Low-radiation hollow glass with ultraviolet blocking effect

A barrier effect and low-radiation technology, applied in the direction of coating, etc., can solve the problems of appearance color difference, difficult molding, limited molding shape, etc., to enhance the proportion of reflected ultraviolet rays, reduce the low transmittance of the film layer, and good thermal insulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

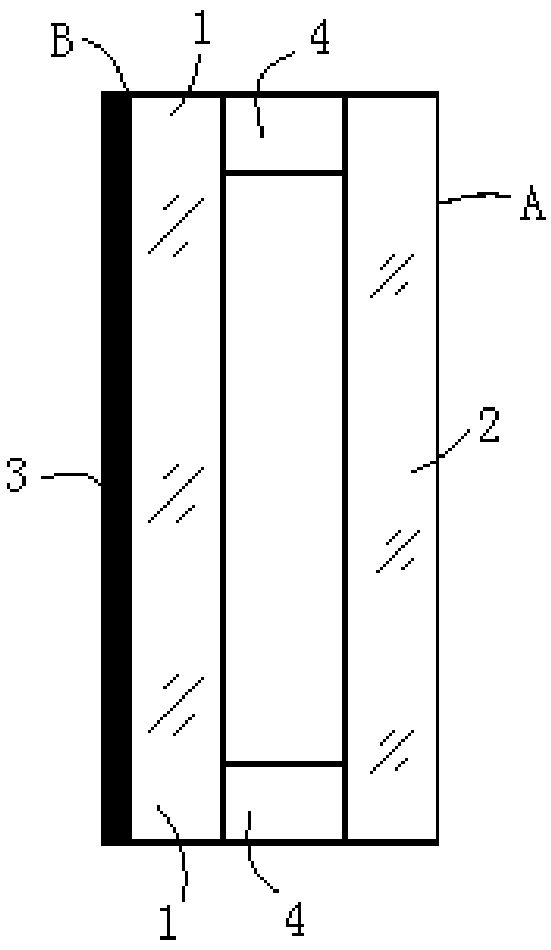

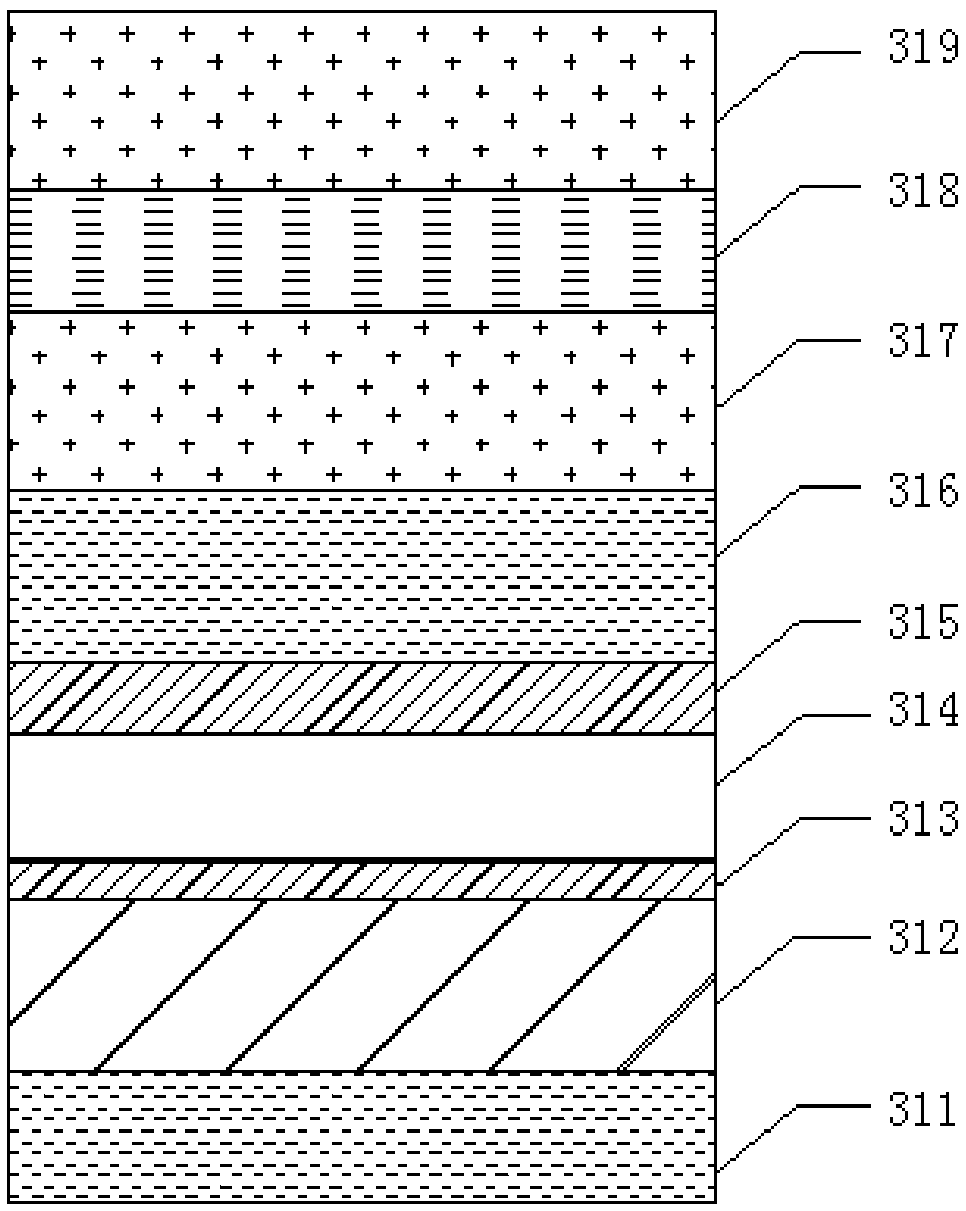

[0069] This embodiment provides a low-radiation energy-saving insulating glass product with low-radiation ultraviolet radiation, specifically figure 1 The hollow structure. Use our company's 6mm float white glass as the glass substrate, and the surface of one of the float white glass substrates is vacuum sputtered to obtain the ultraviolet blocking low-radiation composite functional film layer 3, and the film layer structure is as follows: figure 2 shown.

[0070] Among them, the structure of the composite functional film layer coated on the surface of the outer wall is based on the first glass substrate 1, which is sequentially processed from the inside to the outside from the surface of the substrate: the bottom SiNx layer 311, the second ZnO layer 312, the third layer NiCr alloy layer 313, fourth Ag layer 314, fifth NiCr layer 315, sixth SiNx layer 316, seventh SiOx layer 317, eighth TiOx layer 318 and ninth SiOx layer 319.

[0071] The above-mentioned composite film st...

