Self-heat-absorption core-shell toughening material, thermal-breaking structure adhesive film containing self-heat-absorption core-shell toughening material and preparation method and application of thermal-breaking structure adhesive film

A toughening and core-shell technology, applied in the field of thermally broken structural adhesive film and its preparation, can solve the problems that cannot meet the requirements of porosity and bonding strength, and achieve high toughness, high Tg, and high bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

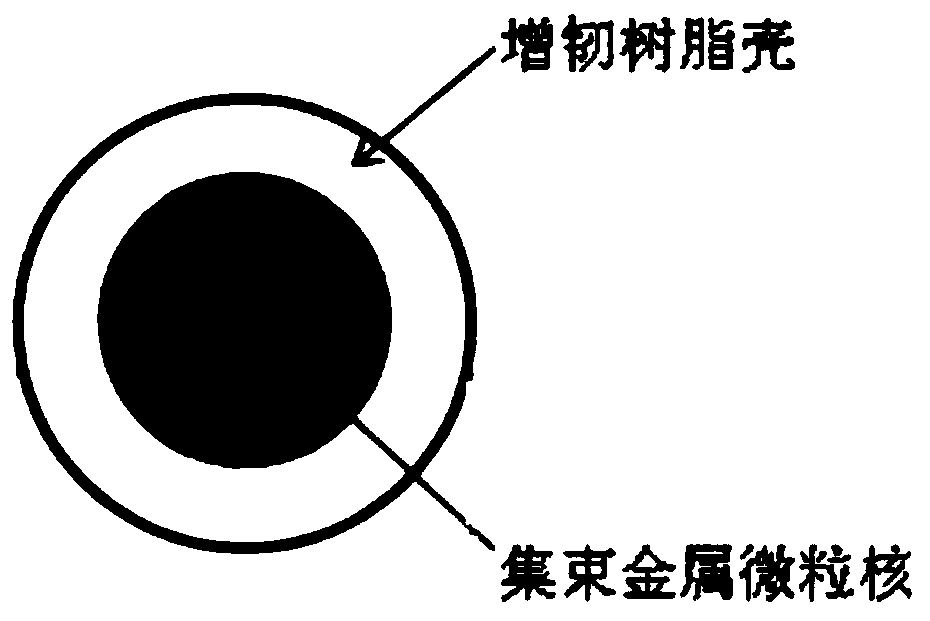

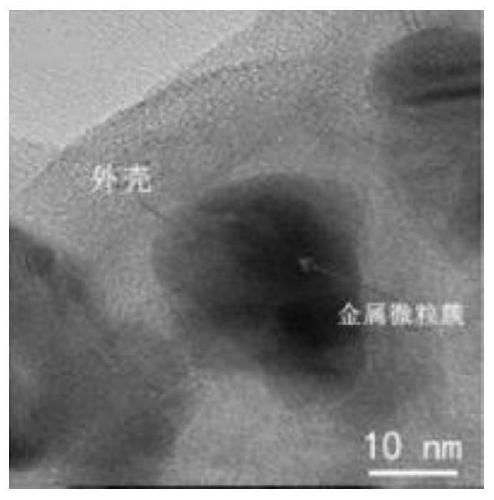

[0035] This example provides a self-absorbing core-shell toughening material and its preparation method:

[0036] Weigh 20 parts of aluminum particles with an average particle size of 15 μm and 80 parts of polyarylethersulfone resin containing active end groups, the structural formula of which is:

[0037]

[0038] The active end group is a hydroxyl group, where n=33;

[0039] Weigh 0.2 parts of interface modifier-3-glycidyl etheroxypropyl trimethoxysilane, 0.5 parts of catalyst-triphenylphosphine, 2 parts of emulsifier-sodium dodecylbenzenesulfonate and 1000 parts of pH 6.0-7.0 deionized water; mix dichloroethane and dimethylformamide at a volume ratio of 1:1, and measure 300 parts of the resulting mixed solvent.

[0040] Mix the metal particles, the interface modifier and 150 parts of mixed solvent into the reaction vessel, stir at room temperature for 1 hour at 2000 r / min under the condition of nitrogen, and leave the reaction system to stand and dry for 5 hours to obta...

