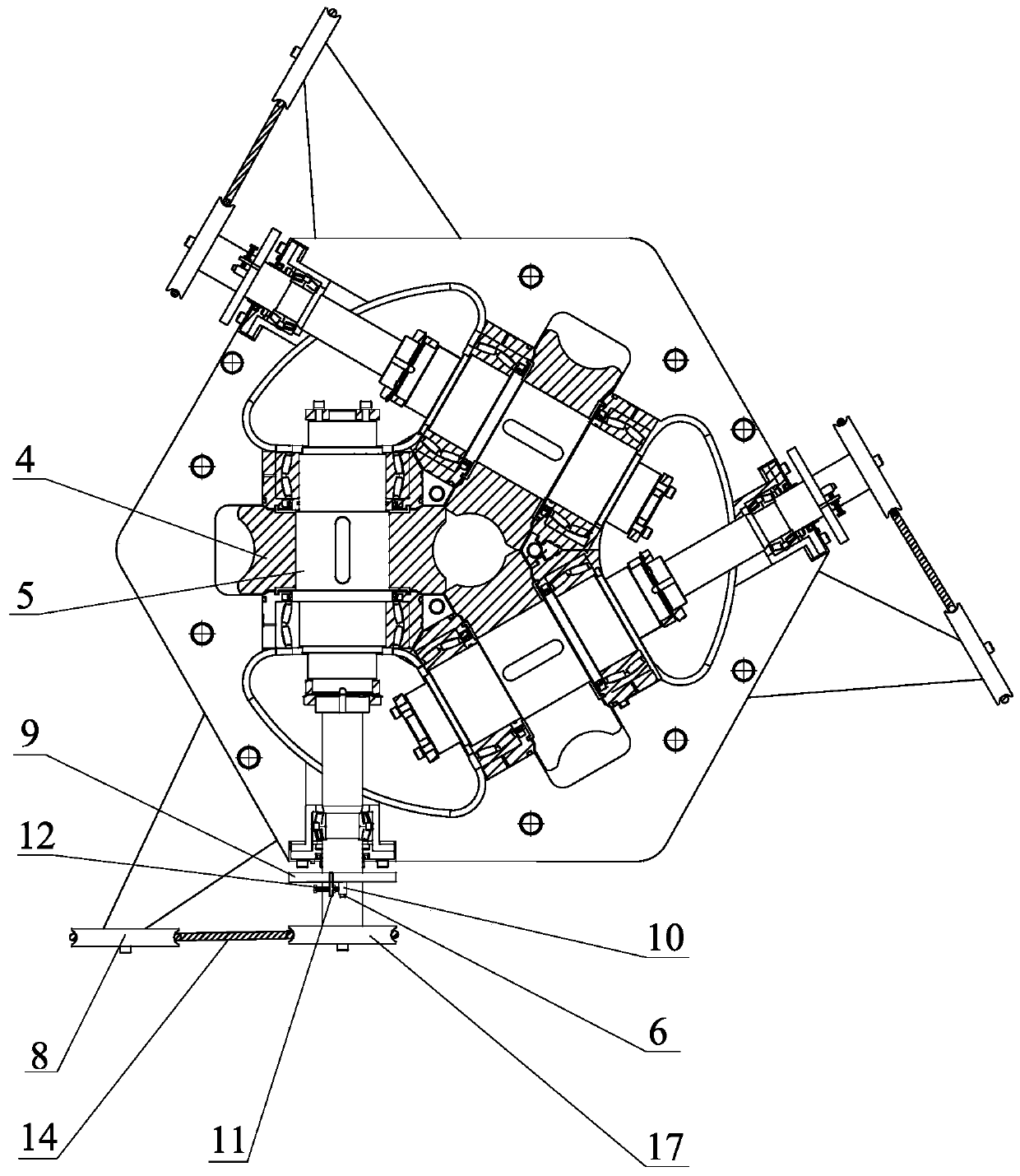

[0017] A method for resetting rollers in roll extrusion forming of variable-wall-thickness cylinder parts disclosed by the present invention, see Figure 1-4 , the resetting method relates to a roll extrusion forming device for variable wall thickness cylindrical parts, the forming device includes a frame 1, an upper beam 16 of a hydraulic press, and two upper and lower layers of rolling mechanisms, and each layer of rolling mechanisms includes three rollers 4 , each roller shaft 5 corresponds to an independent reset device;

[0018] The resetting device includes a seat body 7, a wire rope 14, a first pulley 8, a second pulley 17, an extension spring 15, a limit plate 9, a baffle plate 10, a nut 11, a limit bolt 12 and a connecting bolt 6, and the seat body 7 is fixed. On the frame 1, the roller shaft 5 passes through the seat body 7 and sleeves the limit plate 9 and the second pulley 17, the position-changing baffle plate 10 is installed on the limit plate 9, and the seat bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com