Embodiment 2

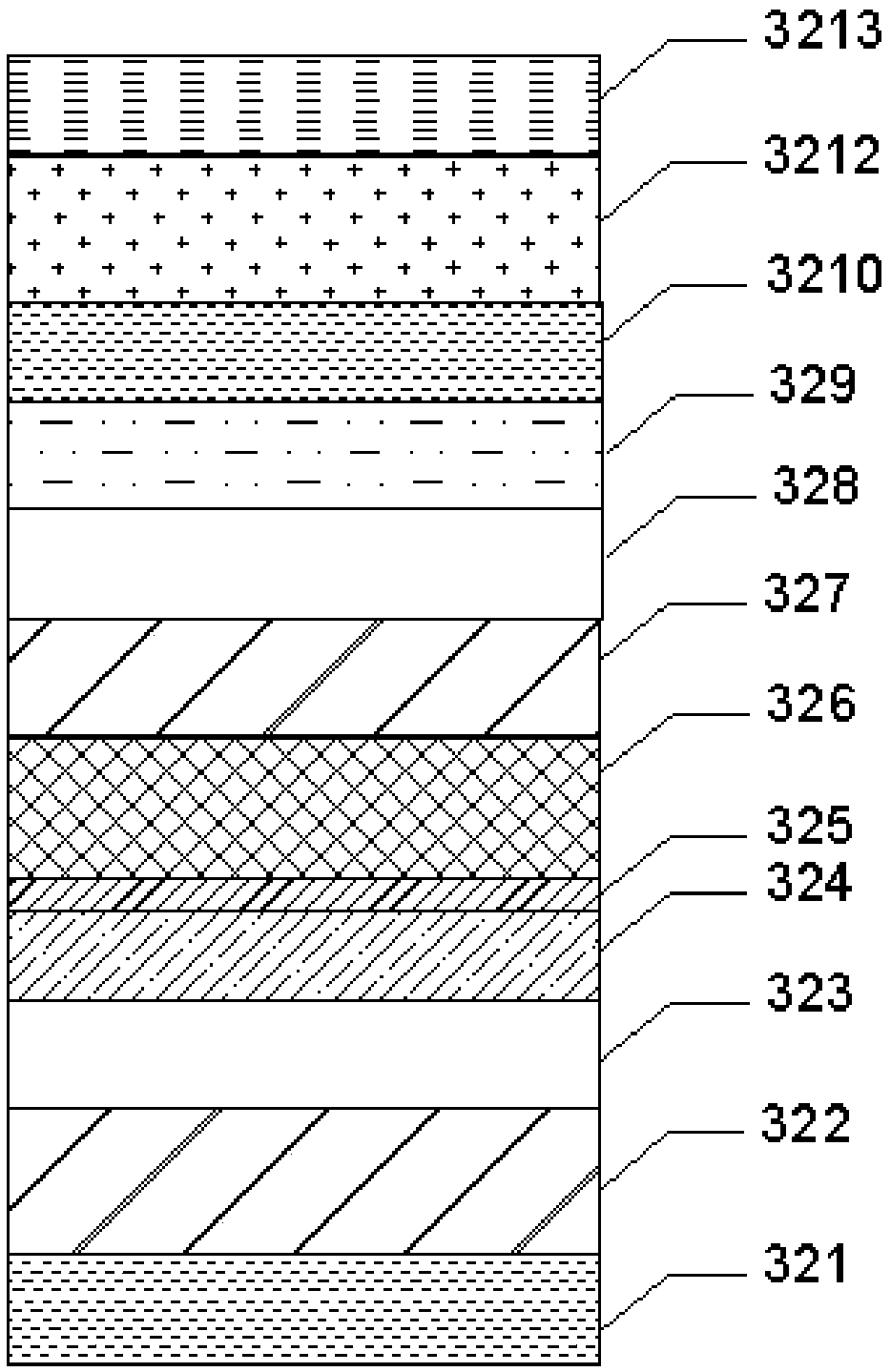

[0078] This embodiment provides another low-radiation and energy-saving insulating glass product with low-radiation ultraviolet radiation. Its structure is as follows: figure 1 As shown in the figure, two pieces of 6mm float glass are used as substrates, which are arranged opposite to each other and combined with a hollow glass frame to construct a product with a hollow structure. Among them, the glass substrate surface processing on the exterior wall surface has image 3 The film layer structure of the UV-blocking low-radiation composite functional film layer 3 shown.

[0079] The structure of the composite functional film layer 3 processed on the glass substrate on the surface of the outer wall is based on the inner surface of the first glass substrate 1, starting from the base from the inside to the outside: the bottom layer SiNx layer 321, the second layer ZnO layer 322, the third layer of Ag layer 323, the fourth layer of Cu layer 324, the fifth layer of NiCr alloy laye...

Embodiment 3

[0085] This embodiment provides a low-radiation and energy-saving hollow glass product with ultraviolet low-radiation effect. The structure of the hollow glass is as follows: figure 1 shown. Two pieces of float white glass arranged oppositely are used as substrates, and the two float glass substrates are processed by frame 4 to form a hollow structure. The surface of one of the float white glass substrates is processed with an ultraviolet blocking low-radiation composite functional film layer 3, and the composite functional film layer structure is as follows: Figure 4 shown.

[0086] The composite functional film layer structure is based on the inner surface of the first glass substrate 1, and is obtained by vacuum sputtering from the inside to the outside from the base surface: the bottom SiNx layer 331, the second ZnO layer 332, the third Ag layer 333, the fourth layer of AZO layer 334, the fifth layer of ZnSnOx layer 335, the sixth layer of ZnO layer 336, the seventh la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com