Activated sludge biomembrane composite sewage treatment device and treatment method

A sewage treatment device, activated sludge technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., to achieve the effect of improving the ability to resist shock loads and the ability to degrade pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

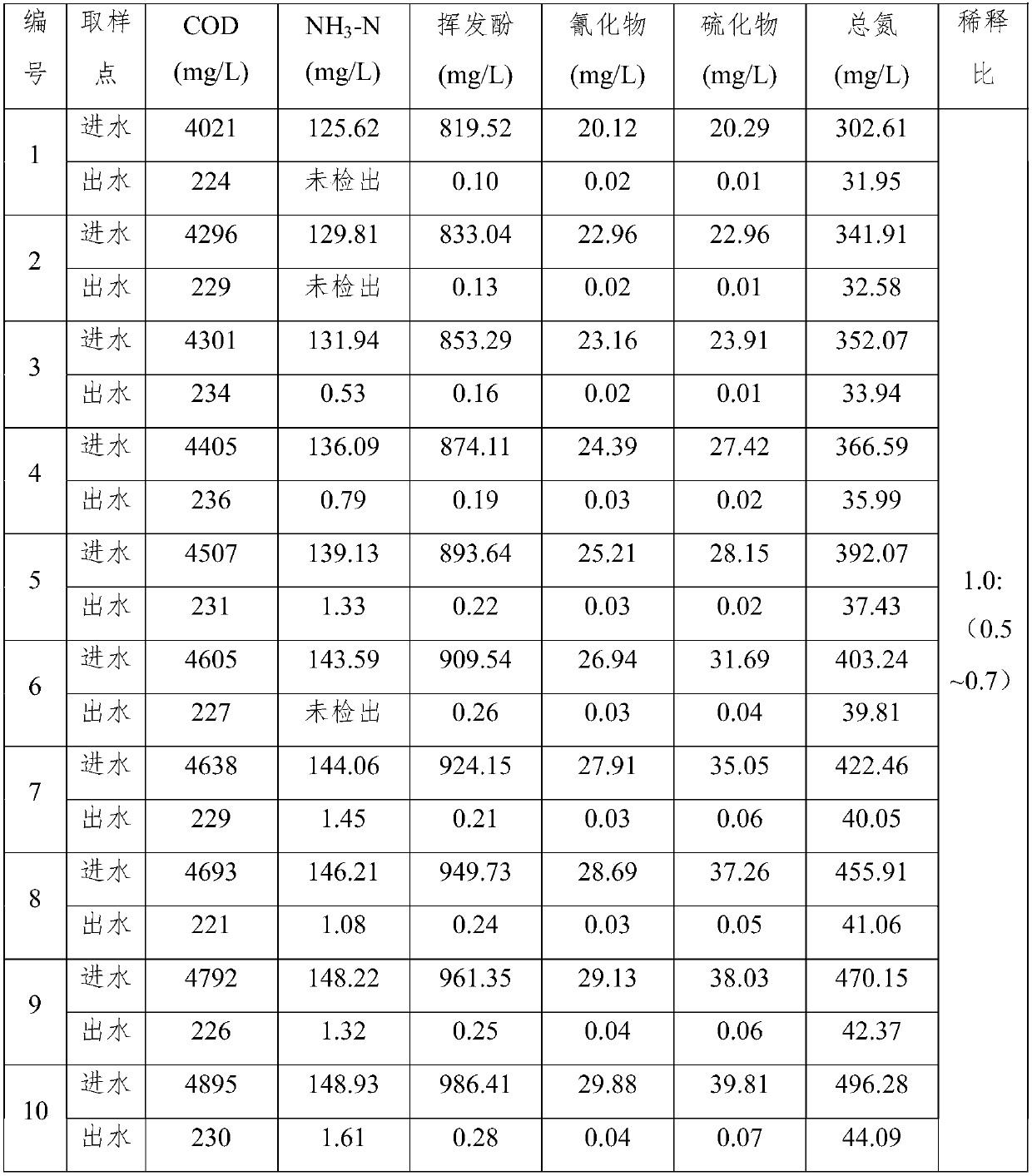

Embodiment 1

[0038] Fix the polyethylene / formylated vinylon composite wire on a plastic ring with a diameter of 150mm to form a faceplate, and fix the faceplate on the central rope through a sleeve with a length of 100mm at intervals to make a biological carrier component, and reserve 350mm at both ends of the biological carrier component center rope.

[0039] Fix the submersible mixer on the side wall at the diagonal bottom of the sump. The height of the designed biological carrier support is 1.8m, the distance between the suspension beams on the biological carrier support is 0.2m, and the length and width of the biological carrier support are determined according to the length and width of the sewage pool. The biological carrier bracket is fixed in the sewage pool, the bottom of the biological carrier bracket is 0.8m away from the bottom of the sewage pool, and the top of the biological carrier bracket is 1.2mm away from the top of the sewage pool.

