Method of immobilizing beta-fructofuranosidase and glucose oxidase by sol-gel process

A technology of fructofuranosidase and glucose oxidase, which is applied in the field of enzyme engineering, can solve the problems of inability to immobilize other enzymes, decrease in enzyme activity, and application limitations, and achieve improved yield of lactulose oligosaccharides, good stability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

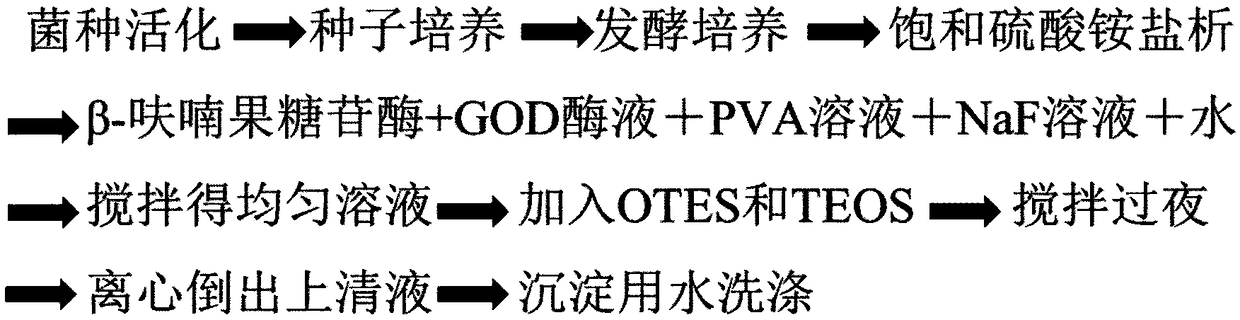

Method used

Image

Examples

Embodiment 1

[0046] First activate the Arthrobacter sp.10137 strain, insert the preserved Arthrobacter into the activation medium (glucose 2% (w / v); yeast extract 0.15% (w / v); magnesium sulfate 0.01% (w / v); Potassium dihydrogen phosphate 0.2% (w / v); diammonium hydrogen phosphate 0.6% (w / v); pH7.0-7.2), cultured at 30° C. for 24 hours to obtain activated strains. Carry out seed culture afterwards, draw the bacterial classification after 1ml activation to house 100ml seed culture medium (glucose 2% (w / v); Yeast extract 0.15% (w / v); Peptone 0.3% (w / v); Magnesium sulfate 0.01% (w / v); Potassium dihydrogen phosphate 0.2% (w / v); Diammonium hydrogen phosphate 0.6% (w / v), pH7.0-7.2) in a 250ml Erlenmeyer flask, in a shaker for 30 Cultivate at ℃ for 24h, with a shaking speed of 125r / min. Carry out fermentation culture then, seed culture solution is connected with 100ml fermentation medium (sucrose 4% (w / v); Yeast extract 1.2% (w / v): peptone 0.8% (w / v) by 2% inoculum size access ); Magnesium sulfat...

Embodiment 2

[0050] First activate the Arthrobacter sp.10137 strain, insert the preserved Arthrobacter into the activation medium (glucose 2% (w / v); yeast extract 0.15% (w / v); magnesium sulfate 0.01% (w / v); Potassium dihydrogen phosphate 0.2% (w / v); diammonium hydrogen phosphate 0.6% (w / v); pH7.0-7.2), cultured at 30° C. for 24 hours to obtain activated strains. Carry out seed culture afterwards, draw the bacterial classification after 1ml activation to house 100ml seed culture medium (glucose 2% (w / v); Yeast extract 0.15% (w / v); Peptone 0.3% (w / v); Magnesium sulfate 0.01% (w / v); Potassium dihydrogen phosphate 0.2% (w / v); Diammonium hydrogen phosphate 0.6% (w / v), pH7.0-7.2) in a 250ml Erlenmeyer flask, in a shaker for 30 Cultivate at ℃ for 24h, with a shaking speed of 125r / min. Carry out fermented culture then, seed culture liquid is connected with 100ml fermentation medium (sucrose 4% (w / v); Yeast extract 1.2% (w / v): peptone 0.8% (w / v) by 3% inoculum size access ); Magnesium sulfate 0.2...

Embodiment 3

[0054] First activate the Arthrobacter sp.10137 strain, insert the preserved Arthrobacter into the activation medium (glucose 2% (w / v); yeast extract 0.15% (w / v); magnesium sulfate 0.01% (w / v); Potassium dihydrogen phosphate 0.2% (w / v); diammonium hydrogen phosphate 0.6% (w / v); pH7.0-7.2), cultured at 30° C. for 24 hours to obtain activated strains. Carry out seed culture afterwards, draw the bacterial classification after 1ml activation to house 100ml seed culture medium (glucose 2% (w / v); Yeast extract 0.15% (w / v); Peptone 0.3% (w / v); Magnesium sulfate 0.01% (w / v); Potassium dihydrogen phosphate 0.2% (w / v); Diammonium hydrogen phosphate 0.6% (w / v), pH7.0-7.2) in a 250ml Erlenmeyer flask, in a shaker for 30 Cultivate at ℃ for 24h, with a shaking speed of 125r / min. Carry out fermented culture then, seed culture solution is connected with 100ml fermentation medium (sucrose 4% (w / v); Yeast extract 1.2% (w / v): peptone 0.8% (w / v) by 4% inoculum size access ); Magnesium sulfate 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com