Method for recycling unqualified emulsion explosive, and emulsion explosive

An emulsion explosive, qualified technology, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of unsafe production process, low processing efficiency, unsafety, etc., and achieve the effect of simple recycling steps and safe preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

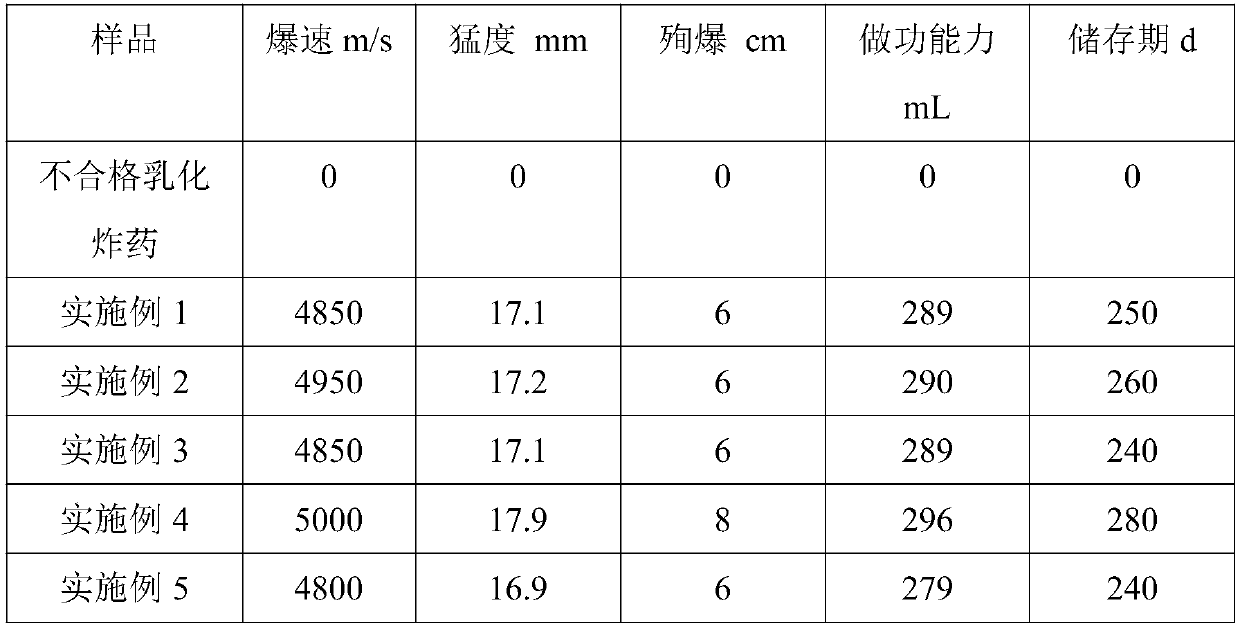

Examples

Embodiment 1

[0025] Add 500kg of unqualified emulsion explosives into an 800L silo and heat to 95°C, then transport it to the SV static mixer through a single-screw pump for intensive milking, and control the speed of the screw pump so that the residence time of the material in the static mixer reaches 2s. Then cool the finished semi-finished product to 88°C, add 0.75kg of 40% sodium nitrite solution, mix uniformly for 1min, then add 0.5kg of 40% phosphoric acid solution, mix uniformly for 1min before charging.

Embodiment 2

[0027] Add 400kg of unqualified emulsion explosives into an 800L silo and heat to 93°C, then transport it to the SV static mixer through a single-screw pump for intensive milking, and control the speed of the screw pump so that the residence time of the material in the static mixer reaches 3s. Then cool the semi-finished product after essence milk to 87°C, add 0.76kg of 40% sodium nitrite solution, mix uniformly for 1min, then add 0.51kg of 40% phosphoric acid solution, mix uniformly for 1min before charging.

Embodiment 3

[0029] Add 600kg of unqualified emulsion explosives into the 800L silo and heat it to 97°C, then transport it to the SV static mixer through a single-screw pump for fine milk, and control the speed of the screw pump so that the residence time of the material in the static mixer reaches 1.5s , then cool the semi-finished product after essence milk to 89°C, add 0.73kg of 40% sodium nitrite solution, mix uniformly for 1min, then add 0.46kg of 40% phosphoric acid solution, mix uniformly for 1min, and then charge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com