Preparing method for self-supporting half-infiltration self-adhesion non-buckling pre-sized fabric

A pre-shaped, self-supporting technology, applied in the field of low-cost preparation of high-performance composite materials, can solve the problems that are not conducive to the flow and infiltration of liquid resin, affect the mechanical properties of composite materials, and low in-plane mechanical properties, so as to improve the laying process , Improving the manufacturability of operation and the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

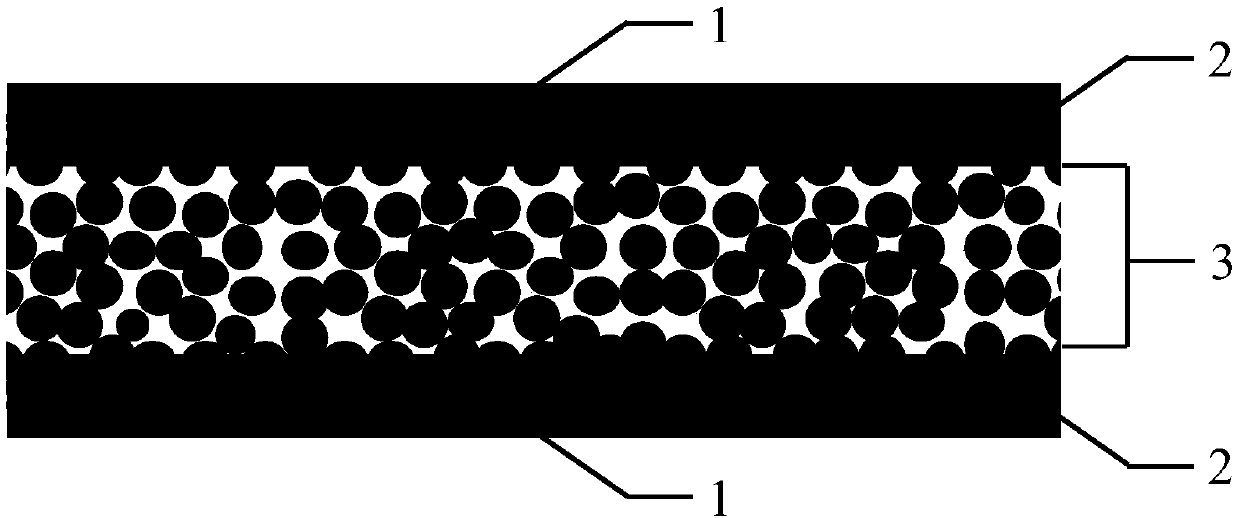

Image

Examples

specific Embodiment 1

[0025] High tenacity epoxy resin is used as the matrix resin of the pre-set fabric, domestic T800 12K carbon fiber is used as the reinforcing fiber of the pre-set fabric, nylon non-woven fabric is used as the connection and toughening material, and the surface density of the pre-set fabric is 201g / m 2 , the width is 300mm, and the fiber surface density is 145g / m 2 , The surface density of nylon non-woven fabric is 10g / m 2 , The surface density of the resin film is 18g / m 2 . The preparation process of self-supporting semi-impregnated self-adhesive non-buckling pre-set fabric is discussed.

[0026] (a) Preheat the high-toughness epoxy resin and put it into the glue film machine, and prepare the areal density of 18g / m under the condition of the resin viscosity of 120Pa·s 2 (accounting for 9% of the mass content of the preformed fabric) continuous resin film;

[0027](b) Calculated on the basis of 300mm width and fiber bundle yarn density of 0.45g / m, the fiber surface density ...

specific Embodiment 2

[0031] Using high-toughness bismaleimide resin as the matrix resin of the pre-set fabric, domestic T700 12K carbon fiber as the reinforcing fiber of the pre-set fabric, and polyaryletherketone non-woven fabric as the connection and toughening material, the pre-set fabric Area density 199g / m 2 , the width is 1000mm, and the fiber surface density is 133g / m 2 , Polyaryletherketone non-woven fabric surface density is 15g / m 2 , The surface density of the resin film is 18g / m 2 . The preparation process of self-supporting semi-impregnated self-adhesive non-buckling pre-set fabric is discussed.

[0032] (a) Preheat the high-toughness bismaleimide resin and put it into the film machine, and prepare the areal density of 18g / m under the condition of the resin viscosity of 100Pa·s 2 (accounting for 9% of the mass content of the preformed fabric) continuous resin film;

[0033] (b) Calculated on the basis of a width of 1000mm and a fiber bundle yarn density of 0.80g / m, the fiber surfa...

specific Embodiment 3

[0037] Cyanate resin is used as the matrix resin of the pre-set fabric, domestic M40J 12K carbon fiber is used as the reinforcing fiber of the pre-set fabric, polyimide non-woven fabric is used as the connection and toughening material, and the surface density of the pre-set fabric is 256g / m 2 , the width is 500mm, and the fiber surface density is 190g / m 2 , Polyimide non-woven fabric surface density is 10g / m 2 , The surface density of the resin film is 23g / m 2 . The preparation process of self-supporting semi-impregnated self-adhesive non-buckling pre-set fabric is discussed.

[0038] (a) Preheat the cyanate resin and put it into the film machine, and prepare the surface density of 23g / m under the condition of the resin viscosity of 140Pa·s 2 (accounting for 9% of the mass content of the preformed fabric) continuous resin film;

[0039] (b) Calculated on the basis of 500mm width and fiber bundle yarn density of 0.45g / m, the fiber surface density is 190g / m 2 , 211 shaft f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com