[0040] Fix the biocarrier assembly o...

Embodiment 2

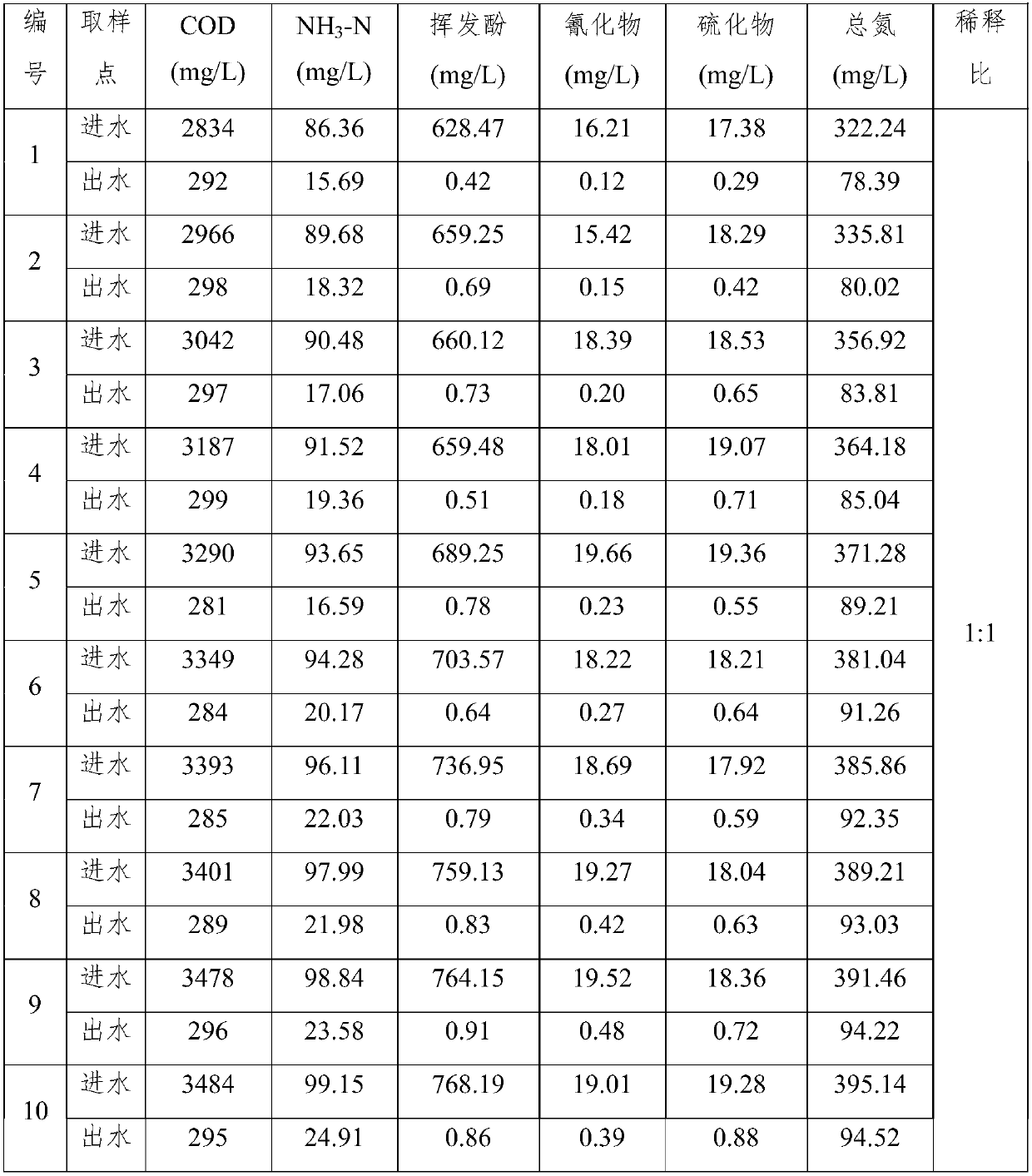

[0054] Fix the polyethylene / formylated vinylon composite wire on a plastic ring with a diameter of 130mm to form a faceplate, and fix the faceplate on the central rope through a sleeve with a length of 60mm at intervals to make a biological carrier component, and reserve 350mm at both ends of the biological carrier component center rope.

[0055] Fix the submersible mixer on the side wall at the diagonal bottom of the sump. The height of the designed biological carrier support is 1.8m, the distance between the suspension beams on the biological carrier support is 0.15m, and the length and width of the biological carrier support are determined according to the length and width of the sewage pool. Fix the biological carrier bracket in the sewage pool, the bottom of the biological carrier bracket is 0.6m away from the bottom of the sewage pool, and the top of the biological carrier bracket is 1.0mm away from the top of the sewage pool.

