Surface treatment process of 6063 aluminum alloy profile

An aluminum alloy profile and surface treatment technology, applied in anodizing and other directions, can solve the problems of high environmental pollution of 6063 aluminum alloy profiles, low production quality of 6063 aluminum alloy profiles, poor corrosion resistance and wear resistance, etc. Reduction efficiency, high utilization rate, and the effect of saving aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

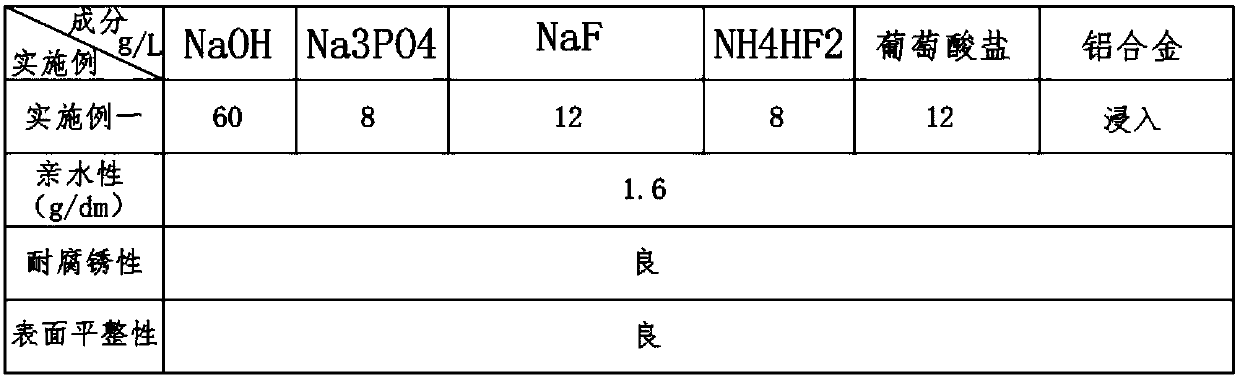

Embodiment 1

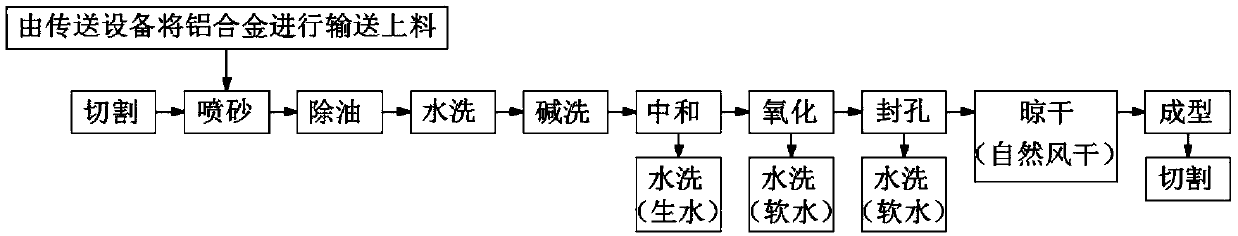

[0035] A surface treatment process for 6063 aluminum alloy profiles, comprising the following steps:

[0036] Step A: cutting, first cut the 6063 aluminum alloy that needs to be polished at equal distances through cutting equipment according to the processing requirements, and cut the cross-section of the 6063 aluminum alloy flat by vertical cutting method;

[0037] Step B: sandblasting, the cut 6063 aluminum alloy materials are transported forward one by one through the transmission equipment, the transmission equipment passes through the inside of the sandblasting box, and there are channels on both sides of the sandblasting box, and the transmission equipment supports the 6063 aluminum alloy through the The channel enters the interior of the sandblasting box. When the 6063 aluminum alloy material enters the sandblasting box, the two ends of the 6063 aluminum alloy material are connected and supported by two clamps. The two clamps move away from the end of the 6063 aluminum a...

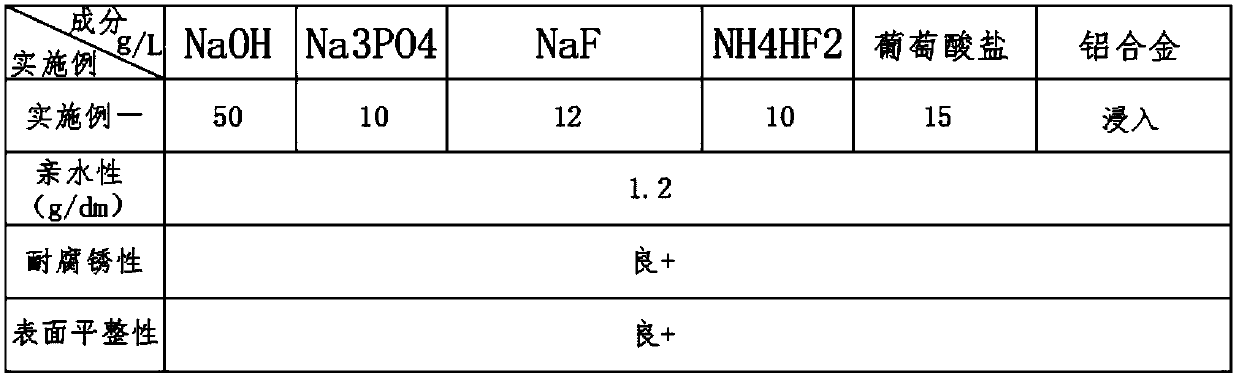

Embodiment 2

[0049] A surface treatment process for 6063 aluminum alloy profiles, comprising the following steps:

[0050] Step A: cutting, first cut the 6063 aluminum alloy that needs to be polished at equal distances through cutting equipment according to the processing requirements, and cut the cross-section of the 6063 aluminum alloy flat by vertical cutting method;

[0051] Step B: sandblasting, the cut 6063 aluminum alloy materials are transported forward one by one through the transmission equipment, the transmission equipment passes through the inside of the sandblasting box, and there are channels on both sides of the sandblasting box, and the transmission equipment supports the 6063 aluminum alloy through the The channel enters the interior of the sandblasting box. When the 6063 aluminum alloy material enters the sandblasting box, the two ends of the 6063 aluminum alloy material are connected and supported by two clamps. The two clamps move away from the end of the 6063 aluminum a...

Embodiment 3

[0063] A surface treatment process for 6063 aluminum alloy profiles, comprising the following steps:

[0064] Step A: cutting, first cut the 6063 aluminum alloy that needs to be polished at equal distances through cutting equipment according to the processing requirements, and cut the cross-section of the 6063 aluminum alloy flat by vertical cutting method;

[0065] Step B: sandblasting, the cut 6063 aluminum alloy materials are transported forward one by one through the transmission equipment, the transmission equipment passes through the inside of the sandblasting box, and there are channels on both sides of the sandblasting box, and the transmission equipment supports the 6063 aluminum alloy through the The channel enters the interior of the sandblasting box. When the 6063 aluminum alloy material enters the sandblasting box, the two ends of the 6063 aluminum alloy material are connected and supported by two clamps. The two clamps move away from the end of the 6063 aluminum a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com