Embodiment 2

[0043] This example provides a thermally broken structural adhesive film containing a self-absorbing core-shell toughening material and its preparation method:

[0044] Weigh 25 parts of the self-absorbing heat-absorbing core-shell toughening material prepared in Example 1, 60 parts of cyanate resin-4,4'-dicyanate diphenylmethane, 15 parts of epoxy resin-bisphenol A type Epoxy resin, 2.5 parts of reactive diluent-alicyclic glycidyl ether, 2 parts of filler-fumed silica H-18 and 0.3 parts of accelerator-1,3-diphenylurea.

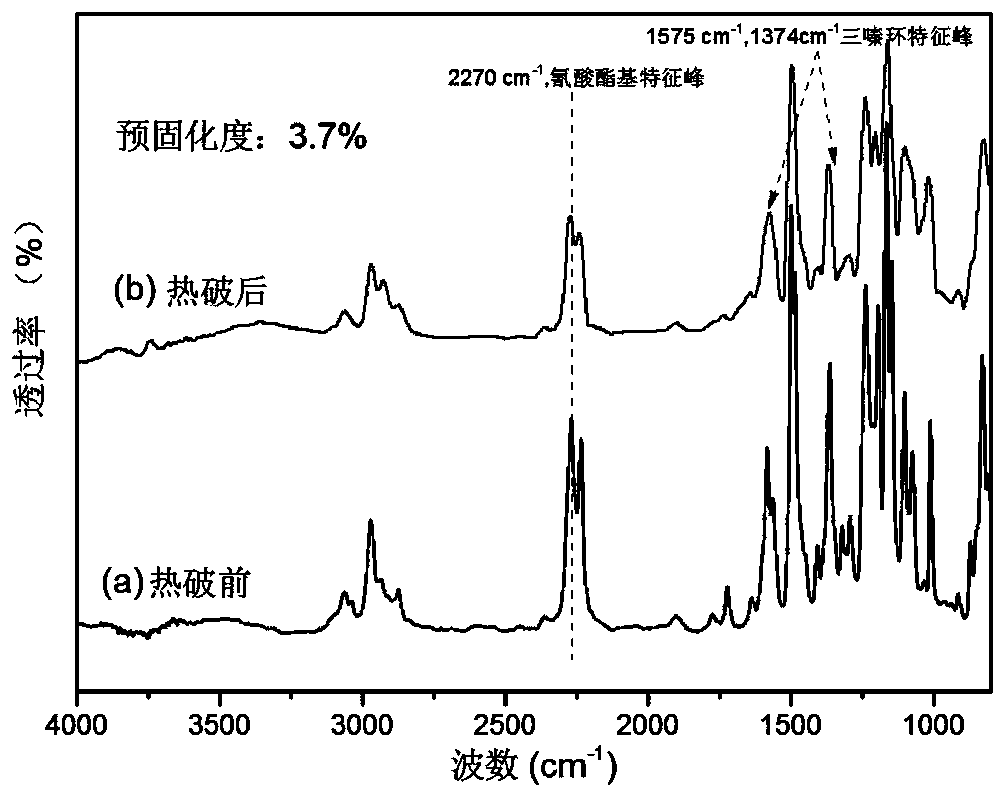

[0045] Mix and heat cyanate resin and epoxy resin to 120°C to dissolve, stir at 1300r / min, maintain the temperature of the resulting mixed system at 150°C, add self-absorbing core-shell toughening material and reactive diluent, stir at 1300r / min for 3.5 h. After the mixed system is homogeneous, immediately transfer to a closed kneader to add fillers and accelerators, and mix for 30 minutes to obtain a light gray viscous compound; maintain the temperature of t...

Embodiment 3

[0054] This example provides a self-absorbing core-shell toughening material and its preparation method:

[0055] Weigh 10 parts of iron particles with an average particle size of 30 μm and 90 parts of polyarylethersulfone resin containing active end groups, the structural formula of which is:

[0056]

[0057] The active end group is a hydroxyl group, where n=33;

[0058] Weigh 0.2 parts of interface modifier-3-methacryloxypropyltrimethyloxysilane, 0.5 parts of catalyst-sodium borohydride, 2 parts of emulsifier-sodium stearate and 1000 parts of pH 6.0~ 7.0 deionized water, dichloroethane and dimethylformamide were mixed at a volume ratio of 1:1, and 300 parts of the resulting mixed solvent were measured.

[0059] Mix the metal particles, the interface modifier and 150 parts of mixed solvent into the reaction vessel, stir at room temperature at 2000r / min for 1.5h under the condition of nitrogen gas, and let the reaction system stand still and dry for 5h to obtain a light g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com