[0056] Fix the biocarrier assembly on the...

Embodiment 3

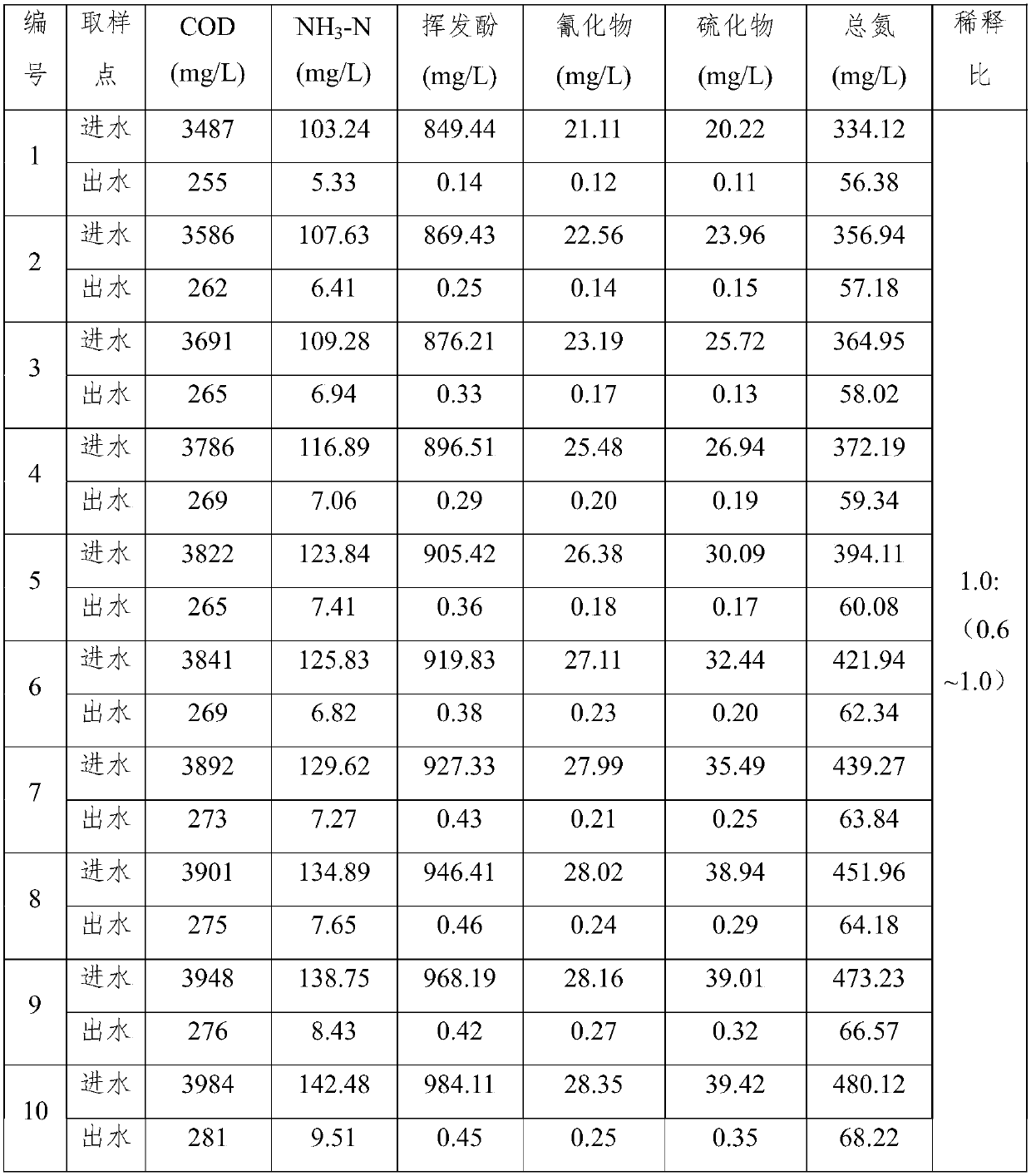

[0059] Fix the polyethylene / formylated vinylon composite wire on a plastic ring with a diameter of 170mm to form a faceplate, and fix the faceplate on the central rope through a sleeve with a length of 120mm at intervals to make a biological carrier component, and reserve 350mm at both ends of the biological carrier component center rope.

[0060] Fix the submersible mixer on the side wall at the diagonal bottom of the sump. The height of the designed biological carrier support is 1.8m, the distance between the suspension beams on the biological carrier support is 0.22m, and the length and width of the biological carrier support are determined according to the length and width of the sewage pool. The biological carrier bracket is fixed in the sewage pool, the bottom of the biological carrier bracket is 0.8m away from the bottom of the sewage pool, and the top of the biological carrier bracket is 1.2mm away from the top of the sewage pool.

[0061] Fix the biocarrier assembly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com